Aluminium Panels and Flaps

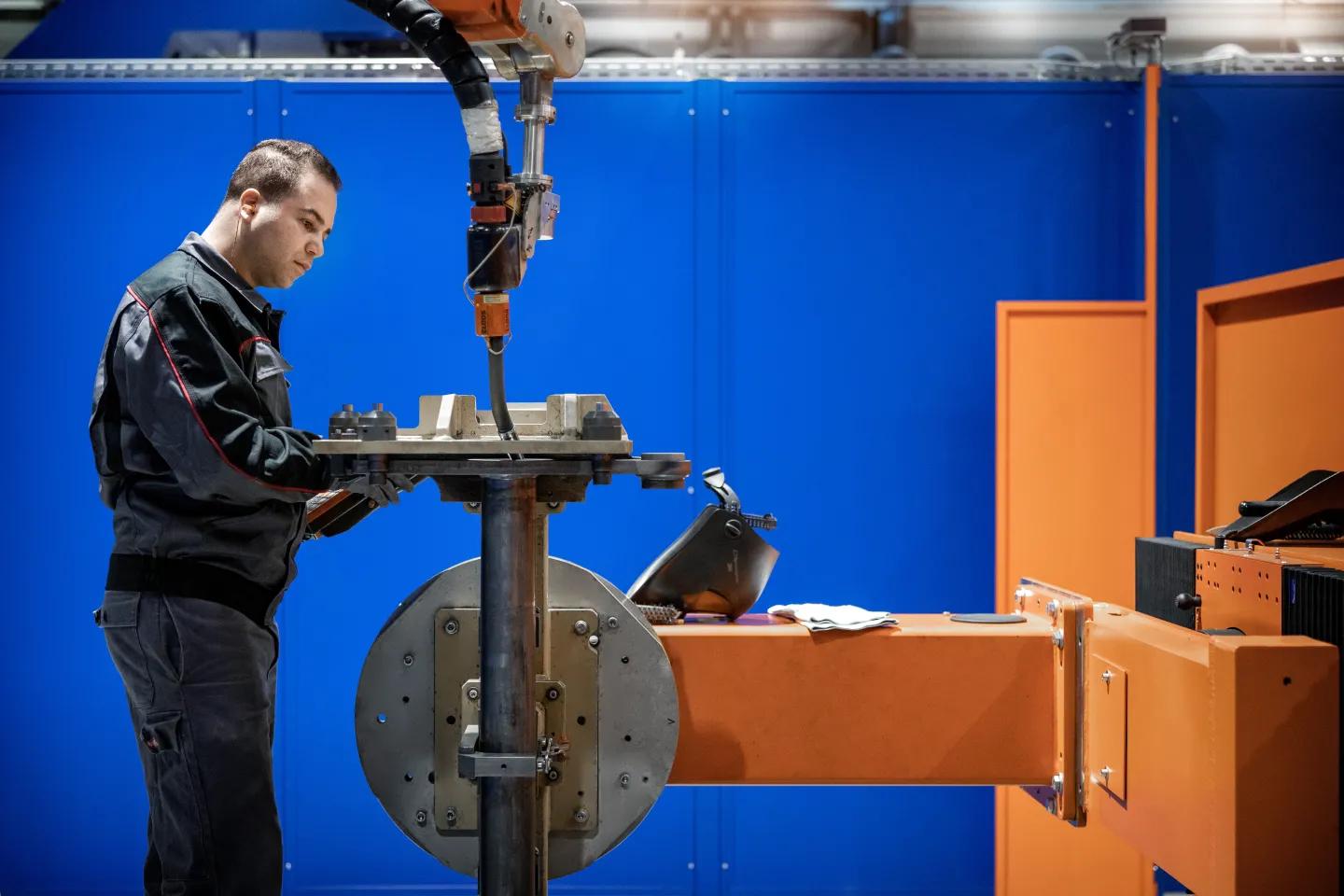

In addition to tanks, the production of luggage compartment and fuel filler flaps as well as panels made from aluminium for buses and commercial vehicles is another of our core competencies. For example, all Setra coaches delivered in the last 20 years are equipped with our flaps and today we look after the replacement parts business for these. We deliver ready-to-install flap systems made from aluminium in accordance with customer requirements. It goes without saying that we develop flap concepts together with our customers taking into the account the functionality and weight optimisation.

Our range of services covers the following:

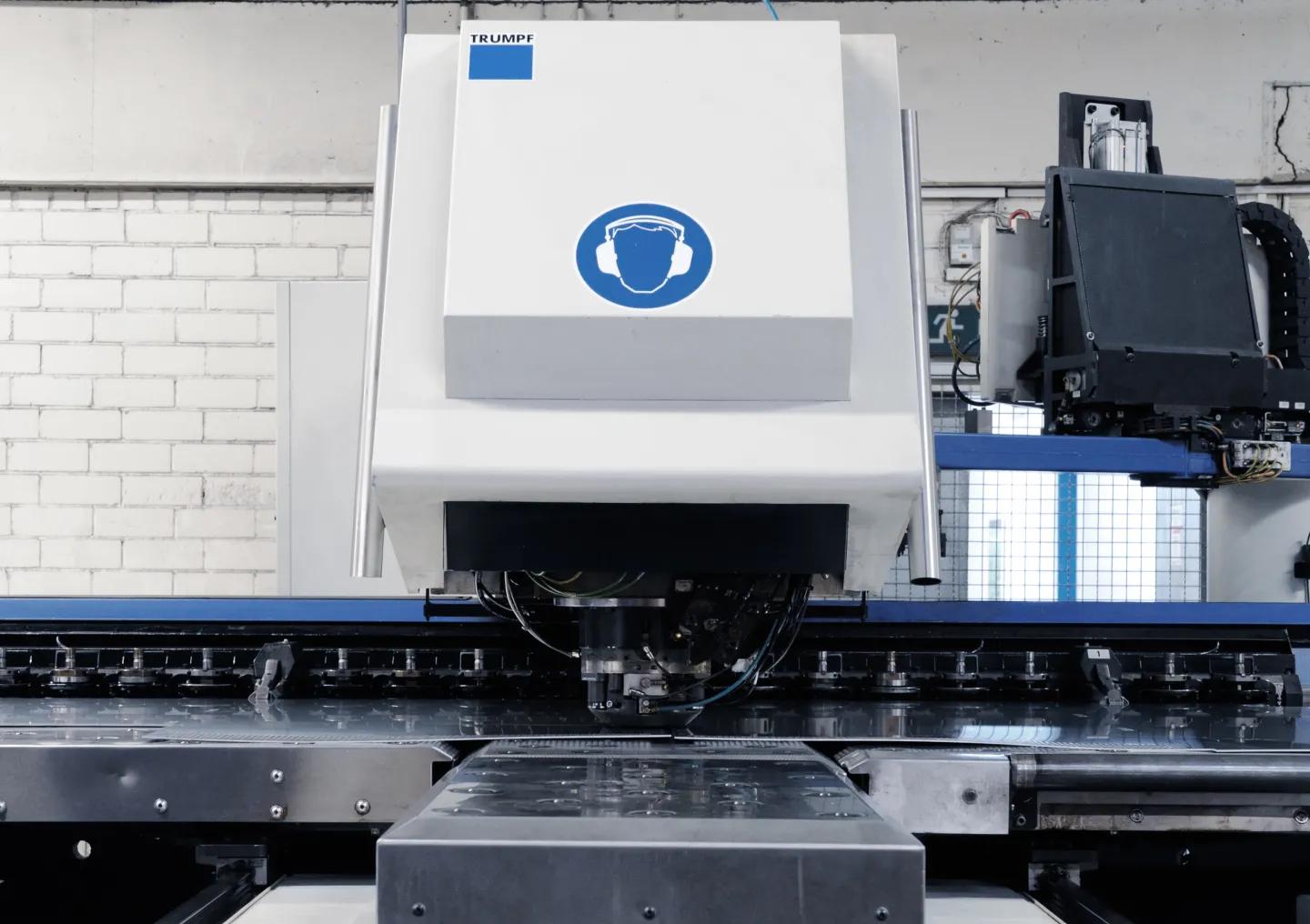

- Programming and blanking

- Milling and forming (rounding, edging, rolling in)

- Alignment and grinding

- Pretreatment and powder coating

- Adhesive bonding, sealing and assembly

- Quality control and proper packaging

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Eislingen here.

Certifications

With a comprehensive level of service, we deliver the components and systems just-in-time or just-in-sequence – upon request also in a vehicle-related manner (one-set flow) – directly to the assembly line of our customers.

Our production system is geared towards the usual high number of variants and batch size of one associated with commercial vehicles together with the restriction of short throughput times and a desired delivery performance of 100%. In this connection, we constantly monitor the entire supply chain by means of our ERP system in order to have the required direct material available at the required point in time.

Our range of services covers the following:

- Individually coordinated logistics concepts

- Just-in-time or just-in-sequence deliveries

- Vehicle-related deliveries (one-set flow)

- Deliveries starting at a quantity of 1+x

- Customs declaration and clearing

HÖRMANN Automotive supports value-based transparency and performance as well as a structured way of working so that we can focus on the requirements of the automotive and commercial vehicle industries with the highest quality standards while complying with the occupational safety and environmental management systems.

We see change as an opportunity!

We take a proactive approach to the demands placed on our business model by changing markets, volatile customer requirements, numerous product changes, complex, multi-variant customer products and climate change. We respond to changes promptly and continuously optimise our processes to achieve new target states.

Decoupled shifts with demand-orientated shift ends and quality-conscious, well-trained and flexible employees ensure that the product quantity required by the customer is always guaranteed to be available on the delivery date. All our processes are equipped with the necessary emergency concepts to ensure that we are able to deliver at all times. The same applies to our IT systems. Customer call-offs are received via our SAP system and forwarded to all suppliers accordingly.

Social responsibility

In order to fulfil our social responsibility, we are committed to protecting the environment in the sense of the circular economy, from the selection of resources to the recycling-friendly product concept. We communicate this to our partners. It is also our aim to make our employees' workplaces safe and liveable by minimising the use of hazardous substances and reducing risks, and to maintain them in the long term.

For all products and services, working in accordance with various quality standards ensures globally recognised and certified, sustainable quality and reliability, which is checked and guaranteed through regular inspections and audits as well as continuous further development. In this way, we continuously create added value for our customers.

Our environmental management system is certified according to various standards. We strive for continuous improvement and further development. The environmental management system is continuously re-evaluated and we are always on the lookout for new ways to further conserve resources and the environment.

In line with our company quality, occupational health and safety management, we actively approach our employees and involve them in our decision-making. We take our social responsibility as a company very seriously. This is why sustainability and environmental protection play an important role in our corporate philosophy. Consequently, we use energy and resources responsibly and efficiently.

Certificates HÖRMANN Automotive Banovce

Certificates HÖRMANN Automotive Gustavsburg

ISO 14001:2015

ISO 50001:2018

IATF 16949:2016

DIN EN ISO 3834-2:2021

TISAX® Assessment Scope S71K15

Sustainability Rating

Certificates HÖRMANN Automotive Saarbrücken

ISO 9001:2015

IATF 16949:2016

ISO 3834-2:2021, Industriestr. 2, Sulzbach

ISO 3834-2:2021, Zur Tannenburg 31, Sulzbach

Certificates HÖRMANN Automotive St. Wendel

IATF 16949:2016

Certificates HÖRMANN Automotive Wackersdorf

IATF 16949:2016

Certificates

With a comprehensive level of service, we deliver the components and systems just-in-time or just-in-sequence – upon request also in a vehicle-related manner (one-set flow) – directly to the assembly line of our customers.

Our production system is geared towards the usual high number of variants and batch size of one associated with commercial vehicles together with the restriction of short throughput times and a desired delivery performance of 100%. In this connection, we constantly monitor the entire supply chain by means of our ERP system in order to have the required direct material available at the required point in time.

Our range of services covers the following:

- Individually coordinated logistics concepts

- Just-in-time or just-in-sequence deliveries

- Vehicle-related deliveries (one-set flow)

- Deliveries starting at a quantity of 1+x

- Customs declaration and clearing

HÖRMANN Automotive supports value-based transparency and performance as well as a structured way of working so that we can focus on the requirements of the automotive and commercial vehicle industries with the highest quality standards while complying with the occupational safety and environmental management systems.

We see change as an opportunity! We are pro-actively tackling the requirements being placed on our business model by changing markets, volatile customer requirements, numerous product changes, complex customer products with numerous variants as well as climate change. We face up to the changes promptly and continuously optimise our processes to achieve new target states.

Due to decoupled shifts with a demand-oriented end of shift as well as quality-conscious, well-trained and flexibly deployable employees, it can always be ensured that the product quantities demanded by the customer are available as per the delivery date. All our processes have the required contingency plans in order to be in the position to deliver at all times. This equally applies to our IT systems. Customer release orders are received via our SAP system and accordingly forwarded to all suppliers.

To fulfil our social responsibility, we undertake to protect the environment through a circular economy, starting with the selection of the resources up to a recycling-compatible product concept. We also communicate this onto our partners. It is similarly our goal to design the workplaces of our employees so that they are safe and attractive via the minimal use of hazardous materials and reduced exposure to hazards and to safeguard them in the long term.

For all products and services, the work to various different quality standards ensures a globally recognised and certified as well as sustainable quality and reliability that is checked and guaranteed via regular shopfloor visits and audits as well as constant further development. In this way, we continuously create added value for our customers.

Our environmental management system is certified to various different standards. We strive for continuous improvement and further development. The environmental management system is continuously re-evaluated and we are always on the lookout for new ways to further conserve resources and protect the environment.

In accordance with the operational quality, occupational safety and health management systems, we actively approach our employees and involve them in our decision-making. We take our social responsibility as a company very seriously. This is why sustainability and the protection of the environment play an important role in our corporate philosophy. As a result, we use energy and resources in a responsible and efficient manner.

Leitlinien

IATF 16949:2016

IATF 16949:2016

IATF 16949:2016

IATF 16949:2016

ISO 14001:2015

ISO 9001:2015

ISO 9001:2015

ISO 9001:2015

ISO 14001:2015

ISO 14001:2015

ISO 50001:2011

ISO 50001:2011

DIN V 4113-3:2011

DIN EN ISO 3834-2:2006

References for E-Mobility

The electrification of the drive world is continuing unabated – whether as hybrid or fully electric. The electric drive is no longer just for passenger car traffic: Hybrid and electric buses also are winning over admirers with less noise and lower consumption. Commercial vehicles can thus drive into city centres in spite of environmental zones and night-time noise restrictions.

HÖRMANN Automotive sees itself as a competent supplier and contact for the following topics:

- Charging infrastructure

- Micromobility

- Innovative battery carrier concepts

To be able to support the trend topic of “e-mobility” to the maximum, the infrastructure is key as the system can only function with this. HÖRMANN Automotive is positioning itself as a neutral industrialiser and assembly service provider for charging stations, for example. The plant in Wackersdorf current offers the D Module (production quality assurance certificate).

The discussions about climate protection and the change in the automotive sector are also resulting in new players in the market. HÖRMANN Automotive defines micromobility as small electric vehicles for urban life and the last mile. In this connection, new automotive OEMs and products such as the e-scooter are appearing on the market. HÖRMANN Automotive is also present here as a neutral industrialiser & assembly service provider. The plant in Wackersdorf is using its experience of recent years here and is implementing quality standards for the customers.

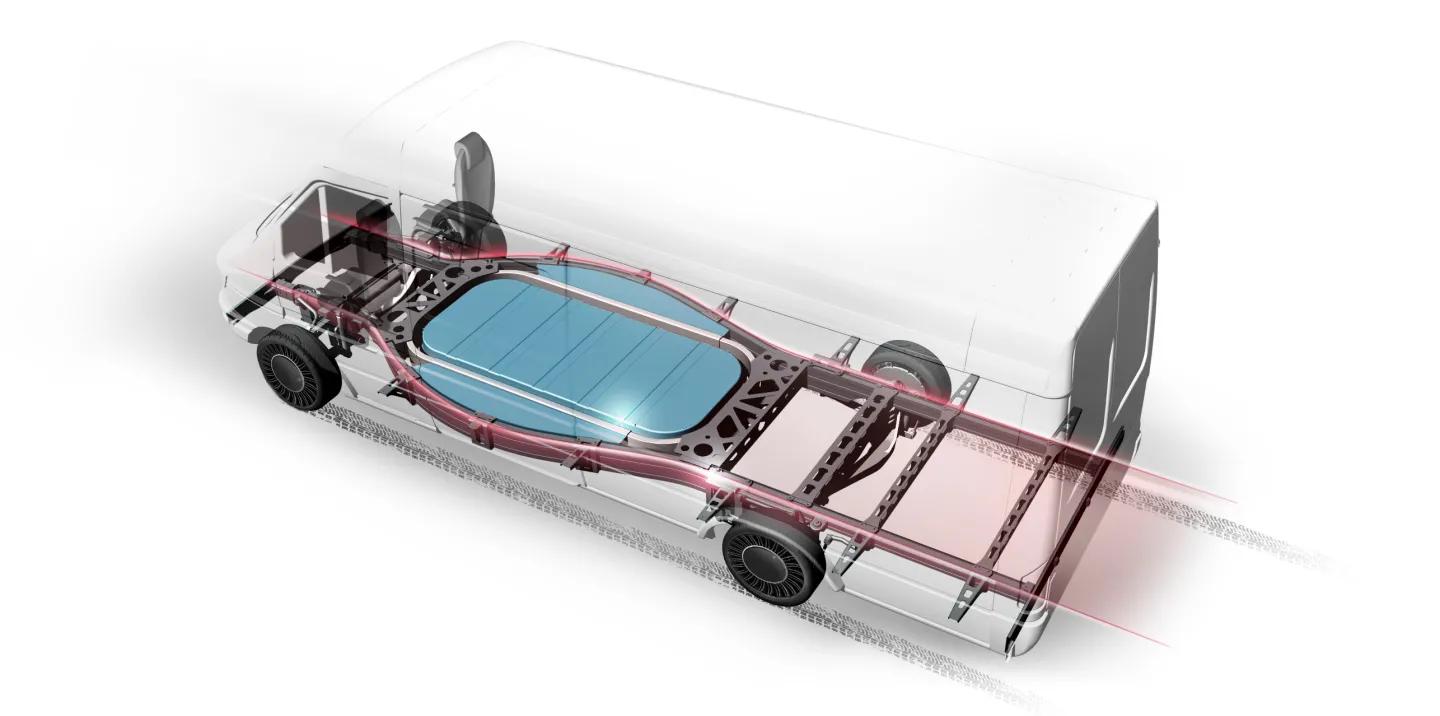

Our focus lies in particular on the innovative battery concepts. The chassis for light commercial vehicles (LCV) in the “Last Mile” area of HÖRMANN Automotive is characterised by a bionic lightweight design approach that can be seen both in the topology and in the component design. The non-linear chassis topology facilitates systemic protection of the energy storage units in the chassis and thus reduces the weight and costs for the accommodation and protection of the batteries. The non-linear longitudinal members are made in turn from steel multi-chamber profiles that are designed specifically for the absorption of impact energy in the case of a side crash. The underlying, innovative production technology allows a high number of variants in the profile configuration without additional tooling costs and is thus able to cover a high number of vehicle variants with regard to the wheelbase and battery dimensions. The vehicle is equipped with wheel hub direct drives and thus has a reduced entrance height and at the same time maximises the potential loading volume of the body.

In this connection, HÖRMANN Automotive sees itself as a system partner of customers – from the development to the production of innovative thick plate concepts, welded components, fine sheets for body parts to the assembly of mechanical and mechatronic assemblies. We orientate all processes to customer requests and adapt them accordingly. Thanks to the cooperation in what are known as ecosystems with established system suppliers as well as start-ups, highly innovative solutions are developed for the electromobility of the future.

Customers

References for Forklift Trucks

Goods go nowhere without it – the forklift truck! The scopes of application of this means of transport are diverse. They are used in retail and in industry as well as in logistics centres. The range of products on offer is accordingly wide. It extends from manually operated pallet lift trucks to forklifts with electric motors, gas or diesel engines to heavy-duty lift trucks with a load-carrying capacity of 50 tonnes.

What do we produce for the forklift truck sector?

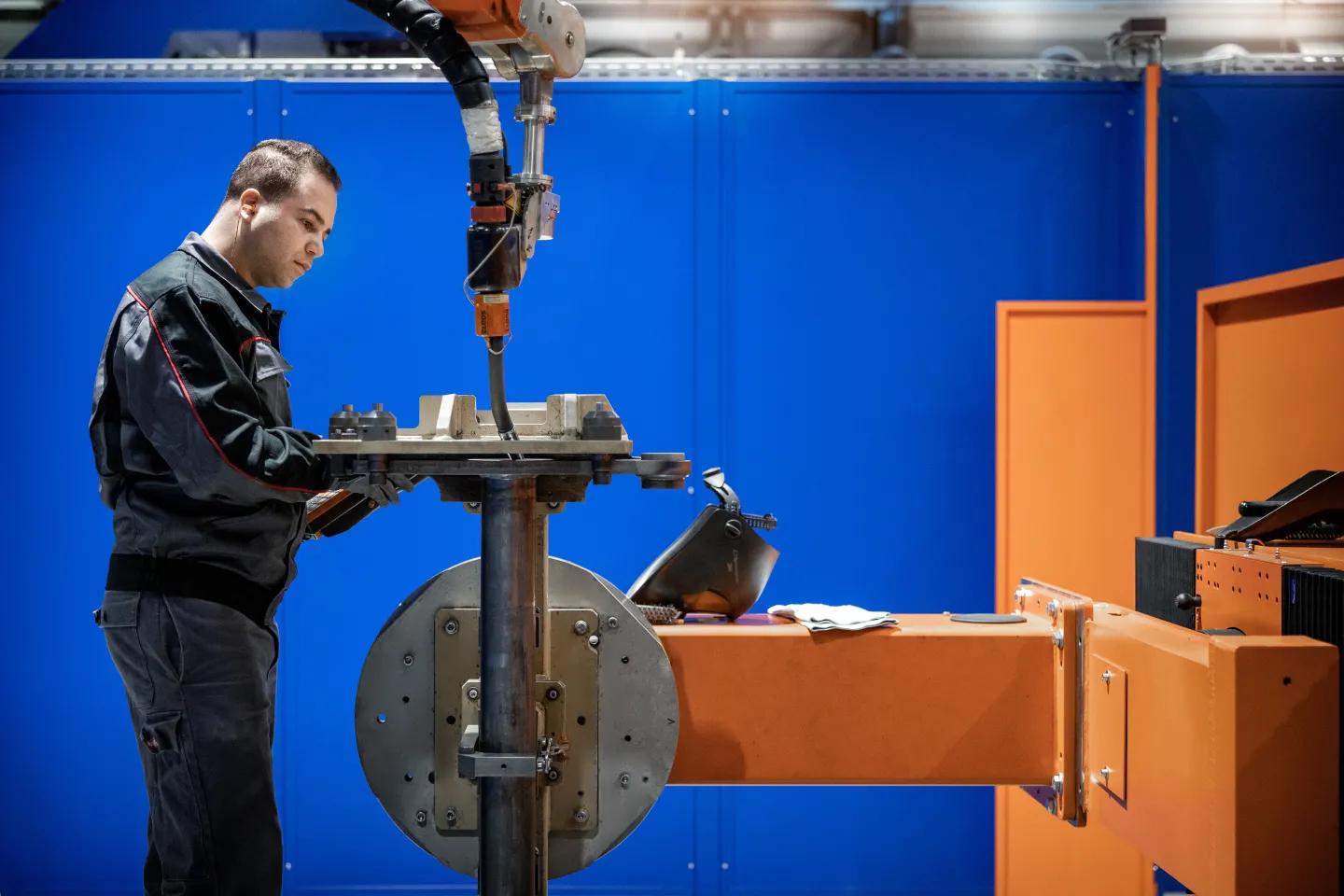

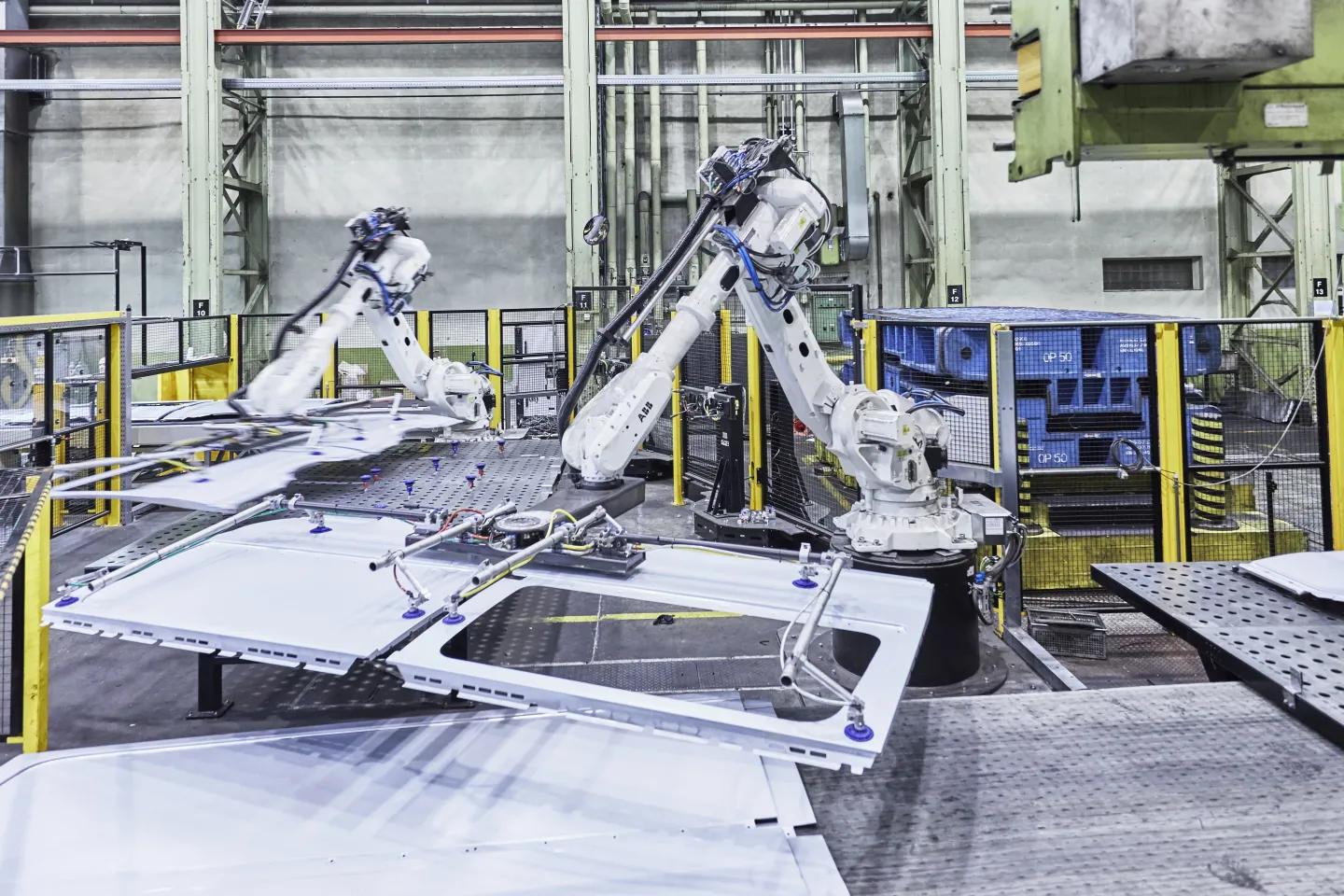

HÖRMANN Automotive delivers welded assemblies in low, medium and high volumes. We advise our customers already in the offer process in order to achieve the best result for the final customer together. A wide range of simultaneous engineering instruments is available to us, with the help of which the development times can be minimised and the quality of the components can be influenced as early as in the product creation process.

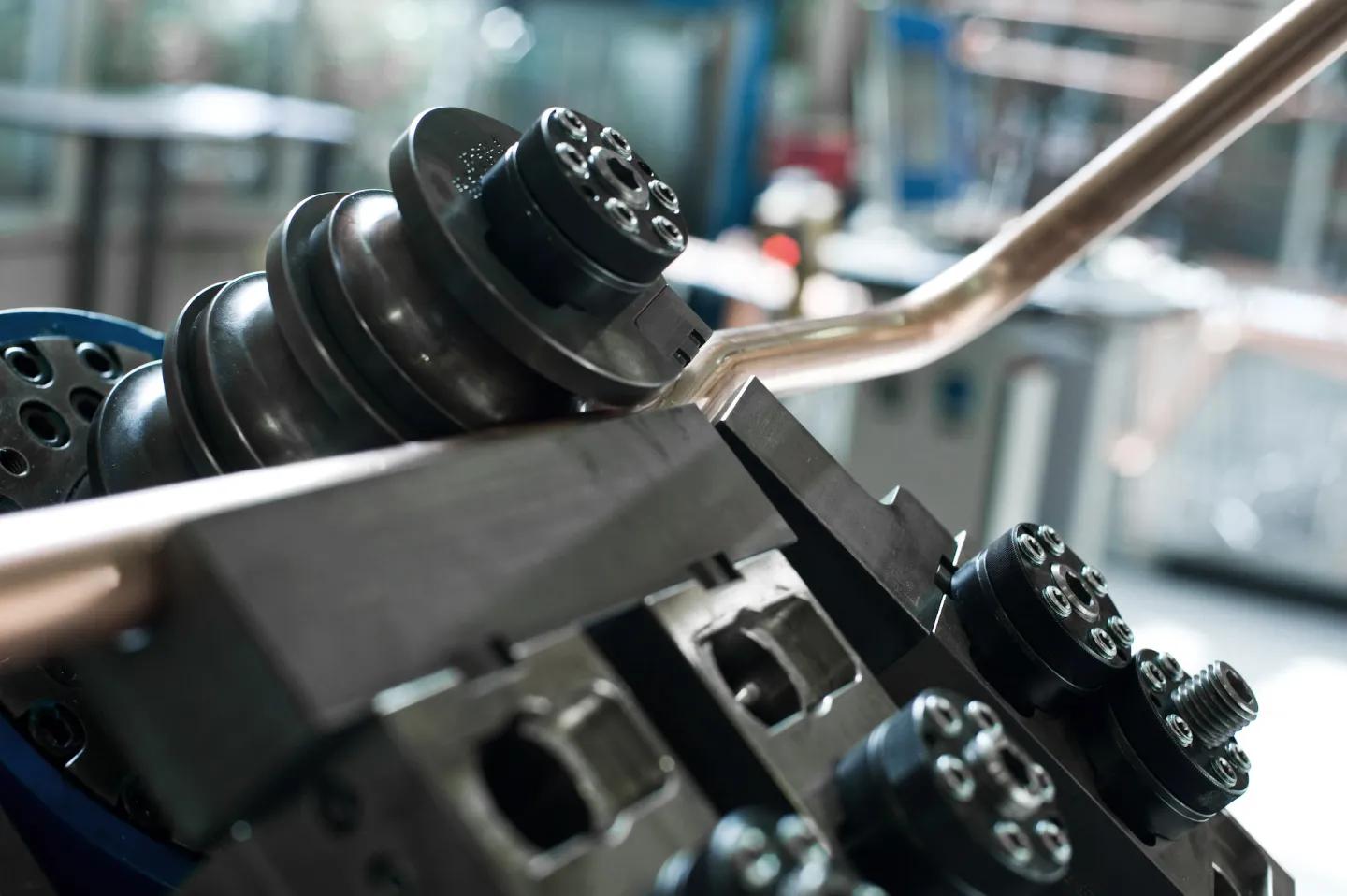

The single part production (2D/3D lasering, nibbling, edging, rolling, bending, forming, deep-drawing) upstream of the welding process as well as the production and procurement of the required jigs and fixtures are part of the range of services provided by HÖRMANN Automotive. Our expertise when it comes to manual and semi-automated welding processes and the mastering of fully automated production in the high-volume sector are clear proof of our extensive range of services in the welded assembly sector. If required, we also deliver painted assemblies and systems JIT/JIS directly to the assembly line of our customers.

References for Buses

Goods go nowhere without it – the forklift truck! The scopes of application of this means of transport are diverse. They are used in retail and in industry as well as in logistics centres. The range of products on offer is accordingly wide. It extends from manually operated pallet lift trucks to forklifts with electric motors, gas or diesel engines to heavy-duty lift trucks with a load-carrying capacity of 50 tonnes.

What do we produce for the forklift truck sector?

HÖRMANN Automotive delivers welded assemblies in low, medium and high volumes. We advise our customers already in the offer process in order to achieve the best result for the final customer together. A wide range of simultaneous engineering instruments is available to us, with the help of which the development times can be minimised and the quality of the components can be influenced as early as in the product creation process.

The single part production (2D/3D lasering, nibbling, edging, rolling, bending, forming, deep-drawing) upstream of the welding process as well as the production and procurement of the required jigs and fixtures are part of the range of services provided by HÖRMANN Automotive. Our expertise when it comes to manual and semi-automated welding processes and the mastering of fully automated production in the high-volume sector are clear proof of our extensive range of services in the welded assembly sector. If required, we also deliver painted assemblies and systems JIT/JIS directly to the assembly line of our customers.

References for Construction Machinery

The German construction machinery industry encompasses mining, construction and construction material machinery. It is used for construction projects, the transport of auxiliary construction materials and the processing of construction materials. The range here extends from diggers to conveyors to fixed-location equipment. With approximately 32%, earthmoving equipment is one of the most important machinery categories in the overall sector turnover. This includes hydraulic excavators.

What do we produce for the construction machinery sector?

HÖRMANN Automotive produces hydraulic tanks of up to 1,600 l as an integral part of the equipment system including the colour scheme and JIT/JIS delivery. These complex and sophisticated systems are often subject to very high technical requirements.

We are known at our customers in the sector for fully assembled, ready-to-install systems – produced in low volumes with a very high number of production variants. HÖRMANN Automotive is equipped for the customer needs, which often come in at short notice, and has aligned the procurement logistics and production processes to reflect this. Our competent and flexible employees make a huge contribution here.

It is important to us to know the qualitative, technical and time-related challenges of our customers in order to fulfil the expectations as a recognised system supplier with this knowledge. For our customers, we are an innovative, competitive and reliable supplier that helps shape their success on a partnership basis.

Customers

References for Agricultural Machinery

The German agricultural machinery industry is one of the ten largest special sectors in mechanical engineering. Due to its high level of innovation and production quality, it also has an excellent competitive position internationally. The industrial sector has undergone a period of stable further development in recent years – in spite of crisis situations abroad. Almost every eighth employee in Germany is active in the agricultural and food industries.

What do we produce for the agricultural machinery sector?

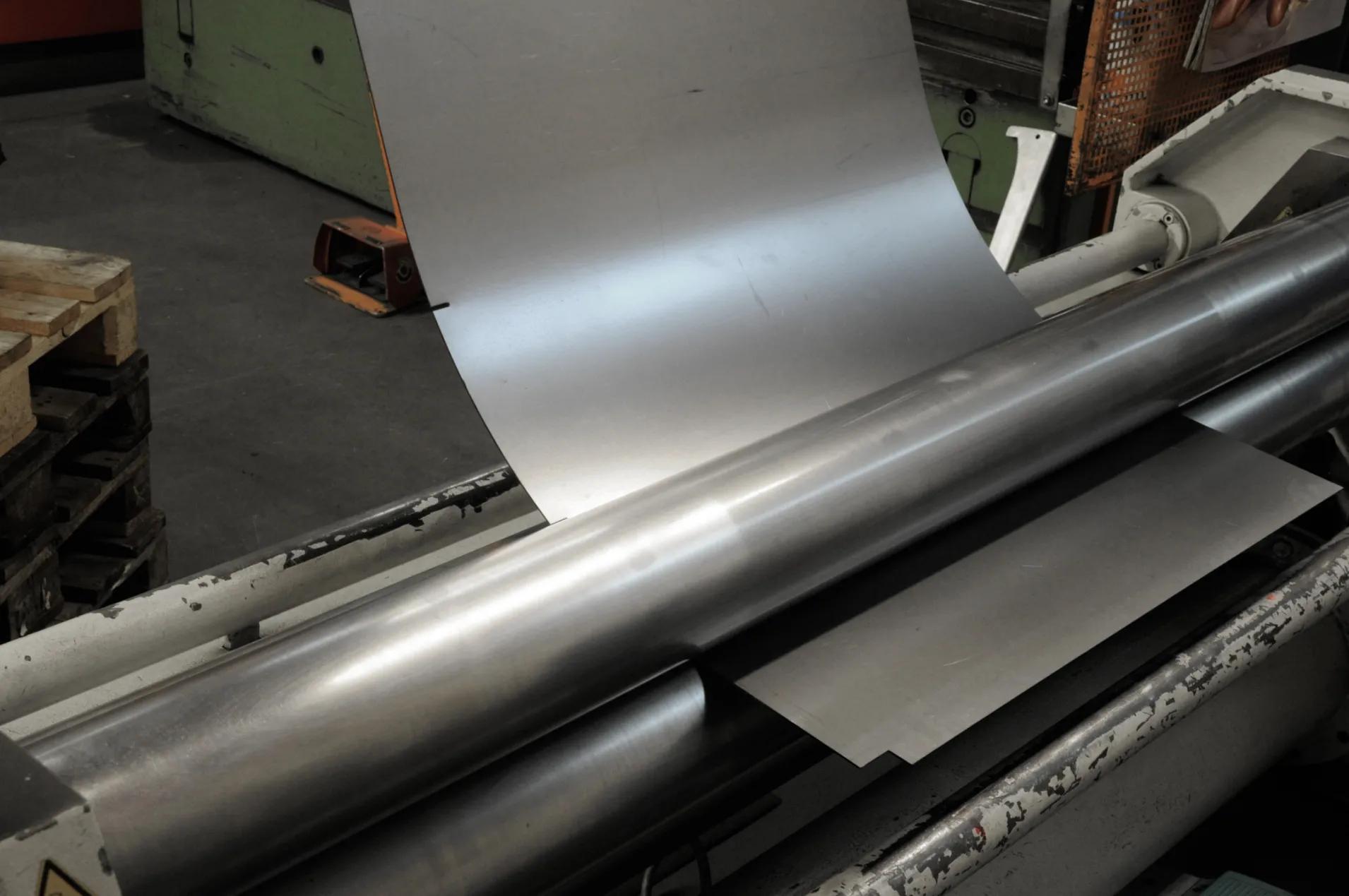

HÖRMANN Automotive produces large panel systems, fuel and hydraulic tanks, chassis, press-hardened wear and welded assemblies as well as single parts made from steel and aluminium for the agricultural machinery industry. High flexibility in production with demand- and process-oriented working stock procurement and production technology are the key to success here. The “Off-Road” business segment is characterised in general by low-volume demands and seasonal delivery orders from our customers.

All processes at HÖRMANN Automotive are focused on the products of our customers. For the projects, we implement the development, sales, project management, quality planning and advanced production planning in the product creation process in a demand-based manner. Customers can rely here on our many years of in-depth experience in the following production processes: Deep drawing, folding, 2D/3D lasering, welding, adhesive bonding and other joining methods as well as colour schemes and logistics with JIT/JIS delivery. Renowned brands such as Claas have put their trust in us and our expertise for many years.

»Our aspiration is excellence in development, production and logistics. With our many years of expertise and our passion, we design products for the agricultural machinery industry that combine all the advantages of design and function.«

Jürgen Schmidt-Nicola, Head of Off-Road Sales – Agricultural Machinery Division

Customers

References for Commercial Vehicles

Light- and heavy-duty commercial vehicles still bear the brunt of the work related to the constantly increasing freight transport in Europe and will in the future still play an indispensable role. In Europe, the commercial vehicle industry within the automotive industry is still often overshadowed by the passenger car manufacturers. However, the overall economic importance of the sector is huge and the industrial sector is already a driver of new technologies and innovations today.

The sector is faced with challenging tasks like never before: Payload optimisation, specific sector solutions, fuel efficiency, the associated target of CO2 reduction and sophisticated safety systems as well as the lowest possible emissions mean our customers are confronted with huge challenges.

What do we produce for the commercial vehicle sector?

HÖRMANN Automotive sees itself as a forming specialist and manufacturer of metallic components and systems for the commercial vehicle industry. We produce chassis parts such as longitudinal frame members and detachable frame components as well as large thin-sheet components made from steel and aluminium at our locations in Germany and Eastern Europe. We are also specialised in the forming of pipes and media-conducting lines.

The production-related specialisation in commercial vehicles allows us to drive forward innovations in a targeted manner to satisfy the growing requirements of our customers. This is achieved via further technological development in a broad partner network and also by close cooperation with our internal vehicle development. As a full-service system provider, we thus cover the entire value-added chain from development to production to logistics and service. The focus here is always on the product requirements of our customers, for whom we create individual solutions.

»A decisive change lies ahead for the commercial vehicle industry. This is why we are deliberately exploring new ways in which we can flexibly adapt our products and services to the changed requirements of our customers and the market.«

Christian Petters, Managing Director and CSO at HÖRMANN Automotive

Customers

Contact for the Press