Search

No search results

Privacy policy

Thank you for your interest in HÖRMANN Automotive GmbH. Data protection is of a particularly high priority for the company.

You can use the website without providing any personal data. If a data subject wishes to make use of our services via the website, it may be necessary to process personal data. If the processing of personal data is necessary and there is no legal basis for such processing, we always obtain the consent of the data subject.

The processing of personal data (e.g. name, address, e-mail address or telephone number of a data subject) is always carried out in accordance with the General Data Protection Regulation (GDPR) and in compliance with the country-specific data protection regulations applicable to us, in particular the Federal Data Protection Act.

With the following data protection declaration, we would like to inform the public about the type, scope and purpose of the personal data collected, used and processed by us. This privacy policy also informs data subjects about their rights.

As the controller, we have implemented numerous technical and organizational measures to ensure the most complete protection of personal data processed through the website.

Data transmissions over the Internet can, however, generally contain security gaps. It is therefore not possible to guarantee one hundred percent protection. Therefore, any data subject may, of course, also provide the company with personal data by alternative means, e.g. by telephone.

1. Definitions

This data protection declaration is based on the terms used by the European legislator for the adoption of the GDPR. The privacy policy should be both easy to read and easy to understand for everyone. To ensure this, the terms used are explained first. Among other things, these definitions are used in this privacy policy:

- "personal data" means any information relating to an identified or identifiable natural person (hereinafter "data subject"); an identifiable natural person is one who can be identified, directly or indirectly, in particular by reference to an identifier such as a name, an identification number, location data, an online identifier or to one or more factors specific to the physical, physiological, genetic, mental, economic, cultural or social identity of that natural person;

- "data subject" means any identified or identifiable natural person whose personal data are processed by the controller.

- "processing" means any operation or set of operations which is performed on personal data or on sets of personal data, whether or not by automated means, such as collection, recording, organization, structuring, storage, adaptation or alteration, retrieval, consultation, use, disclosure by transmission, dissemination or otherwise making available, alignment or combination, restriction, erasure or destruction;

- "restriction of processing" means the marking of stored personal data with the aim of limiting their processing in the future;

- "profiling" means any form of automated processing of personal data consisting of the use of personal data to evaluate certain personal aspects relating to a natural person, in particular to analyze or predict aspects concerning that natural person's performance at work, economic situation, health, personal preferences, interests, reliability, behavior, location or movements;

- "controller" means the natural or legal person, public authority, agency or other body which, alone or jointly with others, determines the purposes and means of the processing of personal data; where the purposes and means of such processing are determined by Union or Member State law, the controller or the specific criteria for its nomination may be provided for by Union or Member State law;

- "recipient" means a natural or legal person, public authority, agency or other body to whom personal data are disclosed, whether or not that person is a third party. However, public authorities which may receive personal data in the framework of a particular inquiry in accordance with Union or Member State law shall not be regarded as recipients; the processing of those data by those public authorities shall be in compliance with the applicable data protection rules according to the purposes of the processing;

- "third party" means a natural or legal person, public authority, agency or body other than the data subject, controller, processor and persons who, under the direct authority of the controller or processor, are authorized to process personal data;

- "Consent" of the data subject means any freely given, specific, informed and unambiguous indication of the data subject's wishes by which he or she, by a statement or by a clear affirmative action, signifies agreement to the processing of personal data relating to him or her.

2. name and contact details of the controller

This data protection information applies to data processing by the controller:

HÖRMANN Automotive GmbH, represented by the management: Dr.- IngMichael Radke, and this in turn represented by info@hoermann-gruppe.com or T +49 8091 56 30-0.

3. Contact details of the data protection officer:

Mr. Prof. Dr. Thorsten B. Behling

BUSE Rechtsanwälte Steuerberater

Partnerschaftsgesellschaft mbB

Berliner Allee 41

40212 Düsseldorf

T + 49 (0) 211 388 000

M +49 (0) 179 4922302

behling@buse.de

https://wwww.buse.de

Any data subject can contact the data protection officer directly at any time with any questions or suggestions regarding data protection.

4. Erasure and blocking of personal data

We process and store personal data of the data subject only for the period necessary to achieve the purpose of storage or if this is provided for by the applicable laws to which the controller is subject.

If the storage purpose no longer applies or if a legally prescribed storage period expires, the personal data is routinely blocked or erased in accordance with the statutory provisions.

5. Collection and storage of personal data and the nature and purpose of their use

a) when visiting the website

You can use this website without disclosing your identity. When you access the website, the browser used on your device automatically sends information to the website server. This information is temporarily stored in a so-called log file. The following information is collected without any action on your part and stored until it is automatically deleted:

- IP address of the requesting computer,

- date and time of access,

- name and URL of the file accessed,

- the website from which the access was made (referrer URL),

- the browser used and, if applicable, the operating system of your computer and the name of your access provider.

The company processes the aforementioned data for the following purposes:

- to ensure a smooth connection to the website,

- to ensure convenient use of the website,

- to evaluate system security and stability and

- for other administrative purposes.

The legal basis for data processing is Art. 6 para. 1 sentence 1 lit. f GDPR. The company's legitimate interest follows from the data collection purposes listed above. Under no circumstances do we use the data collected for the purpose of drawing conclusions about your person. The data will be deleted after 14 days at the latest.

We also use cookies and analysis services when you visit the website. You can find more detailed explanations on this in sections 9 and 11 of this privacy policy.

b) When using the contact form or contacting us by email

If you have any questions, we offer you the opportunity to contact the company using a form provided on the website or by email. It is necessary to provide a valid e-mail address so that we know who sent the request and can respond to it. Further information can be provided voluntarily. You are free to decide whether you wish to enter this data in the contact form or in the email.

The data entered will be processed to deal with your inquiry. The data will be deleted immediately after your request has been processed, provided there are no statutory retention periods.

The legal basis for data processing is, if the request is necessary for the performance of a contract or for pre-contractual measures, Art. 6 para. 1 sentence 1 lit. b GDPR and, in the case of statutory retention requirements, Art. 6 para. 1 sentence 1 lit. c GDPR, otherwise the legitimate interests, Art. 6 para. 1 sentence 1 lit. f GDPR. We also have a legitimate interest in processing your inquiries that are not of a pre-contractual or contractual nature in order to offer you the best possible service.

The data will be processed exclusively for the purpose of responding to your inquiry and stored for the duration of the statutory retention obligation (6 years in accordance with Section 257 (1) No. 2, (4) HGB), provided that these are commercial letters. Otherwise, the data will be deleted immediately after your request has been answered.

6. Further information on the legal basis for processing

Art. 6 I lit. a GDPR serves as the legal basis for processing operations for which consent must be obtained for a specific processing purpose. If the processing of personal data is necessary for the performance of a contract to which the data subject is party, the processing is based on Art. 6 I lit. b GDPR. The same applies to processing operations that are necessary for the performance of pre-contractual measures, for example in cases of inquiries about services and products. If we are subject to a legal obligation that requires the processing of personal data, the processing is based on Art. 6 I lit. c GDPR. In rare cases, the processing of personal data may become necessary in order to protect the vital interests of the data subject or another natural person. In this case, the processing is based on Art. 6 I lit. d GDPR. Furthermore, processing operations could be based on Art. 6 I lit. f GDPR. Processing operations that are not covered by any of the aforementioned legal bases are based on this legal basis if the processing is necessary to safeguard a legitimate interest of us or a third party, provided that the interests, fundamental rights and freedoms of the data subject do not prevail. Such processing operations are permitted in particular because they have been specifically mentioned by the European legislator (see recital 47 sentence 2 GDPR).

7. Consideration of legitimate interests

If the processing of personal data is based on Article 6 I lit. f GDPR, our legitimate interest is the performance and fulfillment of our business activities for the benefit of our employees and shareholders.

8. Use of cookies

We use cookies on the website. These are small files that your browser automatically creates and that are stored on your end device (laptop, tablet, smartphone, etc.) when you visit the company's website. Cookies do not cause any damage to your end device and do not contain any viruses, Trojans or other malware.

In the cookie, information is stored that results in each case in connection with the specific end device used. However, this does not mean that the company gains direct knowledge of your identity as a result.

The use of cookies serves on the one hand to make the use of the offer more pleasant for you. For example, we use so-called session cookies, which recognize when you have already visited individual pages of the website. They are automatically deleted after you leave the website.

In addition, we also use temporary cookies to optimize user-friendliness, which are stored on your device for a specified period of time. If you visit our website again to make use of services, it is automatically recognized that you have already been there and which entries and settings you have made so that you do not have to enter them again.

On the other hand, we use cookies to statistically record the use of the website and to evaluate this data for the purpose of optimizing the offer for you (see section 7). These cookies make it possible to automatically recognize that you have already visited the website when you visit it again. These cookies are automatically deleted after a defined period of time, at the latest after 6 months. You can also delete the cookies earlier via your browser. Please refer to the help pages of your browser.

The data processed by cookies is required for the aforementioned purposes to safeguard the legitimate interests of us and third parties in accordance with Art. 6 para. 1 sentence 1 lit. f GDPR.

Most browsers accept cookies automatically. However, you can configure your browser so that no cookies are stored on your computer or a message always appears before a new cookie is created. However, completely deactivating cookies may mean that you cannot use all the functions of the website.

9. Analysis and tracking tools

The tracking measures listed below and used by us are carried out on the basis of Art. 6 para. 1 sentence 1 lit. f GDPR. With the tracking measures used, the company wants to ensure a needs-based design and the continuous optimization of the website. On the other hand, the company uses the tracking measures to statistically record the use of the website and to evaluate it for the purpose of optimizing the offer for you. These interests are to be regarded as legitimate within the meaning of the aforementioned provision.

The respective data processing purposes and data categories can be found in the corresponding tracking tools.

10. Google Analytics

This website uses Google Analytics, a web analytics service provided by Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA ("Google"). Google Analytics uses "cookies", which are text files placed on your computer, to help the website analyze how users use the site. The information generated by the cookie about your use of this website is usually transferred to a Google server in the USA and stored there. Please note that on this website Google Analytics has been extended by the code "anonymizeIp" to ensure an anonymized collection of IP addresses (so-called IP masking). Your IP address is thus shortened within member states of the European Union or in other contracting states of the Agreement on the European Economic Area before being transmitted to the USA. Only in exceptional cases will the full IP address be transmitted to a Google server in the USA and truncated there. Google will use this information on behalf of the operator of this website for the purpose of evaluating your use of the website, compiling reports on website activity and providing other services relating to website activity and internet usage to the website operator. The IP address transmitted by your browser as part of Google Analytics will not be merged with other Google data. You may refuse the use of cookies by selecting the appropriate settings on your browser, however please note that if you do this you may not be able to use the full functionality of this website. You can also prevent the collection of data generated by the cookie and related to your use of the website (including your IP address) to Google and the processing of this data by Google by downloading and installing the browser plugin available at the following link (http://tools.google.com/dlpage/gaoptout?hl=de).

You can prevent Google Analytics from collecting data by clicking on the following link. An opt-out cookie will be set to prevent future collection of your data when you visit this website: Prohibit Google Analytics from tracking me

For more information on terms of use and data protection:

- http://www.google.com/analytics/terms/de.html

- https://www.google.com/intl/de/policies/privacy/partners/<7a>

- https://policies.google.com

The IP address and other personal data are only stored for the minimum period of 14 months stipulated by Google Analytics.

11. social media plug-ins

We use social plug-ins of social networks (e.g. Facebook, Twitter, Google+) on the website on the basis of Art. 6 para. 1 sentence 1 lit. f GDPR in order to make the company better known. The underlying advertising purpose is to be regarded as a legitimate interest within the meaning of the GDPR. Responsibility for data protection-compliant operation must be guaranteed by the respective provider. The integration of these plug-ins by the company is carried out using the so-called two-click method to protect visitors to the website in the best possible way.

a) YouTube

This website uses YouTube videos in the data protection-friendly 2-click version, i.e. personal data is only processed when you activate the plugin by clicking on it. YouTube plugins are plugins from YouTube LLC, 901 Cherry Ave, San Bruno, CA 94066, USA. YouTube LLC is a subsidiary of Google Inc, 1600 Amphitheatre Pkwy, Mountain View, CA 94043-1351, USA.

When the plugins are activated, information is sent to YouTube LLC and possibly Google Inc. in the USA. YouTube and Google are thus able to see that you have visited our site. If you are logged into your YouTube or Google account when the plugins are activated, YouTube and/or Google may be able to identify you directly.

We would like to point out that, as the provider of this website, we have no information about the data transmitted to YouTube and Google, the purposes of data collection or its use by Facebook. Further information about the data collected can be found in Google's privacy policy, which you can access at https://policies.google.com/privacy?hl=de.

We cannot provide any information about the storage period, as this is solely within the sphere of influence and responsibility of YouTube or Google.

b) Google Maps

This website has integrated a map from Google Maps to show you our locations. As soon as you access our website with the Google Maps map, a connection to Google servers is established and personal data may be transferred to Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA. If you are logged into your Google account, Google may be able to identify you directly. If you do not wish this to happen, please log out of your Google account.

You can find Google's privacy policy here: https://policies.google.com/privacy?hl=de.

12. Applications

If you apply to us via our careers page or by email, your personal data will be processed for the purpose of processing your application. The legal basis is § 26 BDSG (data processing for the purpose of the employment relationship) and Art. 6 para. 1 sentence 1 lit. f) GDPR (legitimate interest). Your data will be deleted six months after your application has been rejected. We have a legitimate interest in retaining the data for a period of six months even after your application has been rejected in order to be able to defend against claims under the General Equal Treatment Act (AGG).

13. rights of data subjects

You have the right:

- to request information about your personal data processed by us in accordance with Art. 15 GDPR. In particular, you can request information about the purposes of processing, the category of personal data, the categories of recipients to whom your data has been or will be disclosed, the planned storage period, the existence of a right to rectification, erasure, restriction of processing or objection, the existence of a right to lodge a complaint, the origin of your data if it was not collected by us, as well as the existence of automated decision-making including profiling and, if applicable. in accordance with Art. 16 GDPR, you have the right to obtain from us without undue delay the rectification of inaccurate personal data concerning you or to have incomplete personal data completed,

- in accordance with Art. 17 GDPR, to demand the erasure of your personal data stored by us, unless the processing is necessary for exercising the right of freedom of expression and information, for compliance with a legal obligation, for reasons of public interest or for the establishment, exercise or defense of legal claims,

- in accordance with Art. 18 GDPR, to demand the restriction of the processing of your personal data if the accuracy of the data is contested by you, the processing is unlawful but you oppose the erasure of the data and we no longer need the data, but you require it for the establishment, exercise or defense of legal claims or you have objected to processing pursuant to Art. 21 GDPR,

- in accordance with Art. 20 GDPR, to receive your personal data that you have provided to us in a structured, commonly used and machine-readable format or to request that it be transmitted to another controller,

- in accordance with Art. 7 para. 3 GDPR, to withdraw your consent to us at any time. As a result, we may no longer continue the data processing based on this consent in the future and

- in accordance with Art. 77 GDPR to lodge a complaint with a supervisory authority. As a rule, you can contact the supervisory authority of your usual place of residence or workplace or the registered office of one of our companies. You can find an overview of the supervisory authorities here (https://www.bfdi.bund.de/DE/Infothek/Anschriften_Links/anschriften_link…); the supervisory authority generally responsible for HÖRMANN Automotive GmbH is the

Bayerisches Landesamt für Datenschutzaufsicht

Promenade 27 (Schloss)

91522 Ansbach

T +49 98153 1300

F +49 98153 5300

poststelle@lda.bayern.de

http://www.lda.bayern.de

14. Right to object

If your personal data are processed on the basis of legitimate interests pursuant to Art. 6 para. 1 sentence 1 lit. f GDPR, you have the right to object to the processing of your personal data pursuant to Art. 21 GDPR, provided that there are reasons for this arising from your particular situation or the objection is directed against direct advertising. In the latter case, you have a general right to object, which we will implement without you having to specify a particular situation.

If you wish to exercise your right of revocation or objection, simply send an email to:

datenschutz@hoermann-gruppe.com

15. Data security

We use the widely used SSL (Secure Socket Layer) method in conjunction with the highest level of encryption supported by your browser when you visit our website. As a rule, this is 256-bit encryption. If your browser does not support 256-bit encryption, the company uses 128-bit v3 technology instead. You can tell whether an individual page of our website is transmitted in encrypted form by the closed display of the key or lock symbol in the lower status bar of your browser.

We also use suitable technical and organizational security measures to protect your data against accidental or intentional manipulation, partial or complete loss, destruction or unauthorized access by third parties. These security measures are continuously improved in line with technological developments.

16. Updating and amending this privacy policy

This privacy policy is currently valid and was last updated in April 2025.

It may become necessary to amend this privacy policy as a result of the further development of our website and offers on it or due to changes in legal or official requirements.

Legal Notice

Information as per section 5 DDG

HÖRMANN Automotive GmbH

Hauptstr. 45-47

85614 Kirchseeon

Deutschland

T +49 8091 5630-0

F +49 8091 5630-195

info@hoermann-automotive.com

Represented by the management: Dr.-Ing. Michael Radke, Christian Petters, Dr. Jürgen Lechler, Pascal Borusiak

Sole power of attorney: Johann Schmid-Davis

- Company domicile: Kirchseeon

- Registry court: Munich Local Court

- Registry number: HRB 163 762

- VAT identification number: DE 258 620 710

HÖRMANN Automotive Gustavsburg GmbH

Ginsheimer Str. 2

65462 Ginsheim-Gustavsburg

Germany

T +49 6134 588-0

F +49 6134 588-501

info.gustavsburg@hoermann-automotive.com

Represented by the management: Dr. Jürgen Lechler, Stefan Kuhn, Dr. Wolfram Schmitt, Andreas Regel, Pascal Borusiak

Chairman of the Supervisory Board: Dr.-Ing. Michael Radke

- Company domicile: Gustavsburg

- Registry court: Darmstadt Local Court

- Registry number: HRB 860 75

- VAT identification number: DE 254 992 655

HÖRMANN Automotive Saarland GmbH

Am Stahlhammer 65

66121 Saarbrücken

Germany

T +49 681 81908-0

F +49 681 81908-19

info.saarland@hoermann-automotive.com

Represented by the management: Dr. Roland Dittmann, Dipl-Ing. Martin Klein

Sole power of attorney: Jörg Straß, Jörg Moses, Rolf Klein

- Company domicile: Saarbrücken

- Registry court: Saarbrücken Local Court

- Registry number: HRB 15661

- VAT identification number: DE137 214 419

HÖRMANN Automotive Slovakia s.r.o.

Partizanska. 73

975 01 Banovce nad Bebravou

Slovakia

T +421 38 321 38 00

F +421 38 321 38 99

info.hask@hoermann-automotive.com

Represented by the management: Fabian Selder, Patrick Bräuer

Joint power of attorney: Markus Busch

entered in the commercial register of Trenčín District Court, Dept. Sro.

- IČO/commercial register number: 33553/R

- IČ DPH/VAT no.: SK 212 034 0673

- ID no.: 50 481 151

HÖRMANN Gruppe; HÖRMANN Automotive; Getty Images (für HÖRMANN Gruppe); John Deere; MAN; DAF; Atlas; Liebherr; Demag; New Holland; RSP; Wirelane; ZF Friedrichshafen

General Purchase Conditions

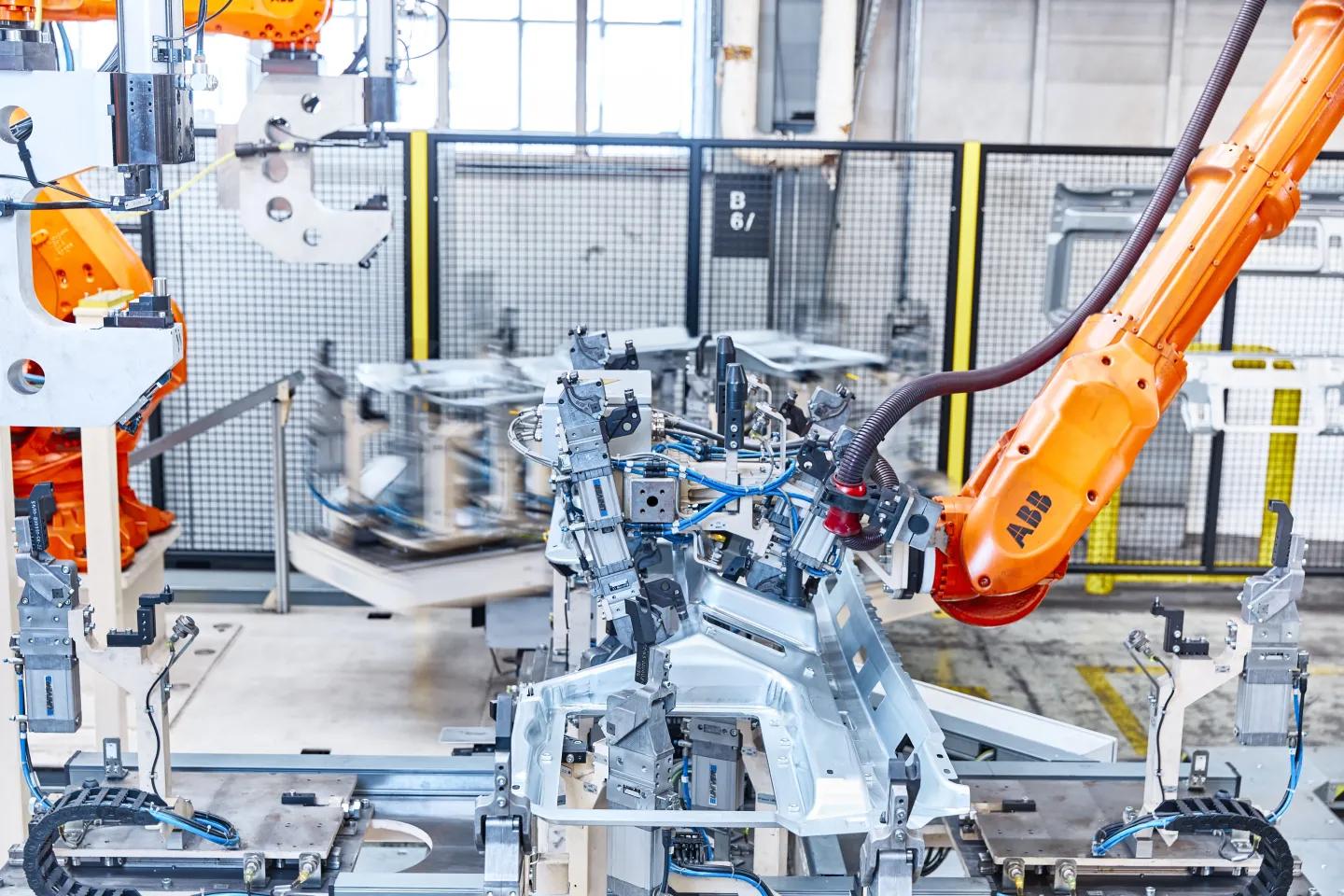

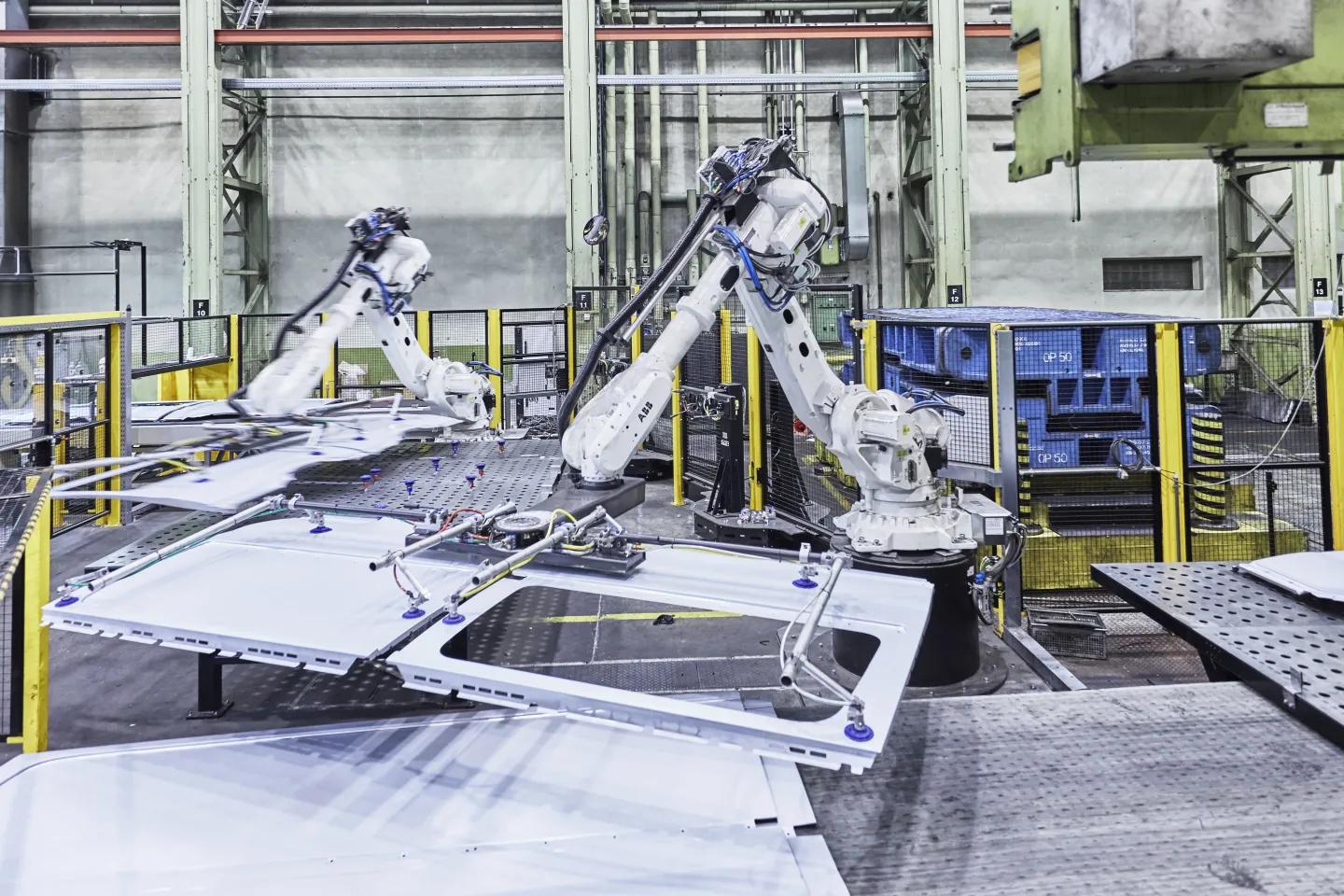

Production and Assembly

The focus of our work is always the product requirements of our customers. We take up the challenge on a daily basis to precisely identify these requirements and create ideal technological solutions.

We make your production processes leaner by means of a production- and assembly-compatible product design. During product development, we support you every step of the way – from samples up to series production maturity of your product. Our strength lies in achieving a production- and assembly-compatible design of customer-specific products and in professionally implementing the corresponding application development.

We can model the production processes in advance in 3D. In this connection, we check and optimise the error-proneness of a process already during the simultaneous product development – we thus create Poka-Yoke system solutions for the products as well as a lean and robust production process. We also have all current interfaces to the digital OEM world.

Together with you, we thus develop a concept step by step with which we continuously improve the products and processes and with which you meet the desired targets in terms of time, quality and cost. You can draw on a broad pool of services with many years of in-depth expertise: We take into account the wide variety of available production methods and realise an optimised value stream. In addition, we always include the following steps in the process chain. You benefit from a consistently lean production process that results in target-oriented resource optimisation.

We are there to lend a helping hand with our production expertise when it comes to the production-related realization of your ideas: This involves the feasibility validation, production-related product optimisation, tool design and implementation, prototyping and transfer to series production. A consistent CAE chain supports simultaneous engineering and ensures close and coordinated project execution.

Our assembly expertise ranges from assuming the overall responsibility to supply chain management to responsibility for quality control. We are happy to take over responsibility for the assembly of complex systems and modules and their demand-based delivery in the desired takt time (e.g. JIT and JIS). We thus accompany you as a partner every step of the way from the idea to production to the finished product.

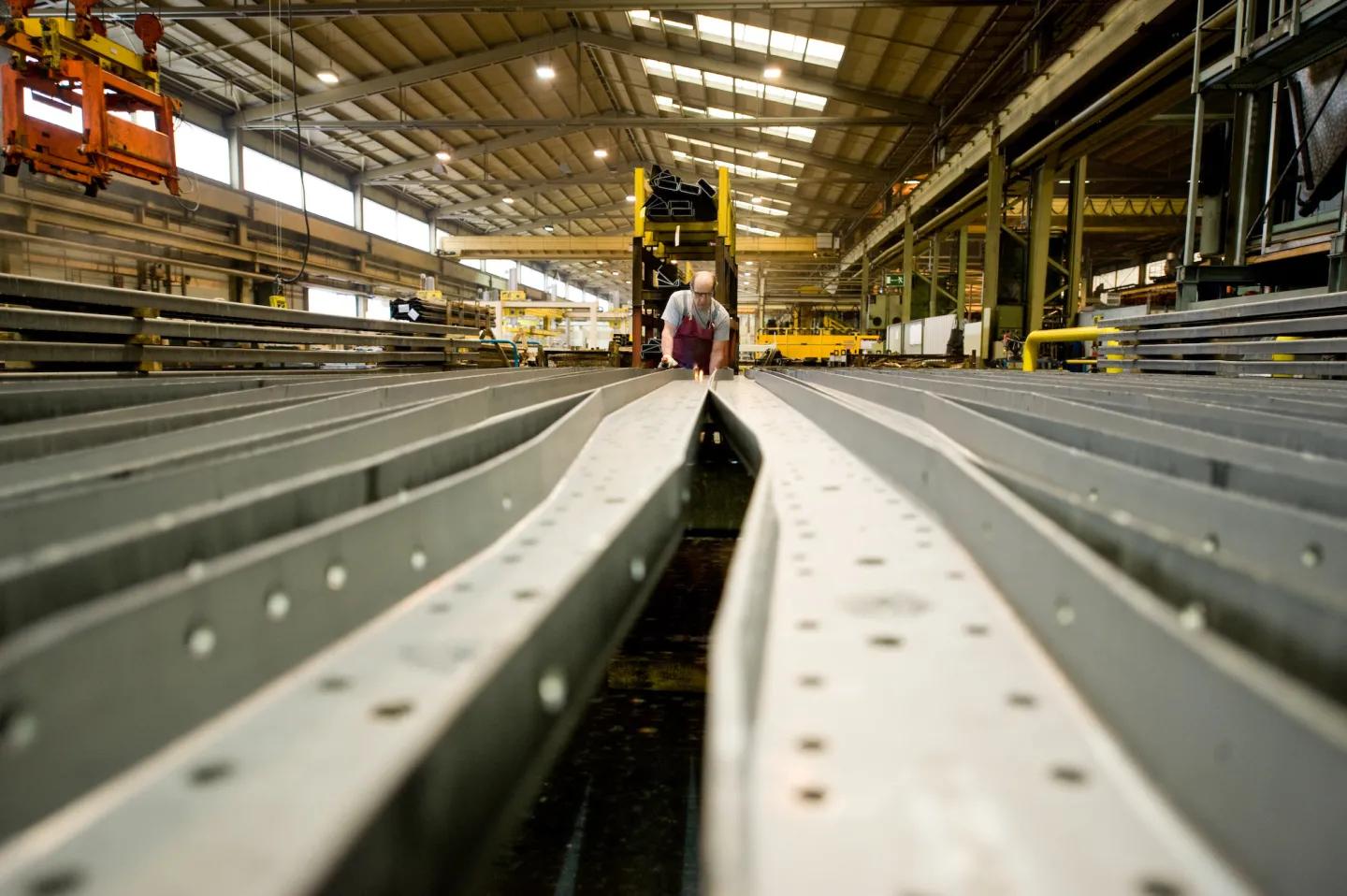

Forming

Sheet-metal working

We process fine sheets in accordance with EN 10143 and EN 10131 to a max. thickness of 3 mm, as well as thick plates with the material grade of QStE 700 TM to a max. thickness of 15 mm. Delivery takes place via truck or railway wagon, the unit weights of the coils can be up to 30 tonnes.

The systems used at our company for material preparation include the following:

- Uncoiling and cutting-to-length line up to max. 1,550 mm wide with precision straightening system, 12 m guillotine shears, magnetic lifting devices, CNC die-cutting system and roller conveyors for thick plates

- Coil line with max. blank size 2,050 x 3,700 mm for thin sheets

- Blank cutting centre with 2 lasers of 4.4 kW each, combined plasma cutting and CNC die-cutting, brushing/shot-blast systems and slitting shears

Press systems

In the Fine Sheet area, production takes place on two fully automated press lines with max. blank dimensions of 2,400 x 4,000 mm and max. 6 tools. The following are available in the Thick Plate area: Two press lines from 4,000 to 12,000 kN, one multiple-die press with 30,000 kN, a bending machine with 4,000 kN and 4,000 mm long and two presses with 50,000 kN.

Roll forming

The following systems are available in a coordinated production system for the production method known as roll forming:

- Integrated roll former with reel and straightening device

- CNC die-cutting systems

- Flame cutting robots for contour cuts

- Bending systems

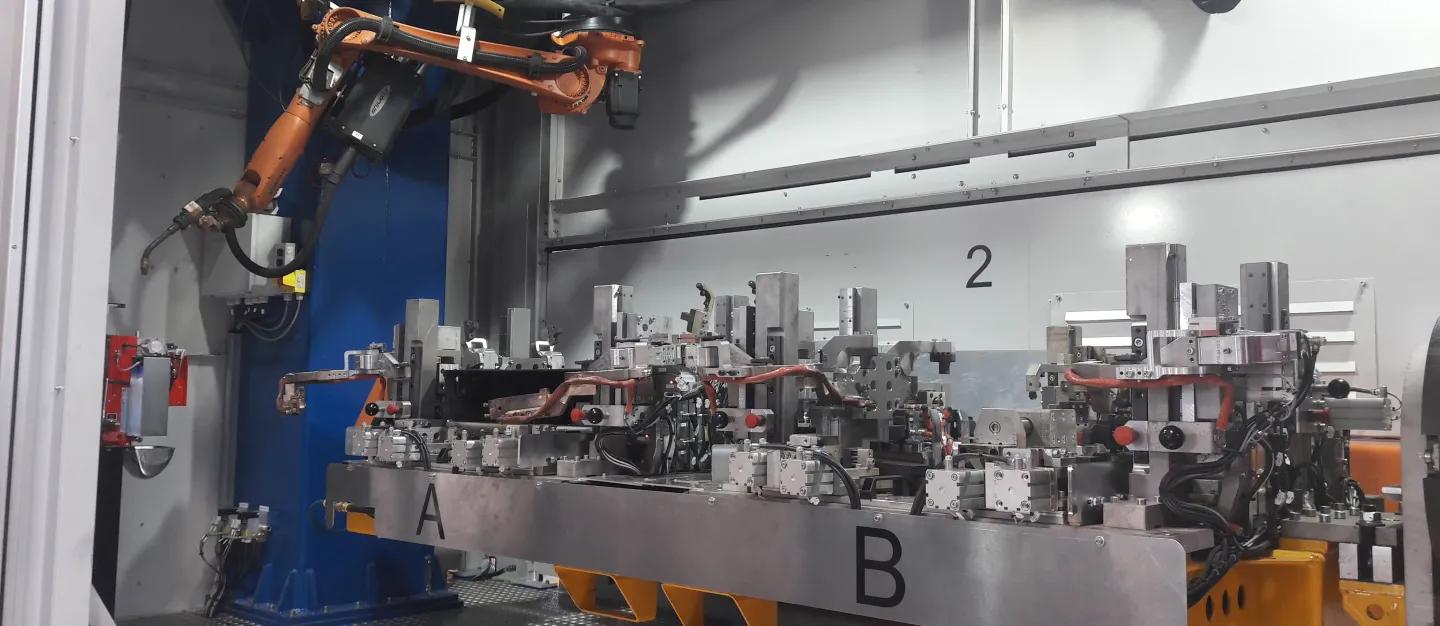

Joining

Welding

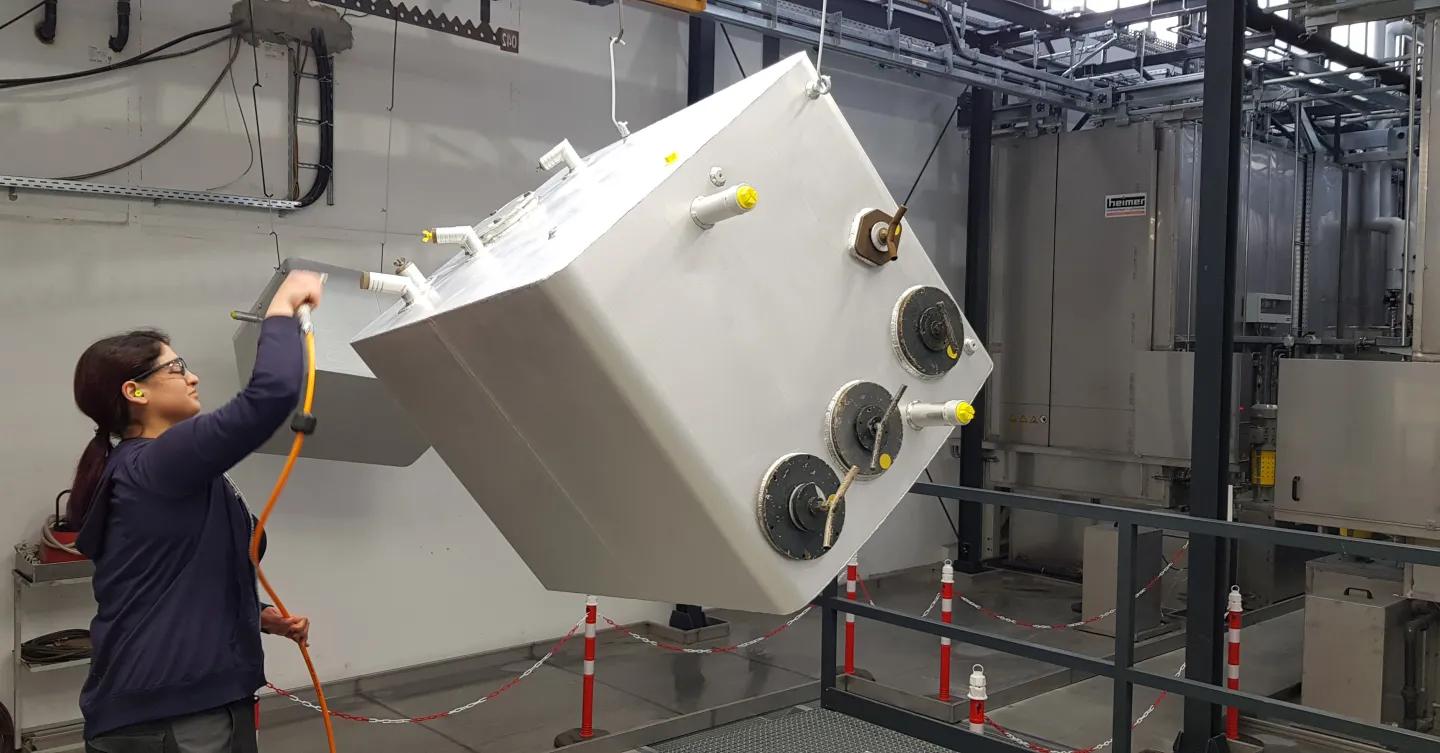

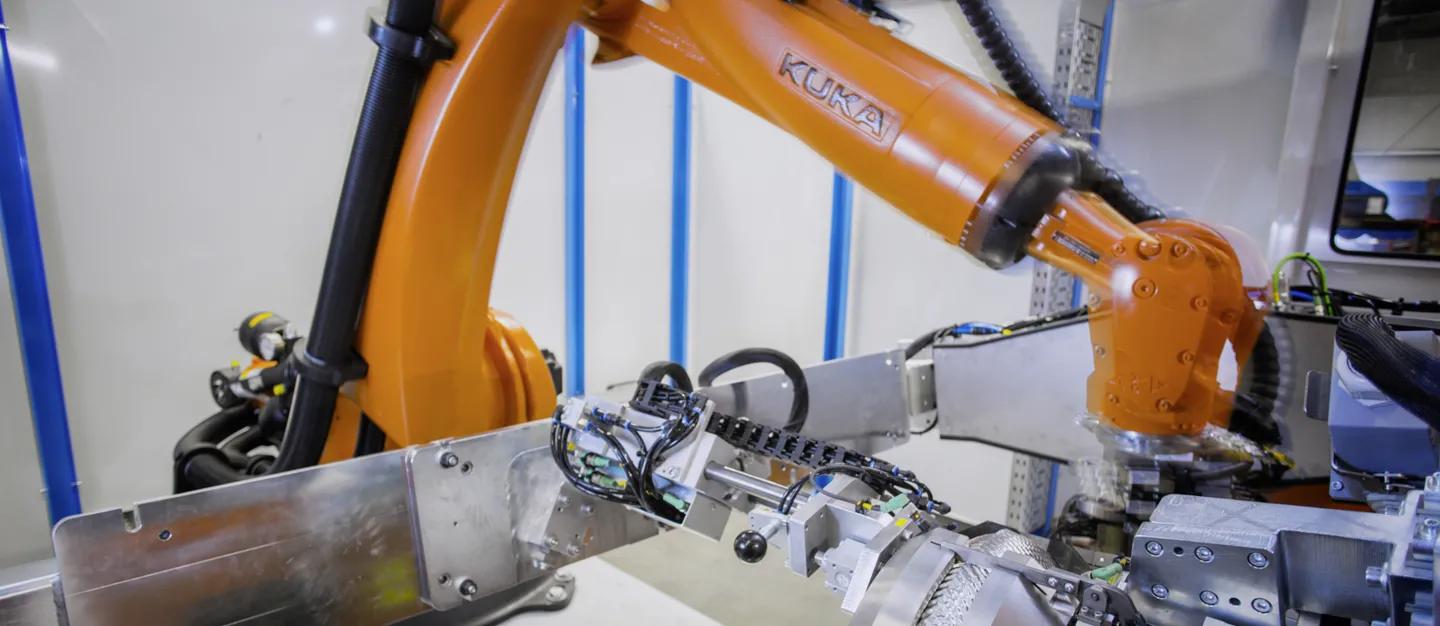

Sustainable and economic production as well as state-of-the-art design principles for safer, more comfortable and more environmentally friendly vehicles necessitate continuous innovations in welding technology. For this reason, a total of 15 state-of-the-art welding robots with rotary and tilting tables (MAG welding) are used at our locations in Gustavsburg and Banovce (Slovakia), for example. The robots are programmed in a project-related manner by our specialists. Spot-welding tongs and projection welding units with a nominal output of 400 kVA are available at table-top workstations. Workpieces with a max. length of 3,000 mm, a max. width of 1,600 mm and a max. weight of 500 kg are processed.

Adhesive bonding

The use of adhesives in current and future vehicle manufacturing is indispensable. It is the only way to join state-of-the-art structural elements to form lightweight sandwich constructions. We have the expertise and plant technology to produce sophisticated bonded joints in perfect quality.

Riveting

For positive connections with high- and ultrahigh-strength steels, we use hydraulic riveting systems for cold riveting using rivets with a diameter of 10 to 14 mm.

Welded Assemblies

The trend in recent years has shown that our customers are increasingly interested in purchasing pre-welded assemblies instead of just single parts. As a result, we deliver both manually and robot-welded assemblies, such as outer skin panels for harvesting machines or steel bumpers for trucks. Today we also already deliver the basic pressed parts for the production of cabs for harvesting machines and tractors.

Our range of services covers the following:

- Planning and industrialisation

- Prototyping

- Welding, riveting, adhesive bonding, edging

Assembly Production

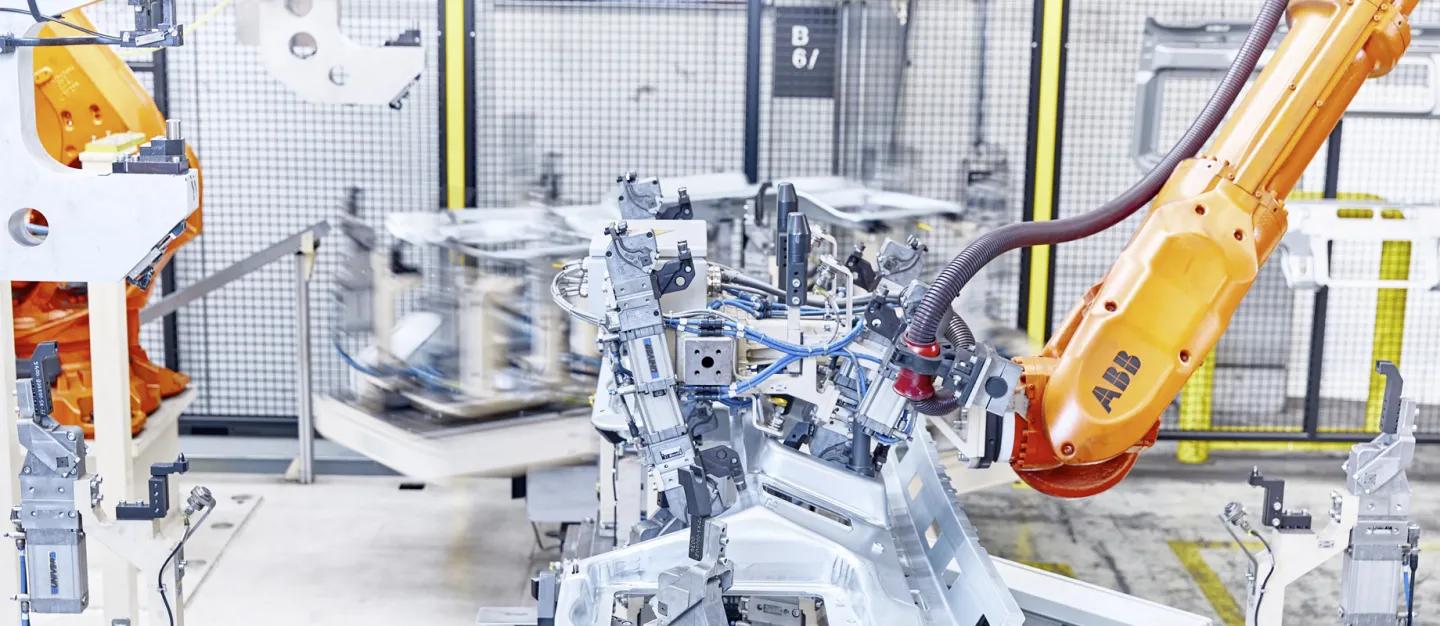

In the Assembly Production area, we cover the entire value-added chain for mechanical and mechatronic assemblies: Our services comprise all joining and machining production processes, final assembly, packaging and delivery. This also includes all upstream and downstream steps in the process chain and their control, such as procurement, MRP, control of the value chain and transport. Production is realized on largely automated and material-flow-controlled systems. Our expertise comprises all joining methods and machining such as welding, pressing, adhesive bonding, lathing, milling, screwdriving, riveting, bracketing, clipping, clinching etc. Thanks to this comprehensive technology portfolio with all established processing methods, we also meet complex requirements, such as assemblies with mechanical, electronic, pneumatic or hydraulic component parts.

3D measuring machines and optical measuring systems allow us to make high-precision measurements. In addition, we can carry out microsection investigations and microscopical analyses in our laboratory. Together with certified production processes, we thus guarantee you optimal quality results. All relevant component parts can be traced in a data-based manner. Complete documentation of the individual process steps is thus guaranteed. We take on medium to large order volumes with a series-production character and also serve niche markets with these order sizes. Each production and assembly process is set up and designed in a customised manner. Processes can be tested and modelled in advance as a 3D model. Furthermore, we have in-depth development expertise and can support you in optimising your cost structure by means of a production- and assembly-compatible product design.

Our range of services covers the following:

- Supplier selection and sourcing

- Product realisation process and project management

- Production, assembly, packaging and transport

- MRP and procurement

- Sampling

- Change management

- Complaint processing

- Supplier management and development

- Transport coordination for inbound and outbound

Coating

Cathodic dip painting

To ensure the quality and durability of our products, we have implemented customized surface technologies such as cathodic dip painting. Our systems are designed for coating complex workpieces with different layer thicknesses.

Topcoat

The topcoat film of a chassis is what gives it its colour; this coating also has weather- and chemical-resistant properties. At HÖRMANN Automotive, topcoats with liquid paint material are applied in automated application zones.

|

|

Small parts |

Long parts |

|

Max. usable size of workpiece carrier: |

W = 1,000 mm D = 1,200 mm |

L = 11,800 mm W = 400 mm D = 2,400 mm |

|

Suspension load |

Max. 400 kg per suspension |

Max. 1,600 kg per suspension |

Powder coating

As an alternative to wet painting, the more cost-effective powder coating process can also fully meet the quality requirements of our customers in many applications. Our systems preserve complex parts made of steel or aluminum automatically or manually. Whether single or multi-layer, but also in the Dublex process, customers receive first-class quality, even as contract coaters.

Max. usable size of the product carrier: L = 2,700mm x H = 2,000mm x W = 1,300mm

Max. Towing load: 500kg per trolley

Pre-Assembly

We support the continually increasing focus of our customers on their core competencies at the end of our process chain via the realisation of pre-assemblies both of individual components or modules and of complete systems, such as chassis frames for heavy-duty trucks. In this connection, we also offer consulting services and the performance of intelligent logistical processes as well as packaging and transport management in addition to pure assembly competence.

Assembly and Sequencing

Thanks to our many years of experience in the assembly and sequencing of modules and systems in the automotive sector, we are able to offer every customer a concept tailored to meet their requirements. In addition to customer-oriented process planning and the overall schedule coordination, this also includes the planning, realisation and ongoing monitoring of the entire supply chain. Our concepts range from large-volume assembly scopes with a corresponding degree of complexity and a large number of variants that we produce in a highly efficient manner with a corresponding degree of automation, to projects with low volumes that we produce in a demand-based manner in production cells with low investment requirements. Pure sequencing of component parts as what it known as a “carset” is of course also possible. Our ppm figures are the benchmark in the sector. The wide range of modules extends from pedals and pedal assemblies to cooling modules, centre consoles, roll bars to system carriers and other module scopes.

Our range of services covers the following:

- Process planning

- Investment for the required systems and tools

- Realisation in accordance with APQP and PPAP/PPF incl. sample processing

- Procurement of components (alternatively provided by customer)

- MRP for purchased parts

- Transport coordination for all incoming goods

- Assembly of offer scope

- Monitoring of supply chain, supplier management, supplier development

- Change management for components and systems

- Delivery of goods in accordance with delivery release order(s), JIS, JIT

Development Support

From the idea to series production: As a supplier to the commercial vehicle, agricultural machinery and construction machinery industries, HÖRMANN Automotive faces the daily challenge of industrialising new tools and processes for the production of its components. Efficient and targeted project management helps us to meet cost and time targets and provide our customers with the best possible support throughout the product development process. We focus on digitising the product development process as far as possible, particularly with regard to the safeguarding and optimisation of series processes. By working closely with our customers, we can use our technological expertise to help them optimise the design of components in terms of costs and technological feasibility. In doing so, we build on a broad network consisting of internal Group expertise, external service providers and universities.

We support our customers in large parts of the product development process as part of their development projects:

- Method Development

- Project Management

- Implementation of optimised technological approaches

This early involvement in the product development process offers decisive advantages: Based on our extensive technological and methodological expertise, we help our customers to optimise their component design in line with existing production restrictions. This leads to cost-optimised solutions for a given component design and reduces valuable time in the subsequent industrialisation process.

1. Method Development

Based on our technological expertise, we are able to take over the component design and development for you to meet your specific requirements. To do this, we also draw on the group-internal synergies of HÖRMANN Vehicle Engineering, which provides consistent CAE chains and expertise in the area of component design and analysis.

As part of development, we take into account production-related restrictions and potential savings or improvements in order to optimise your product and the underlying process both with regard to costs and feasibility. We can thus plan the quality you request.

2. Project Management

Based on the desired component design and the technological process design, we take over component realisation and the associated project management for you up to and including series production.

To do this, we draw on our own resources for tool design and our own toolmaker’s shops as well as on an extensive international network of service providers and toolmakers. Based on our technological and methodological expertise, we guarantee the originally planned quality.

3. Implementation of optimised technological approaches

We support you in the realisation of your products via targeted enhancement of our technologies. For this purpose, we rely on the broad range of technologies covered by our locations and on technological innovations from our advanced product development. Decisive drivers here are the processing of lightweight materials, process integration and cost effectiveness. We achieve this by working in an ecosystem consisting of suppliers and universities by means of which our technologies undergo permanent enhancement.

Innovation

Innovation goes hand in hand with customer benefit. We achieve this through close dialogue with our customers and close integration in our network of competence centres, universities and technology partners.

Our current technological focus is on the realisation of cost-efficient lightweight solutions, which are indispensable for our customers, particularly in light of the current trend towards electromobility. We are focussing on both structural and lightweight material solutions. We see both approaches as crucial in the commercial vehicle sector and are therefore intensively involved in the industrialisation of new lightweight steel construction technologies and strategies for processing promising lightweight materials.

Our claim is clear: we want to shape the mobility of the future together in a network of customers, universities and competence centres.

1. New, innovative product approaches

As an established system supplier to the commercial vehicle industry, HÖRMANN Automotive is committed to making a contribution to CO2-neutral logistics together with our customers through new ideas and approaches.

The associated challenges for the commercial vehicle industry in this context are immense and spur us on to overcome them together with our partners and customers.

Innovation for heavy-duty commercial vehicles

For HÖRMANN Automotive, the levers for innovation in heavy commercial vehicles range from economical lightweight construction approaches to functional and component integration and new topological vehicle structures.

We are also thinking in terms of completely new vehicle systems in conjunction with the semi-trailer in order to equip ourselves technologically in the best possible way for future requirements in heavy commercial vehicles.

Here, synchronous technology development in the areas of forming and joining technology provides us with significant input for the realisation of new structures and systems that differ fundamentally from today's ladder frames in terms of weight, cost, functionality and the integration of alternative energy sources.

We are guided here by customer concerns, which we see not only in terms of weight, variance and costs, but also in particular against the background of emissions legislation for the years 2025 and 2030. New solutions are needed - which is why we are already thinking them through today.

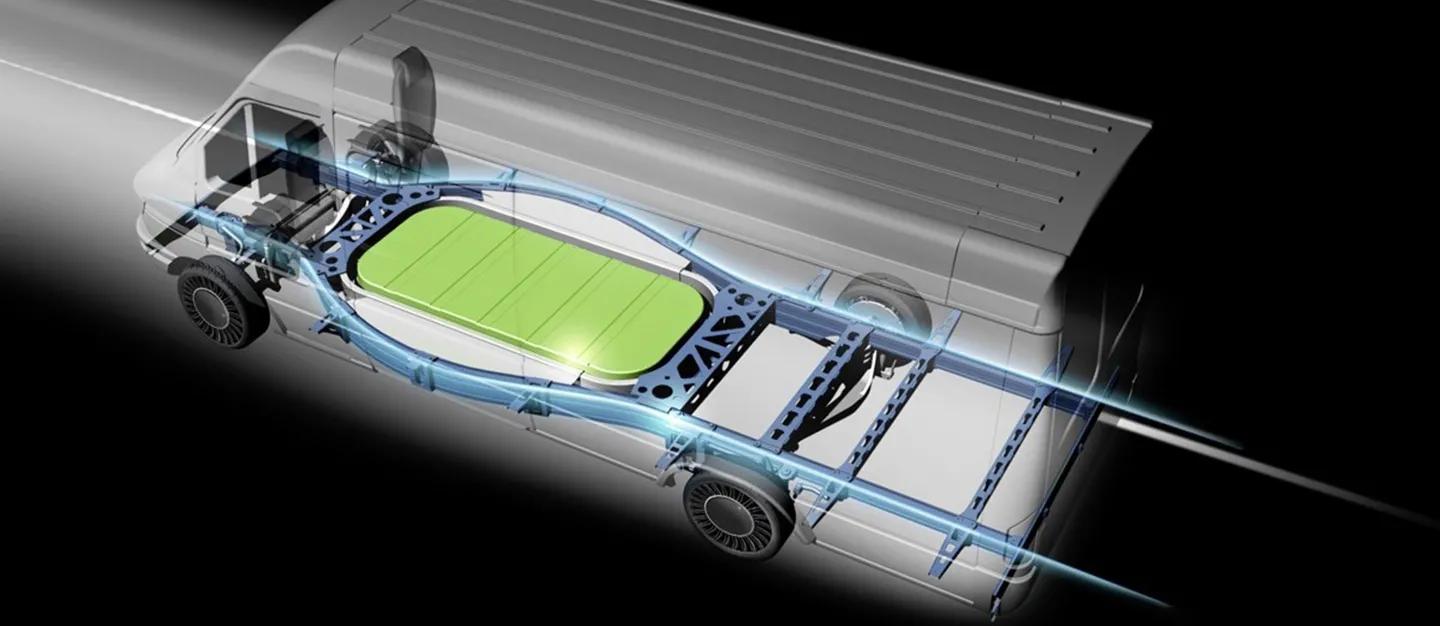

Innovation for light-duty commercial vehicles

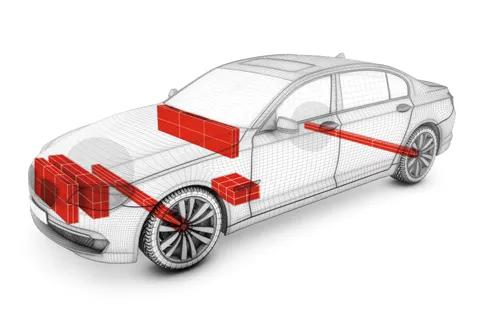

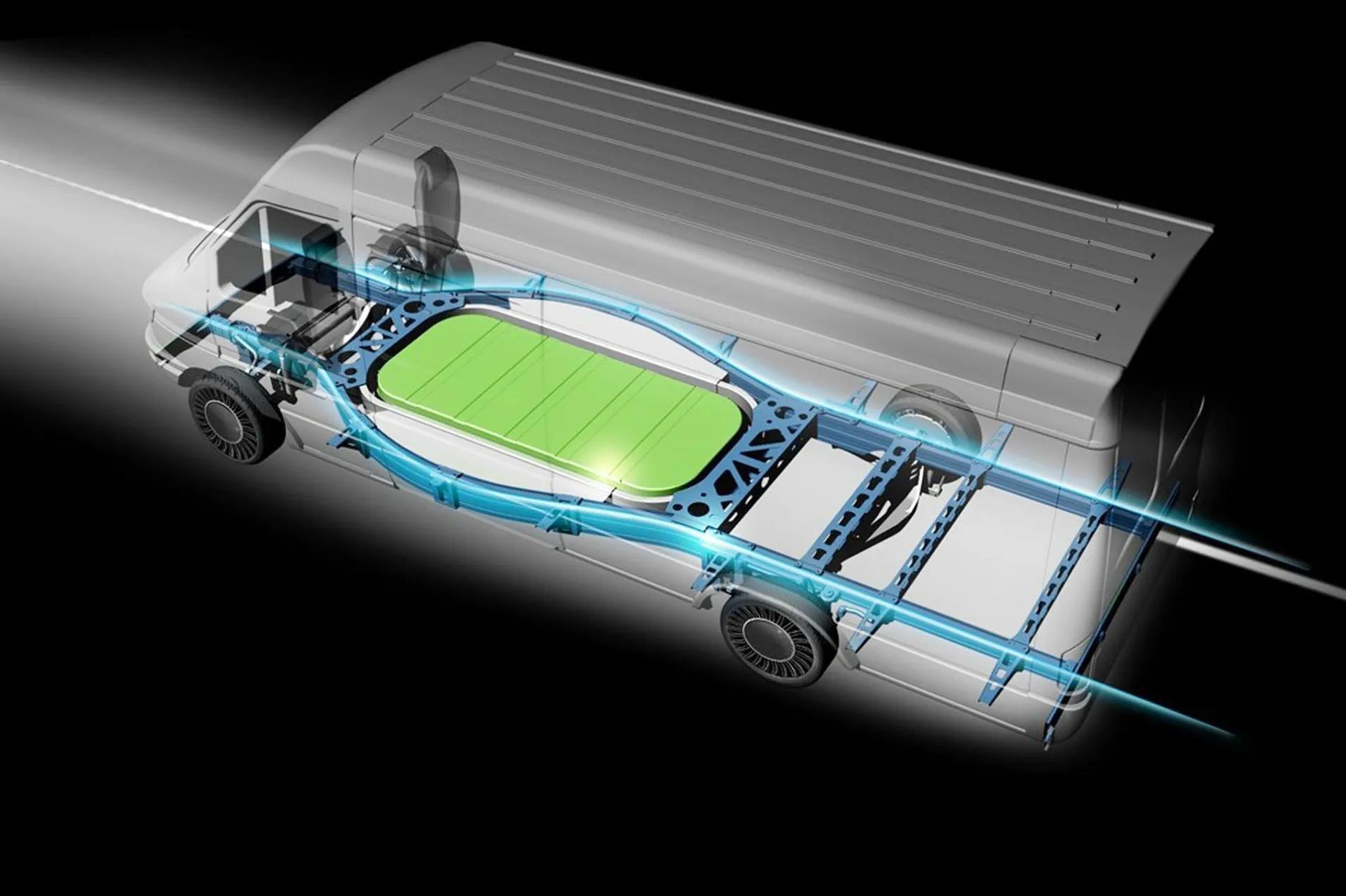

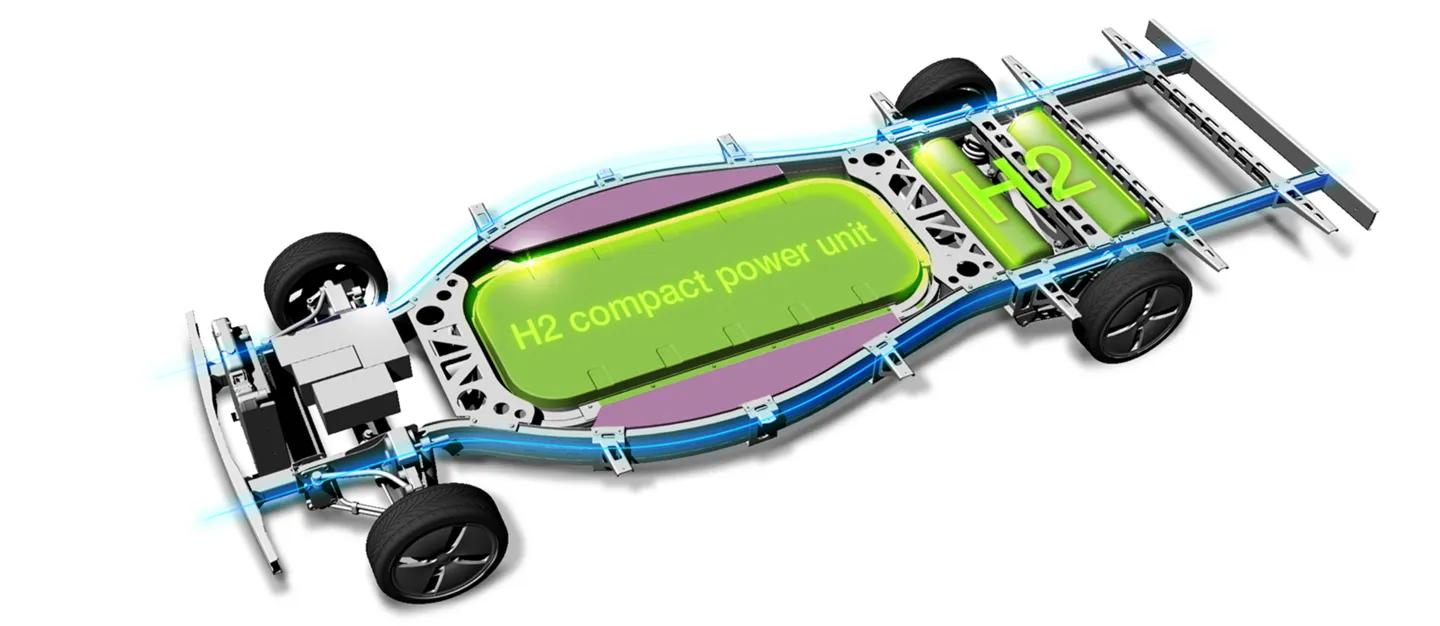

Solutions for future inner-city mobility and logistics require new, customised systems for alternative drive sources. To this end, we have developed a chassis concept for lightweight, electrified commercial vehicles.

It is characterised by a bionic lightweight construction approach, which is reflected in both the topology and the component design. The non-linear chassis topology enables systemic protection of the energy storage in the chassis and thus reduces the weight and costs of accommodating and protecting the batteries. The non-linear longitudinal members, in turn, are designed as steel multi-chamber profiles, which are specifically designed to absorb the impact energy in the event of a side crash.

> The HÖRMANN Group with innovative chassis concept at the IAA

The underlying, innovative production technology enables a high degree of variance in the profile without additional mould costs and is therefore able to cover a high degree of vehicle variance in terms of wheelbase and battery dimensions.

The vehicle study is equipped with direct wheel hub drives, which reduces the entry height and maximises the potential load volume of the body at the same time.

Innovation for railway traffic

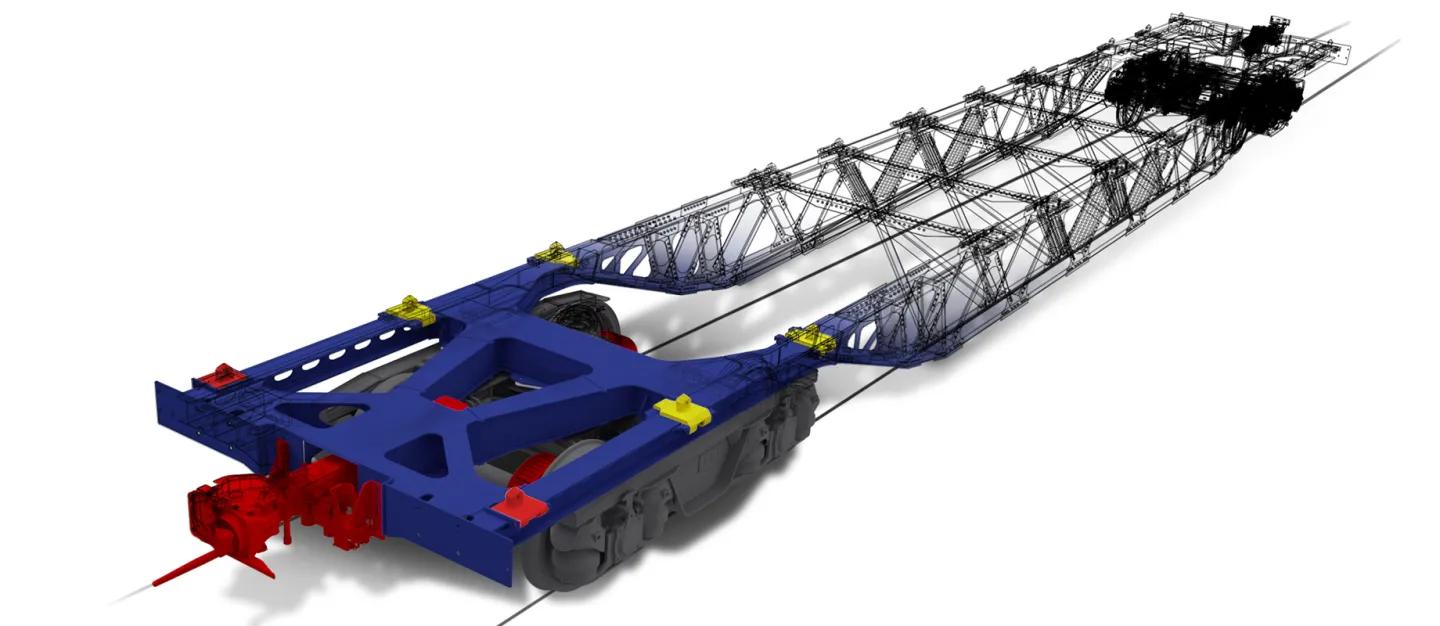

Together with HÖRMANN Vehicle Engineering, HÖRMANN Automotive is also breaking new ground in rail transport. The development of a new type of carrier wagon for rail freight transport is moving away from conventional welded assemblies and is instead based on a mechanically joined lightweight truss structure.

The carrier wagon concept addresses several customer benefits: By using highly efficient production technologies, the standardised truss elements can be manufactured cost-effectively and in short cycles. The subsequent use of mechanical joining processes reduces production costs and component distortion and also speeds up the assembly time.

At the same time, the trolley structure can be customised to different lengths and container loads - both in terms of the required lengths and the underlying loads. The result of this is a significant reduction in material usage and total weight as well as manufacturing costs.

The associated new standardised concept of the headers enables not only a reduction in weight but also the use of different coupling systems and bogies. At the same time, the end pieces can be combined with different centre segments, which increases flexibility and reduces overall costs.

Innovation for semi-trailers

Lightweight construction in semi-trailers enables increased payloads and thus increased transport efficiency. The key prerequisite for this in a highly cost-sensitive market is economical lightweight construction strategies. HÖRMANN Automotive has developed lightweight construction concepts that can make a sustainable contribution to reducing the weight of semi-trailers and form the basis for the ongoing development of an ultra-lightweight trailer concept.

The vision is to turn the semi-trailer as the actual ‘goods carrier’ into a digitalised core element of future, climate-neutral heavy goods transport.

2. Innovation in Technology Development

We support you in realising your ideas with new technological approaches. To this end, we work consistently to further develop our technologies and processes in line with the latest trends, which are currently impacting us in the form of alternative drive systems and digitalisation.

Development of lightweight technologies

The discipline of lightweight construction is experiencing a completely new relevance against the backdrop of alternative drive systems: The aim is to reduce moving masses in order to gain range and compensate for additional loads due to energy storage. We are doing this by developing new process chains for processing high-performance steel and non-ferrous materials. At the same time, we see great potential in the technological ability to create load-adaptive structures in lightweight structural engineering. Conventional forming processes often only offer the necessary degrees of freedom at considerable additional cost. With increasing flexibility of the forming process in terms of the degrees of freedom that can be achieved, we see ourselves in a position to produce load-optimised structures and to be able to realise these in high variance at attractive cost. We are currently pursuing this goal in particular with our endeavours in relation to free-form bending and gap profiling.

Integrally branched structures due to linear flow splitting

The production of integrally branched profiles offers innovative solutions in terms of component connection and the utilisation of integrally branched multi-chamber profiles. In this process, a flat sheet is formed into a double-T profile as part of a continuous rolling process by moulding rollers on both strip edges, which offers new design options in terms of lightweight construction and functional integration. At the same time, it is possible to produce non-linear profiles by integrating a bending process into the production line. This means that the ‘gap profiling’ mass production process can also offer significant added value in applications with high variance. This has been proven in the context of the bionically orientated vehicle topology of the Hörmann integral chassis, which can be produced with minimal tool investment thanks to the process chain described, even with high variance - particularly in terms of wheelbase and chassis dimensions.

Free-form bending

The stringent continuation of the technological focus of tube bending at HÖRMANN Automotive is free-form bending. Extensive geometric design freedom in the profile without additional tool costs enables the cost-attractive production of innovative, topographically optimised structures. We work closely with system manufacturers and universities in the ECO system to further develop free-form bending against the background of batch- and geometry-related component tolerances through adapted control and regulation mechanisms.

Development of process chains for the production of hybrid composites

In many cases, multi-material systems offer added value, particularly in the area of large-scale component applications in the agricultural machinery sector, which are both weight and wear-sensitive and also have to fulfil additional functions due to the attachment of a wide variety of add-on parts. We take this trend into account and are involved in the development of metal-plastic composites with a focus on optimising the use of materials and intelligent options for process integration while maintaining component performance.

Digitalisation in forming Technology

Smart tools

New approaches to tool digitalisation allow us to track component quality where it is created: in the tool. The integration of sensory elements in tool systems allows us to have a transparent view of the forming process for the first time and thus enables us to develop technological processes based on cause-and-effect chains within the tool.

HÖRMANN Automotive Slovakia s.r.o

HÖRMANN Automotive Slovakia GmbH is your ideal partner for the production of high-quality, cost-optimised components and systems made from metal.

Components and systems made from metal

We currently produce approximately 1,300 different products and deliver on a daily basis around 30,000 components to our customers. In three-shift operation, we process approximately 40 tonnes of single rolled and coil sheets in different thicknesses, formats and widths every day.

State-of-the art technology in laser systems, folding presses, robot welding systems and above all our approximately 300 employees have made us a sought-after partner for the vehicle industry.

Every day, we utilise all our experience and expertise to fulfil the requirements of our customers with regard to flexibility, quality, reliability and economic efficiency without compromise.

HÖRMANN Automotive Slovakia s.r.o

Partizanska. 73

95701 Banovce nad Bebravou

Slowakei

Your Contact

Thank you for your Message

We will contact you shortly.

Contact

We are always here for you – give us a call or send us a message. We are happy to call back!

HÖRMANN Automotive GmbH

Hauptstraße 45-47

D-85614 Kirchseeon

T +49 8091 5630-0

F +49 8091 5630-195