From the idea up to series production

HÖRMANN Automotive ist in verschiedenen Branchen der Nutzfahrzeugindustrie unterwegs und verfügt über vielfältige Referenzen.

Referenzen

Rahmenlängsträger und Rahmenanbauteile für Truck

Rahmenlängsträger und Rahmenanbauteile für Truck

Hydrauliktanks für Baumaschinen

Kabinenteile für Traktoren

Medienführende Leitungen für Traktoren

Komponenten für Ladesäulen

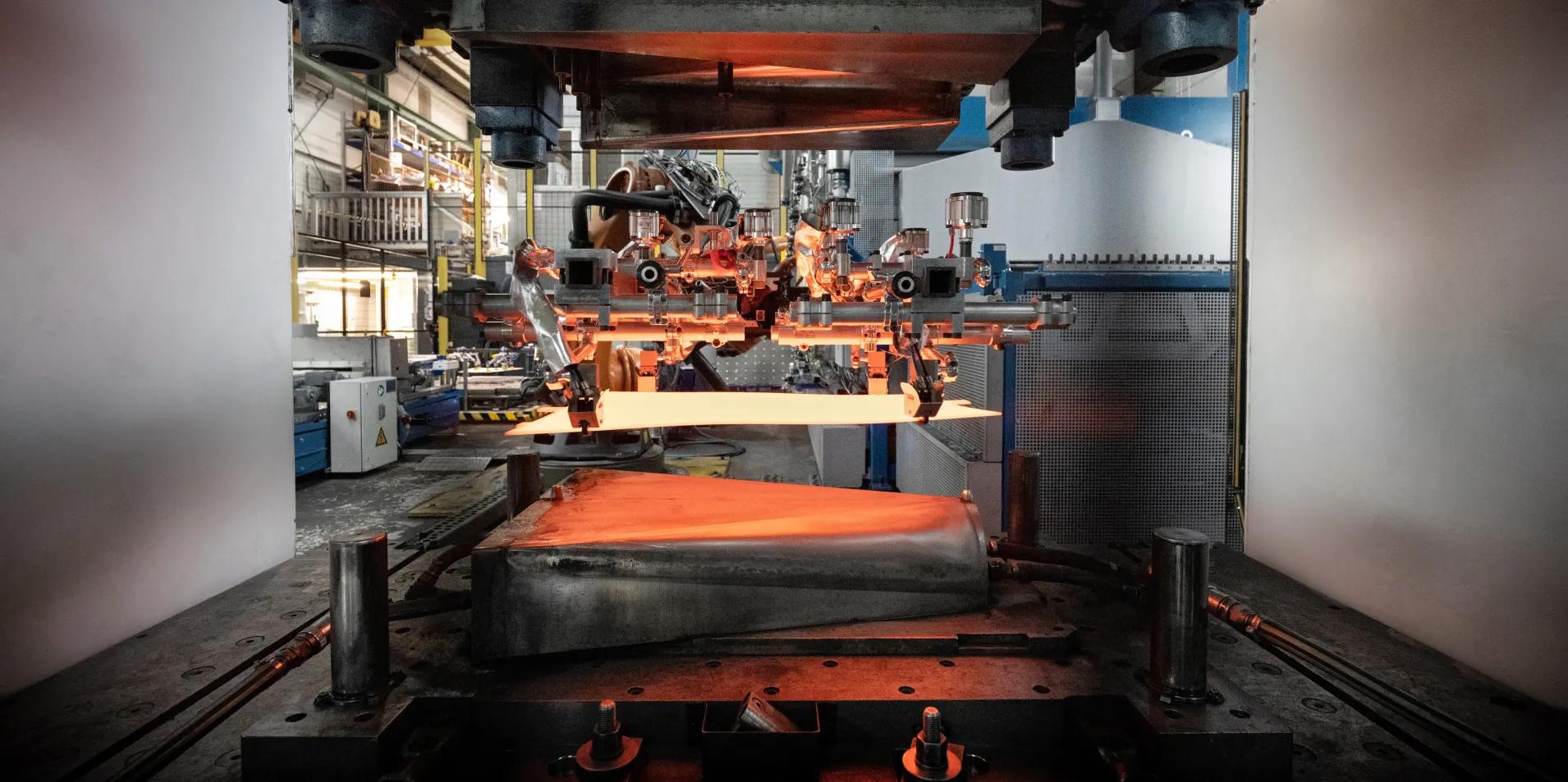

Entwicklung, Betriebsmittelbau und Fertigung Rahmenlängsträger und Rahmenanbauteile sowie großflächige Feinblechkomponenten aus Stahl und Aluminium für MAN

Entwicklung, Betriebsmittelbau und Fertigung Rahmenlängsträger und Rahmenanbauteile sowie großflächige Feinblechkomponenten aus Stahl und Aluminium für DAF

Entwicklung, Betriebsmittelbau und Fertigung von Hydrauliktanks bis 1.600 Liter für Liebherr

Entwicklung, Betriebsmittelbau und Fertigung umgeformter, gelaserter, montierter und lackierter Klappensysteme für Claas JAGUAR

Entwicklung, Betriebsmittelbau und Fertigung umgeformter und gelaserter Serienbauteile für die 5R-Traktor-Serie von John Deere

Entwicklung und Fertigung von Komponenten für Ladesäulen von Wirelane

Produkte

Chassis

Body-in-White

Seitenverkleidungssysteme

Busdecken

Kraftstoff- und Hydraulik-Behälter

Schweißsysteme

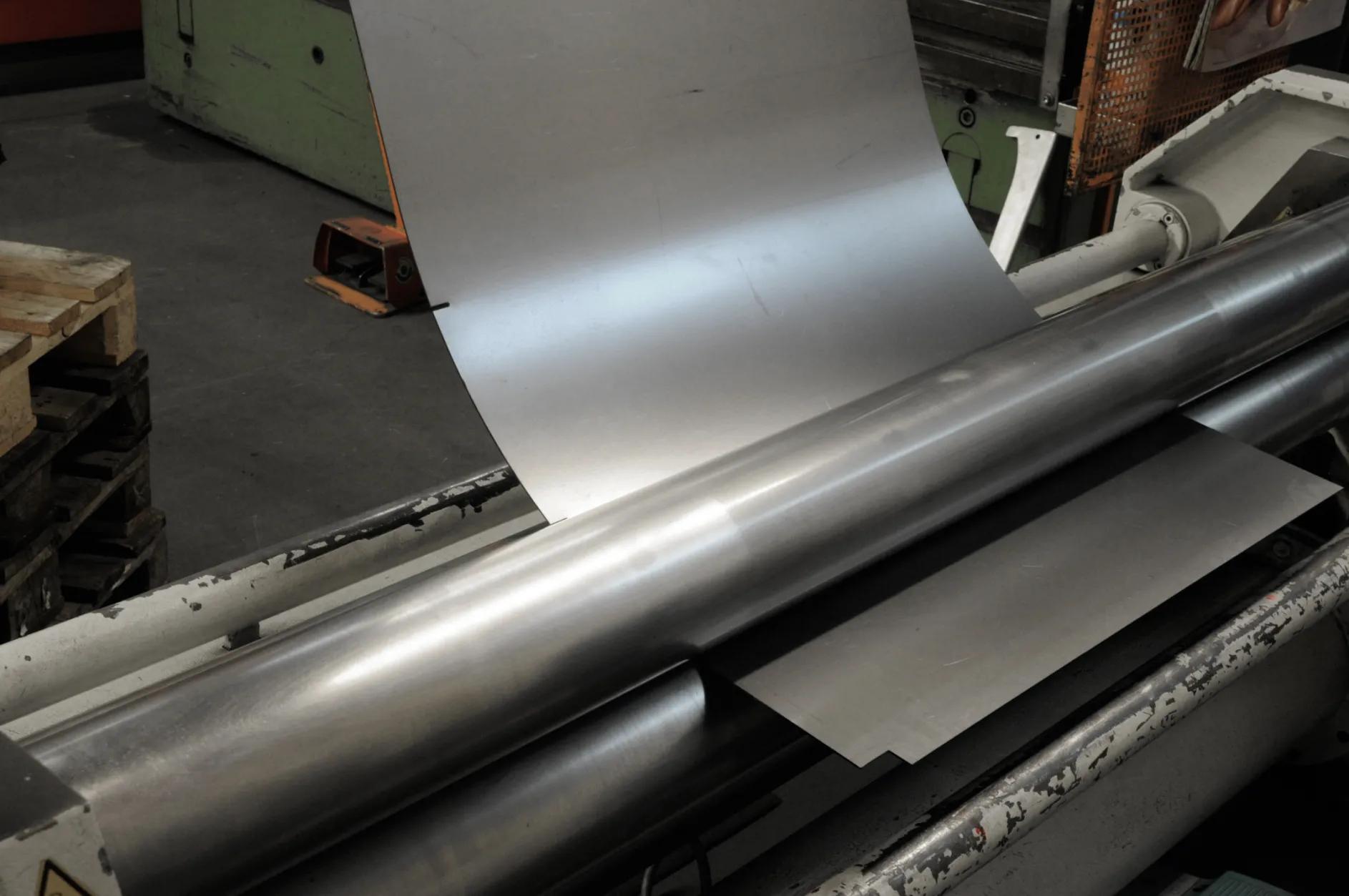

Pressteile

Kraftstoff-und Kältemittel-Rohre

Aluverkleidungen und -klappen

Schweißkomponenten

Verpackung von Komponenten

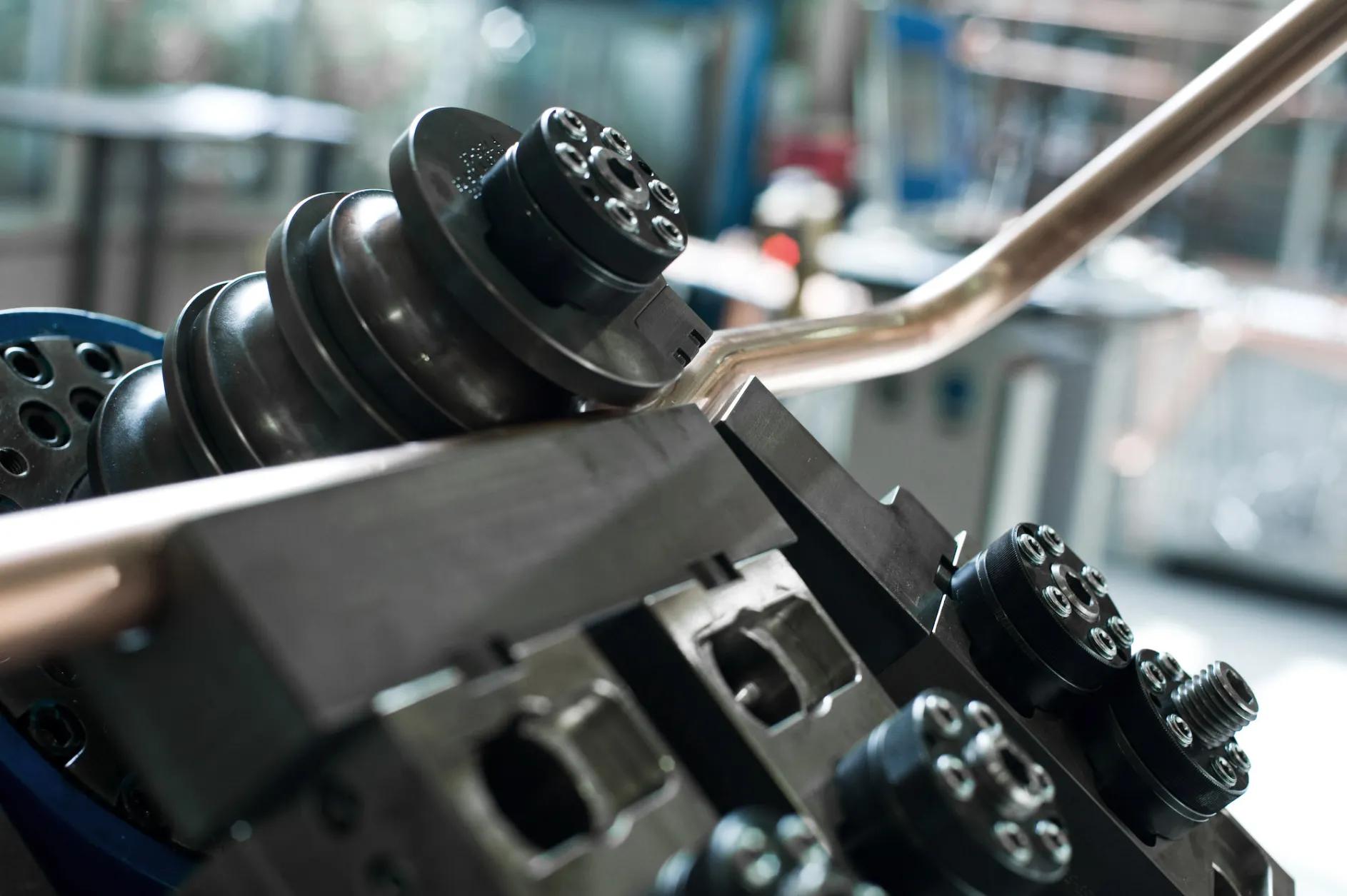

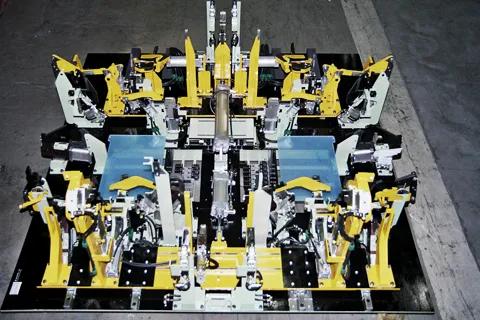

Vorrichtungsbau

Wir bieten Fahrzeug-Chassisteile, Fahrzeug-Anbauteile, Oberflächentechnologien, produktionsspezifische Schnitt-, Biege- und Ziehwerkzeuge, Rahmen-Vormontage, Just-In-Sequence- und Modulbelieferungen.

Wir liefern alles, was die Karosserie-Außenhaut eines Automobils ausmacht.

Wir liefern lackierte und vormontierte Seitenverkleidungsteilen für Erntemaschinen, die "just-in-time" an das Hauptmontageband geliefert werden.

Produktion und einbaufertige Montage von Innenausstattungssystemen für Nutzfahrzeuge, insbesondere von Deckensystemen

Wir besitzen jahrzehntelange Erfahrung in der Herstellung von Kraftstoff- und Hydrauliktanks.

Wir fertigen komplette Fahrgestelle für Düngemittelfahrzeuge und neuerdings auch für einen Feldhäcksler.

Nach dem Bedarf unserer Kunden, die vorwiegend aus der Land- und Baumaschinentechnik kommen, konzipieren wir Produkte für ganz spezielle Anforderungen.

In der Fertigung von einbaufertigen Rohrsystemen für den Transport von Kraftstoffen und Kältemitteln in Bussen und PKW besitzen wir ein in jahrzehntelanger Tätigkeit erworbenes Fertigungswissen.

Die Fertigung von Kofferraum- und Tankklappen sowie Verkleidungen aus Aluminium für Busse und Nutzfahrzeuge gehört neben den Tanks zu unseren Kernkompetenzen.

Wir fertigen vorwiegend achstragende Fahrwerkteile verschiedener Komplexitätsgrade, die wir – zu Schweißbaugruppen und -komponenten montiert – direkt ans Band liefern.

Wir übernehmen die Gesamtverantwortung für die Verpackung und Lieferung von Ersatzteilen, CKD-Komponenten und Kit-Lösungen.

Wir planen und fertigen innovative Vorrichtungen, mit deren Hilfe die verschiedenen Einzelteile eines Endproduktes oder komplexerer Komponenten maßhaltig miteinander verschweißt werden können.

Arbeiten bei einer dynamischen Unternehmensgruppe

Wir sind ein attraktiver Arbeitgeber für engagierte und leistungsorientierte Mitarbeiter.