HÖRMANN Automotive Saarland GmbH

Specializing in cold and hot forming, welded assemblies, piping, and interior systems

HÖRMANN Automotive Saarland GmbH specializes in the development and manufacture of high-quality cold and hot forming components, welded assemblies, piping, and ready-to-install interior systems. With over 35,000 square meters of production space and around 350 skilled employees, we serve customers in the agricultural and construction machinery industry as well as the industrial truck, commercial vehicle, and bus sectors.

Our portfolio is divided into the following three areas:

- Bodywork

The bodywork division covers structural and outer skin parts, such as side and tail doors for combine harvesters, body parts for tractors, industrial trucks, and commercial vehicles, as well as outer skin parts for camper vans and trucks. - Chassis & components

In the chassis and components sector, the company produces complex welded assemblies such as discharge manifolds for harvesters, bumpers for trucks, and large main frames up to 6.5 meters in length for forage harvesters and sprayers. It also manufactures heavy-duty components for agricultural machinery, which are particularly resistant thanks to the press hardening process. - Interior systems

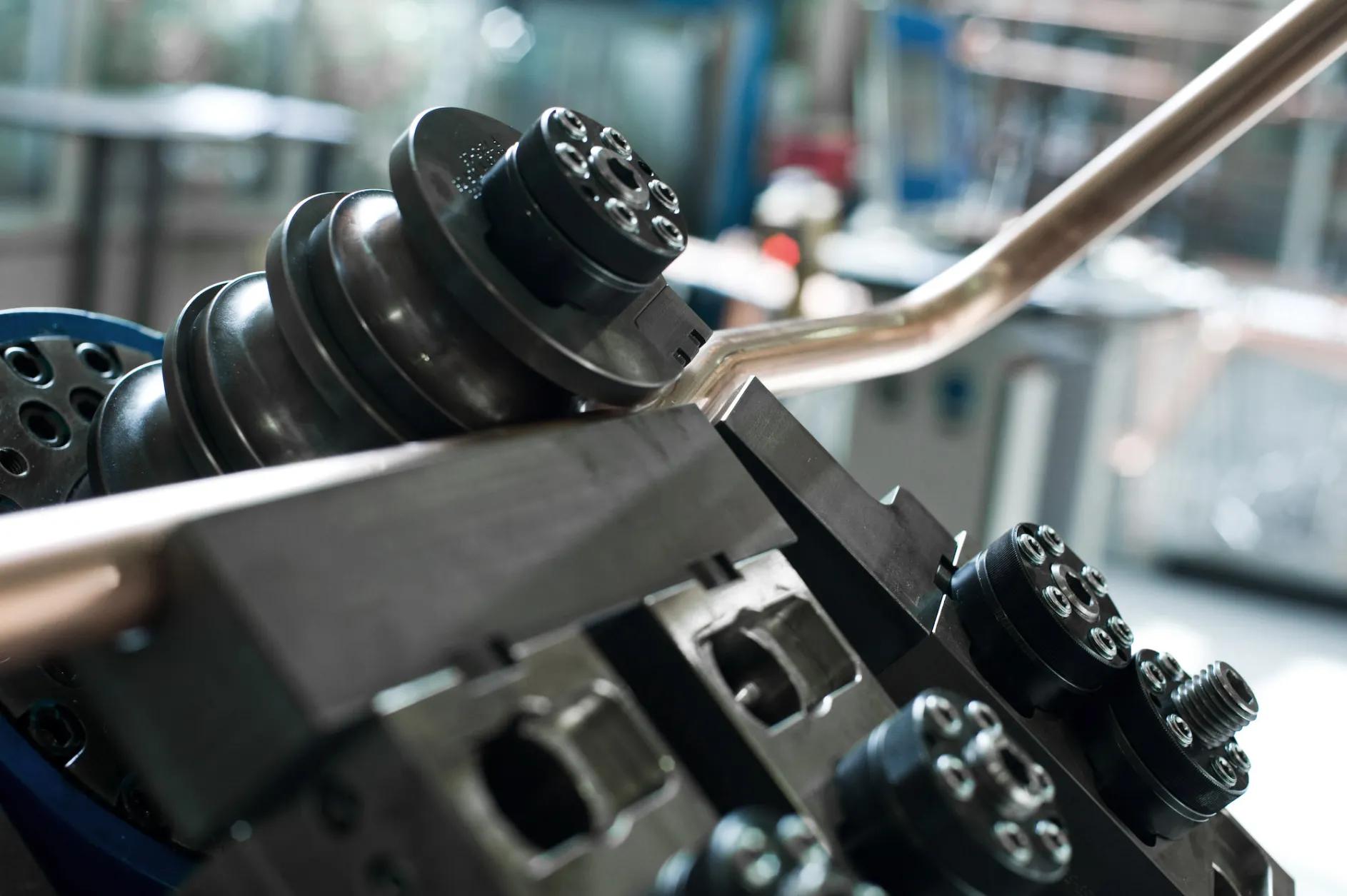

The interior division specializes in the production of ready-to-install ceiling systems, air conditioning ducts, and aluminum profiles for city buses and coaches. This division also manufactures pipes for operating fluids such as refrigerants, hydraulic fluids, and fuels.

Our core competencies at a glance

Development, mechanics, and toolmaking

Our experts in design and component development have extensive experience in sheet metal forming, welding technology, and fixture construction. Using state-of-the-art CAD software such as CATIA and PAM-STAMP, we create innovative designs and carry out comprehensive feasibility studies and dynamic stress analyses. Close cooperation between our specialist mechanics and toolmakers enables the precise manufacture of complex forming tools, welding and assembly fixtures, and the development of prototype tools using sophisticated CNC machining techniques.

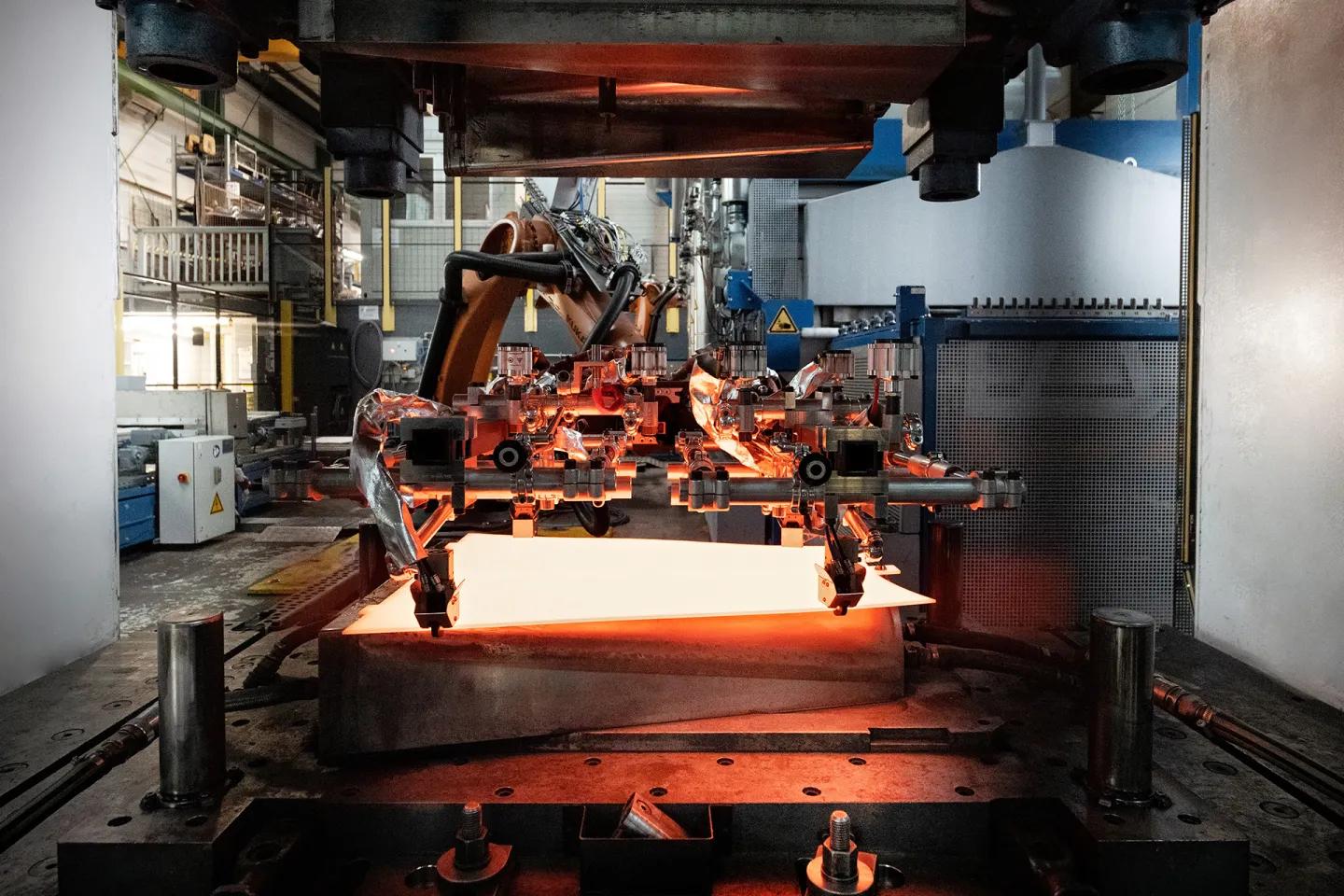

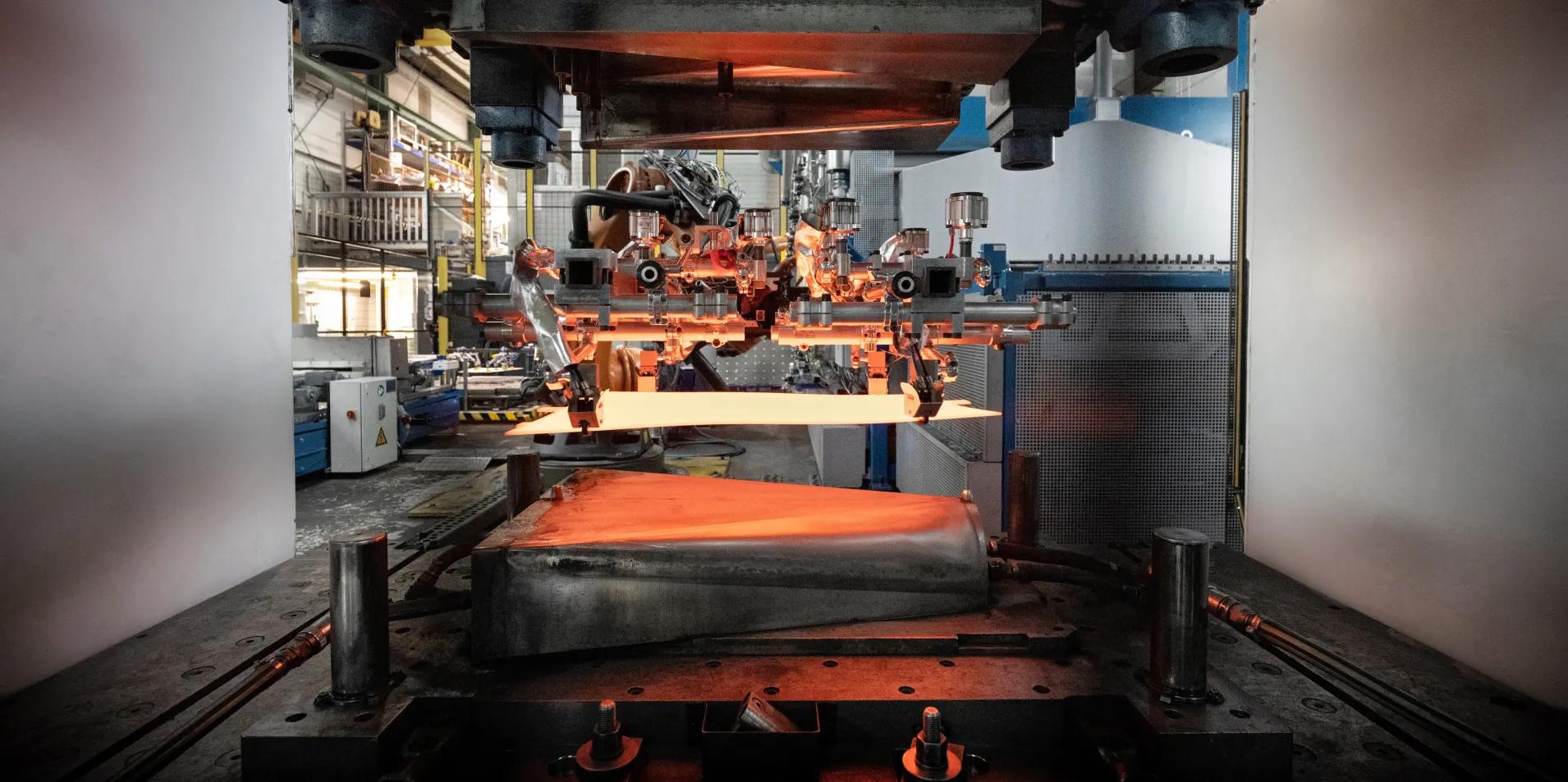

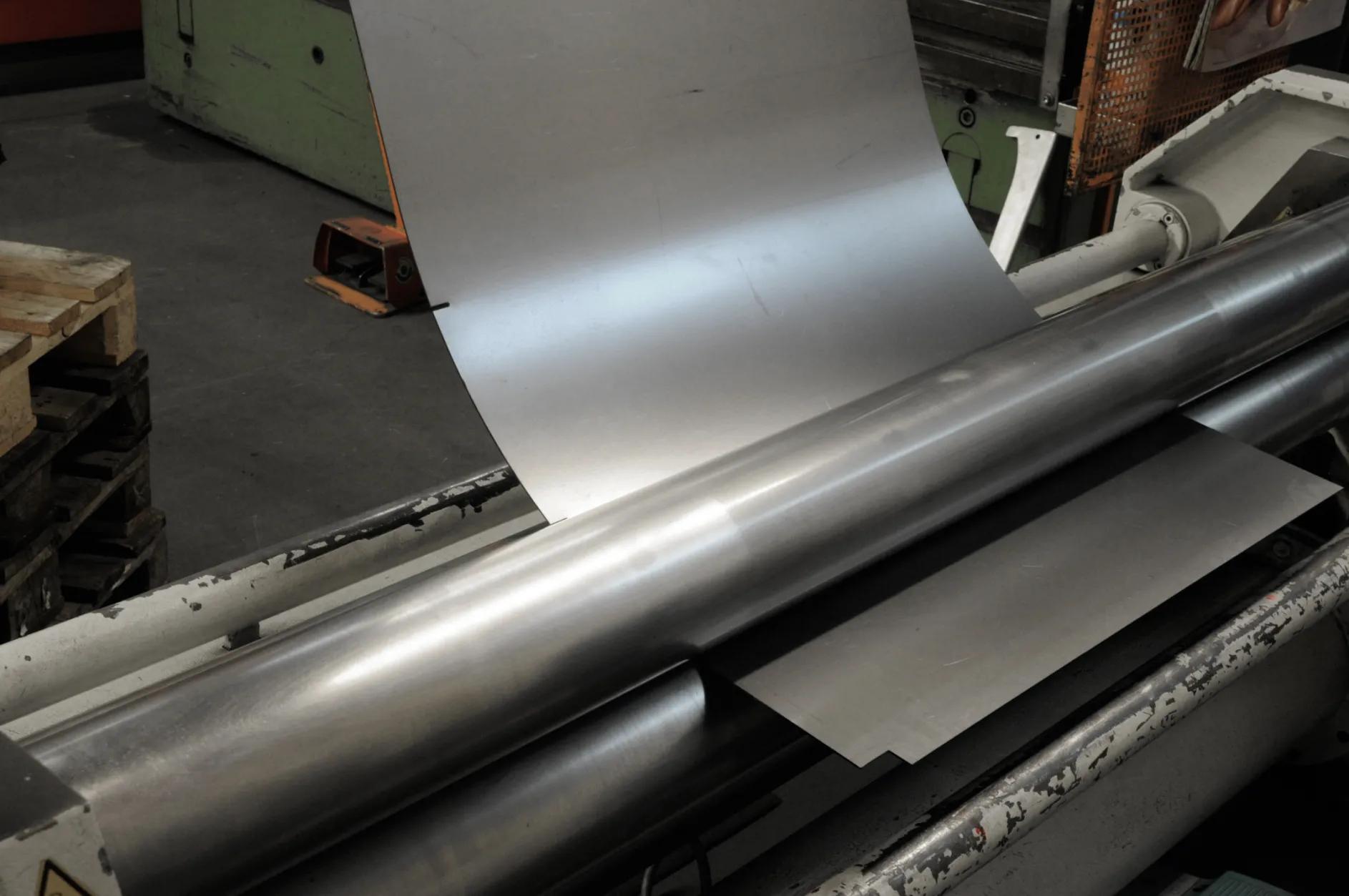

Pressing plant

Our pressing plant combines extensive experience with advanced technology to manufacture components of impressive size and complexity. With a total of 12 presses, we are optimally equipped for manual and automated production of small and medium series. These include five hydraulic presses with a capacity of up to 25,000 kN and six mechanical presses – four of which have a capacity of 12,500 kN each and two of which have a capacity of 5,000 kN each. We also have a hybrid press with a capacity of 8,000 kN, which is used for both cold and hot forming of particularly stressed components. With table surfaces ranging from 1,000x2,500mm to 5,000x3,000mm, our presses enable the efficient forming of thin and thick sheets with a thickness of 0.5 to 8 millimeters.

Laser division

In the field of laser technology, HÖRMANN Automotive Saarland GmbH relies on state-of-the-art systems for precise 2D and 3D cutting processes. The laser center comprises seven laser systems: a 3D CO2 laser with 3kW, two 3D fiber lasers with 4kW each, two 3D large-area lasers with 2.6 and 4kW, a 2D fiber laser with 3kW, and a 2D solid-state laser, TruDisk with 6kW and a table size of 2,000x4,000mm. The versatility of our laser technology enables us to process almost all material thicknesses. The 3D CO2 laser is particularly suitable for complex cutting processes, while the 3D solid-state lasers offer maximum speed and cost-effectiveness. Our large-scale CO2 system impresses with a generous working area of 4,500x2,500 mm for processing larger workpieces.

Welding

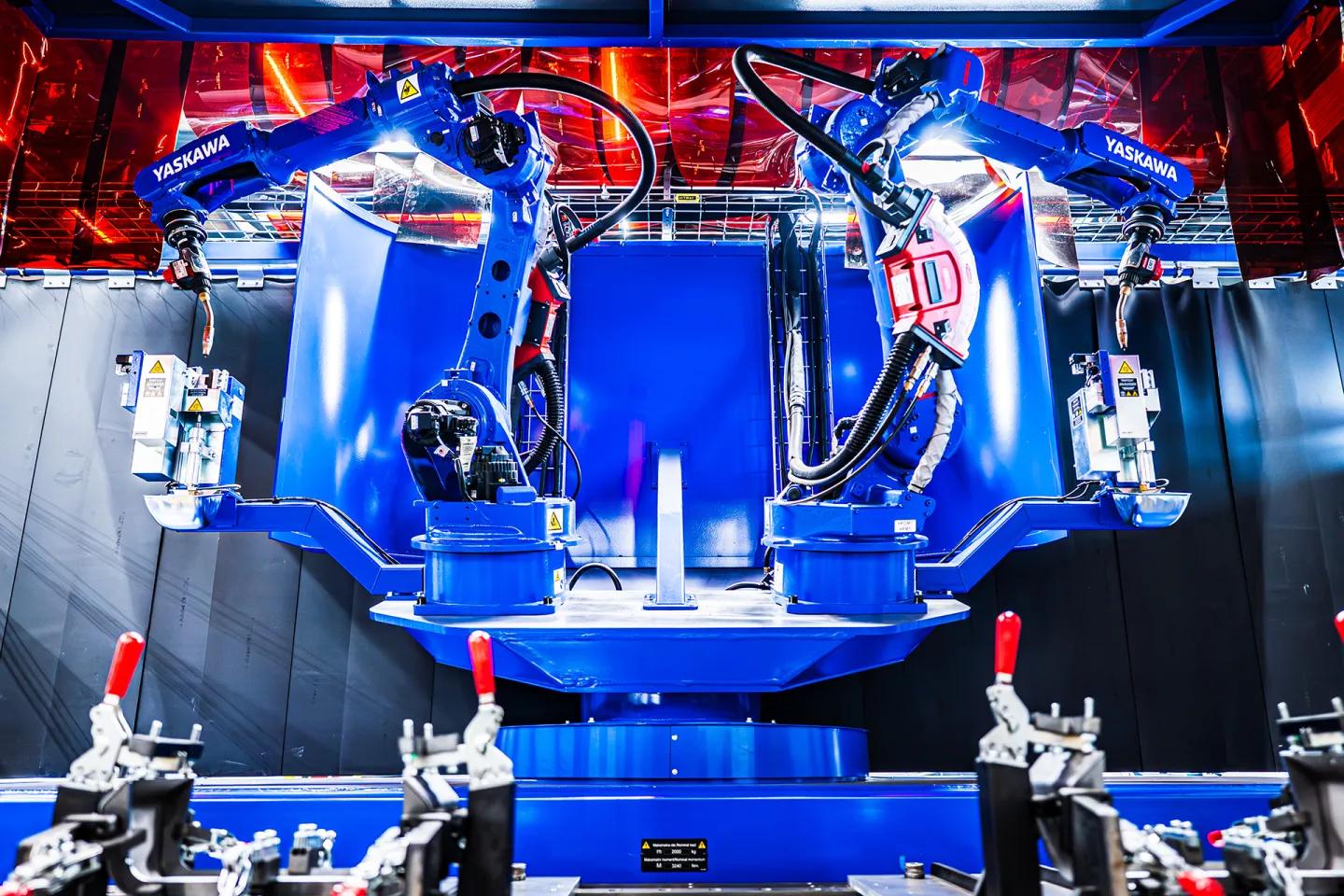

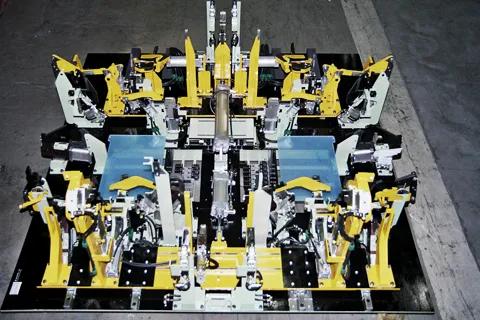

The welding department at HÖRMANN Automotive Saarland GmbH offers a wide range of welding processes that can be carried out both manually and automatically. Processes such as MIG, MAG, TIG, MIG brazing, and spot welding, together with specially manufactured welding fixtures, ensure maximum precision and quality. Our technological capabilities are expanded through the use of welding robots from CLOOS, YASKAWA, and KUKA. With our existing equipment, components up to 8.5 meters in length and weighing up to 2 tons can be manufactured automatically. Our welding processes are certified according to DIN EN ISO 3834-2.

Assembly

Our experts manufacture high-quality components according to customer requirements. Using techniques such as spot welding, riveting, clinching, screwing, gluing, and flanging, both raw and painted components are assembled with precision. The processes also include foiling and marking the components according to individual customer requirements, ensuring high quality and optimal customer satisfaction.

Efficiency in logistics, quality and digitalisation

Efficient logistics processes ensure the timely delivery of all manufactured components “just-in-time” (JIT) or “just-in-sequence” (JIS) worldwide. Our commitment to excellence in all areas—from development and production to logistics—is ensured by IATF 16949-certified processes that meet the highest standards of the automotive industry. This is supported by the use of state-of-the-art measurement technology such as coordinate measuring machines, mobile measuring arms, 3D scanners, and augmented reality software for quality assurance.

Another milestone in the digitalisation of our production is the introduction of the Hydra X Manufacturing Execution System (MES). The system is used to collect and evaluate machine and operating data (MDR/PDA). This enables us to record production figures in real time, minimise downtime and specifically improve process quality. The introduction of MES Hydra X was supported by funding from the European Union and is an important step towards digitalised, sustainable production.

With expertise, passion and state-of-the-art technology, our employees manufacture products that perfectly combine design and functionality, guarantee the best quality and offer sustainable solutions.

HÖRMANN Automotive Saarland GmbH

Essener Straße 3

D-66606 St. Wendel

T +49 6851 8005-300 • F +49 6851 8005-370

info.saarland@hoermann-automotive.com

Company headquarter:

Am Stahlhammer 65

D-66121 Saarbrücken

Your Contact

Technical Managing Director

Dipl-Ing. Martin Klein

Head of Sales Saarland

Tihomir Bijelonjic – Technischer Betriebswirt

Diversity is our strength

Careers at HÖRMANN

The HÖRMANN Group has been at the forefront of innovation for more than 60 years. HÖRMANN Automotive is part of the HÖRMANN Group.

Due to the HÖRMANN Group continuously investing in the employees’ expertise and state-of-the-art technologies, the family company has grown to include 30 affiliated companies. And this together in four successful divisions: Automotive, Engineering, Communication and Services.

HÖRMANN solutions help customers to go a step further – or make a quantum leap. Our recipe for success: the corporate culture of a family company with the freedom to develop new ideas, a strong team spirit, and employees who want to make a difference.

Why work for HÖRMANN?

Added value, not just added workload

Getting better to remain good

Sharing knowledge means multiplying knowledge

Quality comes from doing

Lateral thinkers who think ahead

We ask the right questions rather than simply giving the first available answer. We work closely with customers to understand their needs. And what will really help them. The result: solutions with a long-term impact that make our customers more competitive.

We develop continuously in discussions with colleagues, through vocational training and by embracing new professional challenges. Within the company – or the entire Group.

We live the team culture of a family company that likes to share experience and expertise. Across project teams, companies and segments. The impetus is provided by each individual. The best solutions are created together.

We are doers. What we do impresses customers. But first it has to impress us. All of our employees take quality personally, are justifiably proud of their achievements and are compensated attractively for their work.

We think broadly with a view to making things better. Four segments, 27 companies, around 3,000 employees – we have many strengths. As a family company with a long tradition, we invest sustainably. We shape change with foresight

Unsere aktuellen Stellenangebote

HÖRMANN Automotive – Part of the HÖRMANN Group

HÖRMANN Automotive GmbH consists of six high-performing companies with decades of experience in the development, production, assembly and logistics of components for the automotive industry.

Our plants are specialised in small-, medium-, and large-volume metal components as well as individual one-off products. With our core competencies, we aim to meet the daily needs of the commercial vehicle, agricultural machinery, construction, automotive and automotive supplier industries.

Strategic Business Segments

The business of HÖRMANN Automotive can be divided into three strategic business segments: Truck, Off-Road and E-Mobility.

- In the “Truck” business segment, we are specialised in the production of frame and BiW components for commercial vehicles. Particularly with regard to the commercial-vehicle frame, we cover a holistic technology portfolio with the production of longitudinal frame members, detachable frame components, welded assemblies and pipes and are available to our customers as a system partner. Due to our extensive technological expertise, we already provide our customers with valuable input and advice on cost-efficient and innovative component design at an early stage of the product creation process.

- The “Off-Road” business segment gives us wide-ranging access to customers thanks to a broad technology portfolio. We are specialised in flap systems for agricultural machinery and buses, tank systems for agricultural and construction machinery as well as complex welded assemblies for off-road requirements. Here, too, we support our customers in the area of product creation as an active development partner thanks to our extensive expertise in this technology.

- Future mobility is being influenced in a lasting manner by electrification; this will allow new solutions in many of our customer sectors. We are responding to these requirements and potential with the aspiration to actively shape future mobility, e.g. via the assembly of charging stations or components for electric vehicles. In the “E-Mobility” business segment, we thus feel obliged to develop and deliver innovative system solutions in line with demand and consistently orientate our actions – including in the “Truck” and “Off-Road” areas – to this obligation.

The successful growth course enjoyed by HÖRMANN Automotive is thanks to its committed and highly qualified employees, the unique technological position in our business segments and over 50 years of experience in the global automotive market. Every single component constructor at HÖRMANN Automotive is part of a coordinated production system – thanks to the intensive exchange of knowledge, accelerated development processes in ecosystems and digital networking in the HÖRMANN Group. Furthermore, we shape future mobility with our customers and together accompany new products every step of the way to market maturity.

HÖRMANN Automotive develops and constructs the components for a whole.

Management

Managing Director

Dr.-Ing. Michael Radke

HÖRMANN Automotive GmbH is Part of the HÖRMANN Group

HÖRMANN Automotive GmbH is part of a strong group – the HÖRMANN Group. The HÖRMANN Group has grown steadily since its formation in 1955. HÖRMANN Holding GmbH & Co. KG is the parent company of 30 subsidiaries operating in the Automotive, Communication, Engineering and Services segments with a high degree of entrepreneurial initiative and independence.

The objective of the HÖRMANN Group is to provide customers with economic, innovative and sustainable solutions and services that offer them significant advantages and clear benefits. The Group, which has approximately 3,000 highly qualified employees, uses the entire scope of its widely diversified and networked knowledge from the extremely diverse technological areas to achieve this goal.

Due to the range of diversified, highly qualified technologies and services, the Group aims to make itself independent of economic influences and to thus minimise the risk for the companies and their employees.

Thinking and acting in this way creates the space to develop perfect customer solutions using our vision, motivation and passion. A concept that is impressively confirmed by the success and continuous growth experienced by the HÖRMANN Group.

HÖRMANN Automotive is Part of a Strong Group of 27 Affiliated Companies

The companies of the HÖRMANN Group are always situated in the best possible strategical and logistical locations for our customers.

The company locations of the HÖRMANN Group in Germany are shown on the interactive map.

HÖRMANN Automotive ist Teil einer starken Gruppe mit über 30 Gesellschaften

Die Unternehmen der HÖRMANN Gruppe finden sich immer in strategisch und logistisch bester Lage für unsere Kunden.

Auf der interaktiven Karte sind die Unternehmensstandorte der HÖRMANN Gruppe in Deutschland zu sehen.

HÖRMANN Automotive Gustavsburg GmbH

HÖRMANN Automotive Gustavsburg GmbH is specialised in the production of high-quality chassis, body and add-on parts for the highly competitive commercial vehicle and automotive industries. All this is embedded in a complete process chain with a mature logistics concept – from the idea to the finished system.

Chassis, body and add-on parts for the commercial vehicle and automotive industries

Innovative technology and state-of-the-art solutions in forming, welding and automation technology as well as processes involving coil lines, press lines for up to 5,000 tonnes and laser centres for high-strength steels up to 12 millimetres make vehicles components “Made in Gustavsburg” top-quality products in their field.

Approximately 120,000 tonnes of steel are processed every year in the over 90,000 square metre production area. The range of the technologies used extends from coil cutting, forming, roll forming, laser cutting, pipe bending, welding and coating to the assembly of the finished components. Embedded in a mature logistics concept, they are made available for delivery in accordance with the JIT/JIS method.

Precision work in forming, joining technology, coating and assembly ensure the outstanding quality of all products and processes. Our in-house engineering with toolmaking guarantees prompt and excellent solutions even in the product creation process. And then there is our decades of experience in this field. HÖRMANN Automotive in Gustavsburg is thus one of the leading manufacturers of forming-related products for the commercial vehicle industry in Europe.

HÖRMANN Automotive

Gustavsburg GmbH

Ginsheimer Straße 2

D-65462 Ginsheim-Gustavsburg

T +49 6134 588-0 • F +49 6134 588-501

info.gustavsburg@hoermann-automotive.com

Your Contact

Managing Director Technology & Innovation

Dr. Wolfram Schmitt

From the idea up to series production

HÖRMANN Automotive ist in verschiedenen Branchen der Nutzfahrzeugindustrie unterwegs und verfügt über vielfältige Referenzen.

Referenzen

Rahmenlängsträger und Rahmenanbauteile für Truck

Rahmenlängsträger und Rahmenanbauteile für Truck

Hydrauliktanks für Baumaschinen

Kabinenteile für Traktoren

Medienführende Leitungen für Traktoren

Komponenten für Ladesäulen

Entwicklung, Betriebsmittelbau und Fertigung Rahmenlängsträger und Rahmenanbauteile sowie großflächige Feinblechkomponenten aus Stahl und Aluminium für MAN

Entwicklung, Betriebsmittelbau und Fertigung Rahmenlängsträger und Rahmenanbauteile sowie großflächige Feinblechkomponenten aus Stahl und Aluminium für DAF

Entwicklung, Betriebsmittelbau und Fertigung von Hydrauliktanks bis 1.600 Liter für Liebherr

Entwicklung, Betriebsmittelbau und Fertigung umgeformter, gelaserter, montierter und lackierter Klappensysteme für Claas JAGUAR

Entwicklung, Betriebsmittelbau und Fertigung umgeformter und gelaserter Serienbauteile für die 5R-Traktor-Serie von John Deere

Entwicklung und Fertigung von Komponenten für Ladesäulen von Wirelane

Produkte

Chassis

Body-in-White

Seitenverkleidungssysteme

Busdecken

Kraftstoff- und Hydraulik-Behälter

Schweißsysteme

Pressteile

Kraftstoff-und Kältemittel-Rohre

Aluverkleidungen und -klappen

Schweißkomponenten

Verpackung von Komponenten

Vorrichtungsbau

Wir bieten Fahrzeug-Chassisteile, Fahrzeug-Anbauteile, Oberflächentechnologien, produktionsspezifische Schnitt-, Biege- und Ziehwerkzeuge, Rahmen-Vormontage, Just-In-Sequence- und Modulbelieferungen.

Wir liefern alles, was die Karosserie-Außenhaut eines Automobils ausmacht.

Wir liefern lackierte und vormontierte Seitenverkleidungsteilen für Erntemaschinen, die "just-in-time" an das Hauptmontageband geliefert werden.

Produktion und einbaufertige Montage von Innenausstattungssystemen für Nutzfahrzeuge, insbesondere von Deckensystemen

Wir besitzen jahrzehntelange Erfahrung in der Herstellung von Kraftstoff- und Hydrauliktanks.

Wir fertigen komplette Fahrgestelle für Düngemittelfahrzeuge und neuerdings auch für einen Feldhäcksler.

Nach dem Bedarf unserer Kunden, die vorwiegend aus der Land- und Baumaschinentechnik kommen, konzipieren wir Produkte für ganz spezielle Anforderungen.

In der Fertigung von einbaufertigen Rohrsystemen für den Transport von Kraftstoffen und Kältemitteln in Bussen und PKW besitzen wir ein in jahrzehntelanger Tätigkeit erworbenes Fertigungswissen.

Die Fertigung von Kofferraum- und Tankklappen sowie Verkleidungen aus Aluminium für Busse und Nutzfahrzeuge gehört neben den Tanks zu unseren Kernkompetenzen.

Wir fertigen vorwiegend achstragende Fahrwerkteile verschiedener Komplexitätsgrade, die wir – zu Schweißbaugruppen und -komponenten montiert – direkt ans Band liefern.

Wir übernehmen die Gesamtverantwortung für die Verpackung und Lieferung von Ersatzteilen, CKD-Komponenten und Kit-Lösungen.

Wir planen und fertigen innovative Vorrichtungen, mit deren Hilfe die verschiedenen Einzelteile eines Endproduktes oder komplexerer Komponenten maßhaltig miteinander verschweißt werden können.

Arbeiten bei einer dynamischen Unternehmensgruppe

Wir sind ein attraktiver Arbeitgeber für engagierte und leistungsorientierte Mitarbeiter.