References for E-Mobility

The electrification of the drive world is continuing unabated – whether as hybrid or fully electric. The electric drive is no longer just for passenger car traffic: Hybrid and electric buses also are winning over admirers with less noise and lower consumption. Commercial vehicles can thus drive into city centres in spite of environmental zones and night-time noise restrictions.

HÖRMANN Automotive sees itself as a competent supplier and contact for the following topics:

- Charging infrastructure

- Micromobility

- Innovative battery carrier concepts

To be able to support the trend topic of “e-mobility” to the maximum, the infrastructure is key as the system can only function with this. HÖRMANN Automotive is positioning itself as a neutral industrialiser and assembly service provider for charging stations, for example. The plant in Wackersdorf current offers the D Module (production quality assurance certificate).

The discussions about climate protection and the change in the automotive sector are also resulting in new players in the market. HÖRMANN Automotive defines micromobility as small electric vehicles for urban life and the last mile. In this connection, new automotive OEMs and products such as the e-scooter are appearing on the market. HÖRMANN Automotive is also present here as a neutral industrialiser & assembly service provider. The plant in Wackersdorf is using its experience of recent years here and is implementing quality standards for the customers.

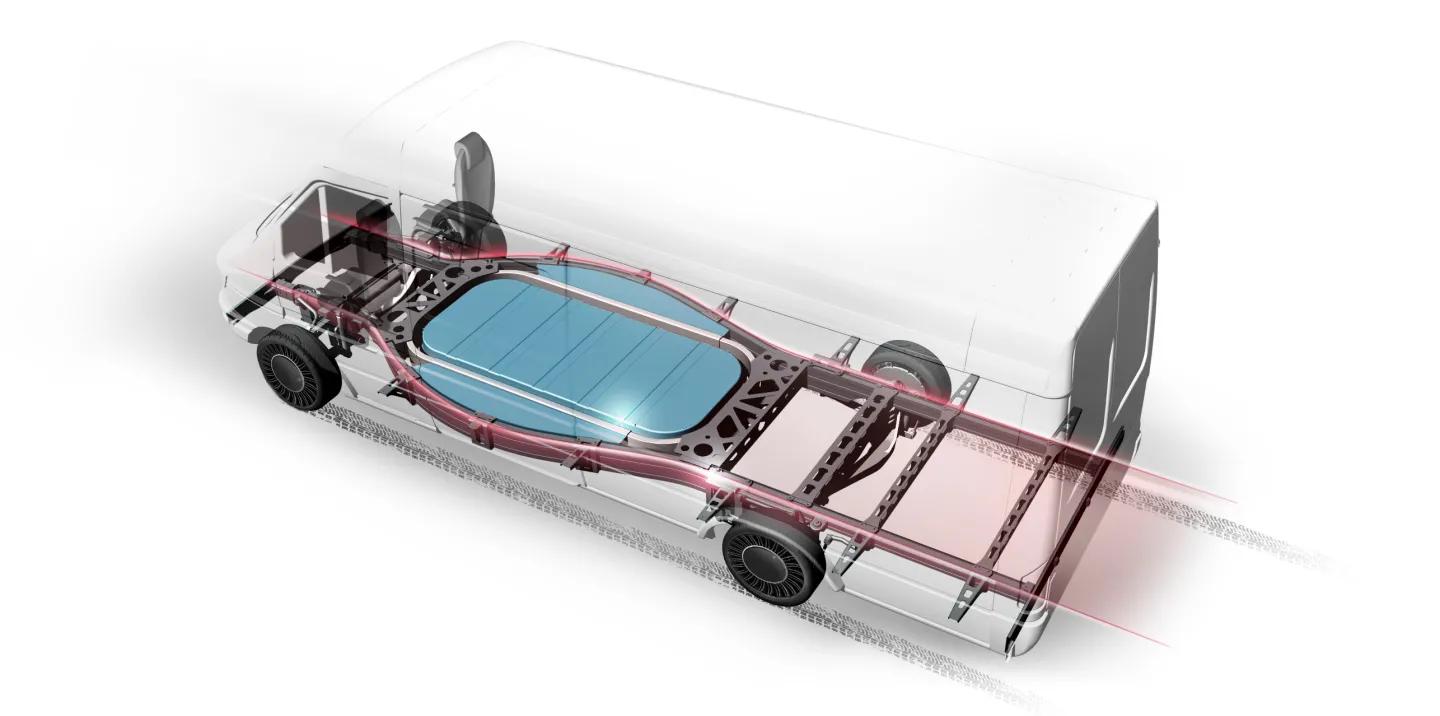

Our focus lies in particular on the innovative battery concepts. The chassis for light commercial vehicles (LCV) in the “Last Mile” area of HÖRMANN Automotive is characterised by a bionic lightweight design approach that can be seen both in the topology and in the component design. The non-linear chassis topology facilitates systemic protection of the energy storage units in the chassis and thus reduces the weight and costs for the accommodation and protection of the batteries. The non-linear longitudinal members are made in turn from steel multi-chamber profiles that are designed specifically for the absorption of impact energy in the case of a side crash. The underlying, innovative production technology allows a high number of variants in the profile configuration without additional tooling costs and is thus able to cover a high number of vehicle variants with regard to the wheelbase and battery dimensions. The vehicle is equipped with wheel hub direct drives and thus has a reduced entrance height and at the same time maximises the potential loading volume of the body.

In this connection, HÖRMANN Automotive sees itself as a system partner of customers – from the development to the production of innovative thick plate concepts, welded components, fine sheets for body parts to the assembly of mechanical and mechatronic assemblies. We orientate all processes to customer requests and adapt them accordingly. Thanks to the cooperation in what are known as ecosystems with established system suppliers as well as start-ups, highly innovative solutions are developed for the electromobility of the future.

Customers