Packaging of Components for the Replacement Part and CKD Markets

We assume overall responsibility for the packaging and delivery of replacement parts, CKD components and kit solutions. This includes the packaging planning, coordination of the supply chain and on-time delivery. Thanks to intelligent packaging design, we create ideal cardboard boxes and containers to guarantee cycle times that are as fast as possible and high transport protection. The packaging of parts takes place in an order-related manner and in accordance with the highest quality standards. If desired, the replacement parts are provided together with operating instructions, add-on parts and small parts for installation at the dealer and delivered as a kit. The CKD parts and pre-assembled units for the foreign markets are packaged in special overseas containers and loaded in containers.

We deliver as per your desired delivery instructions via truck, railway train, maritime freight, air freight or, if desired, also directly to the dealers. We also complete the customs clearing of the goods for you for foreign shipments. Our partners for the local added value abroad are located in the USA, China, South Africa and Egypt.

Thanks to our in-house software, which calculates the optimal container utilisation for each delivery, and our many years of cooperation with our global network of innovative logistics partners, we can offer you this comprehensive complete package at favourable conditions.

Our range of services covers the following:

- Process planning

- Investment for the required systems and tools

- Packaging planning and development

- Procurement of components (alternatively provided by the customer) and packaging materials

- MRP of components and packaging materials

- Transport coordination for all incoming goods

- Calculation of optimal container utilisation

- Packaging of the offer scope in replacement part or CKD packaging

- Monitoring of supply chain, supplier management, supplier development

- Change management for components

- Customs declaration and clearing

- Delivery of goods to suit customer requests, if necessary via partners to increase the local content level

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Wackersdorf here.

Ready-To-Install Modules

Already today, we supply one of our customers with painted and pre-assembled side trim parts for harvesting machines that are delivered just-in-time to the main assembly line. In the future, this service is to be intensified and optimised. The most important success factors for this are customer proximity, communication and high logistical competence. We have made these characteristics our principles, and our employees stand for professional cooperation with our customers on a partnership basis.

Our range of services covers the following:

- Development and planning

- Prototyping

- Welding, riveting, adhesive bonding, edging, screwdriving

- Coating

- Final assembly

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in St. Wendel here.

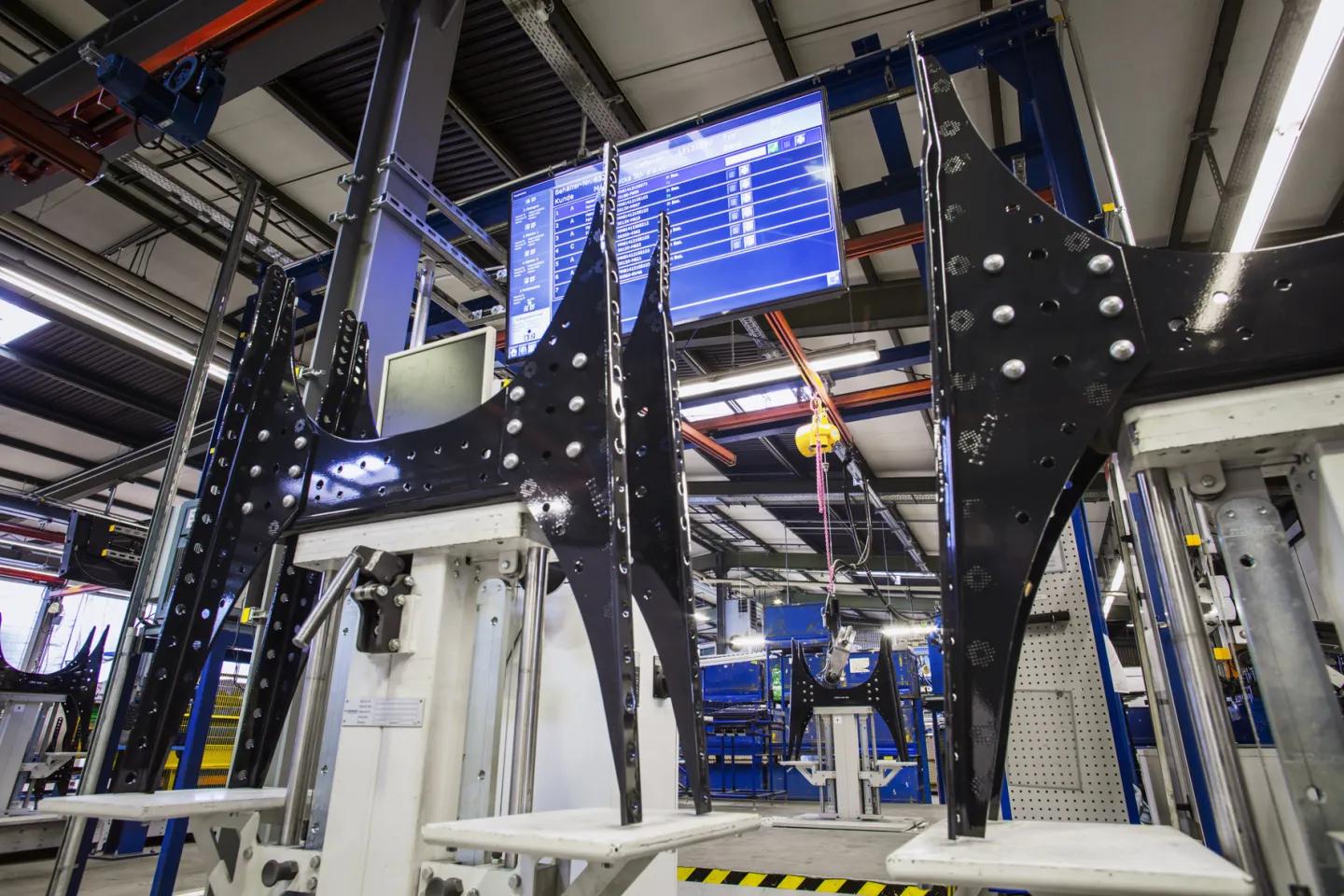

Manufacturing of Jigs and Fixtures

Over the many years of cooperation, our customers have built up confidence in our expertise to the extent that they also hand over tasks to us that expand our range of services. The Manufacturing of Jigs & Fixtures area at Hörmann Automotive is an example of such cooperation. We plan and produce innovative jigs and fixtures by means of which the various different single parts of an end product or more complex components can be welded together in a dimensionally stable manner. We supply companies from various different sectors, including Mercedes-Benz, with customised overall solutions from the idea to acceptance by the customer and also produce the jigs and fixtures for our own requirements.

Our range of services covers the following:

- Consultation

- Planning/engineering

- Machining

- Assembly

- Quality assurance, i.e. function check and final inspection

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Saarbrücken here.

Welded Systems

Our latest product range involves the production of welded systems for agricultural machinery. For approximately four years now, we have been producing complete chassis for fertiliser spreaders/manure tanks and recently also for a forage harvester. In this connection, our range of services is rounded off by the production of the associated add-on systems – such as the supporting frame for the tank or the mount for the cab. The production of such complex systems necessitates close cooperation with our customers, who we support in the long term as part of quality improvements – as well as with regard to technical simplification.

Our range of services covers the following:

- Production of complete chassis

- Lasering, edging, welding and machining

- Painting

- Quality control

- Just-in-time delivery

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Saarbrücken here.

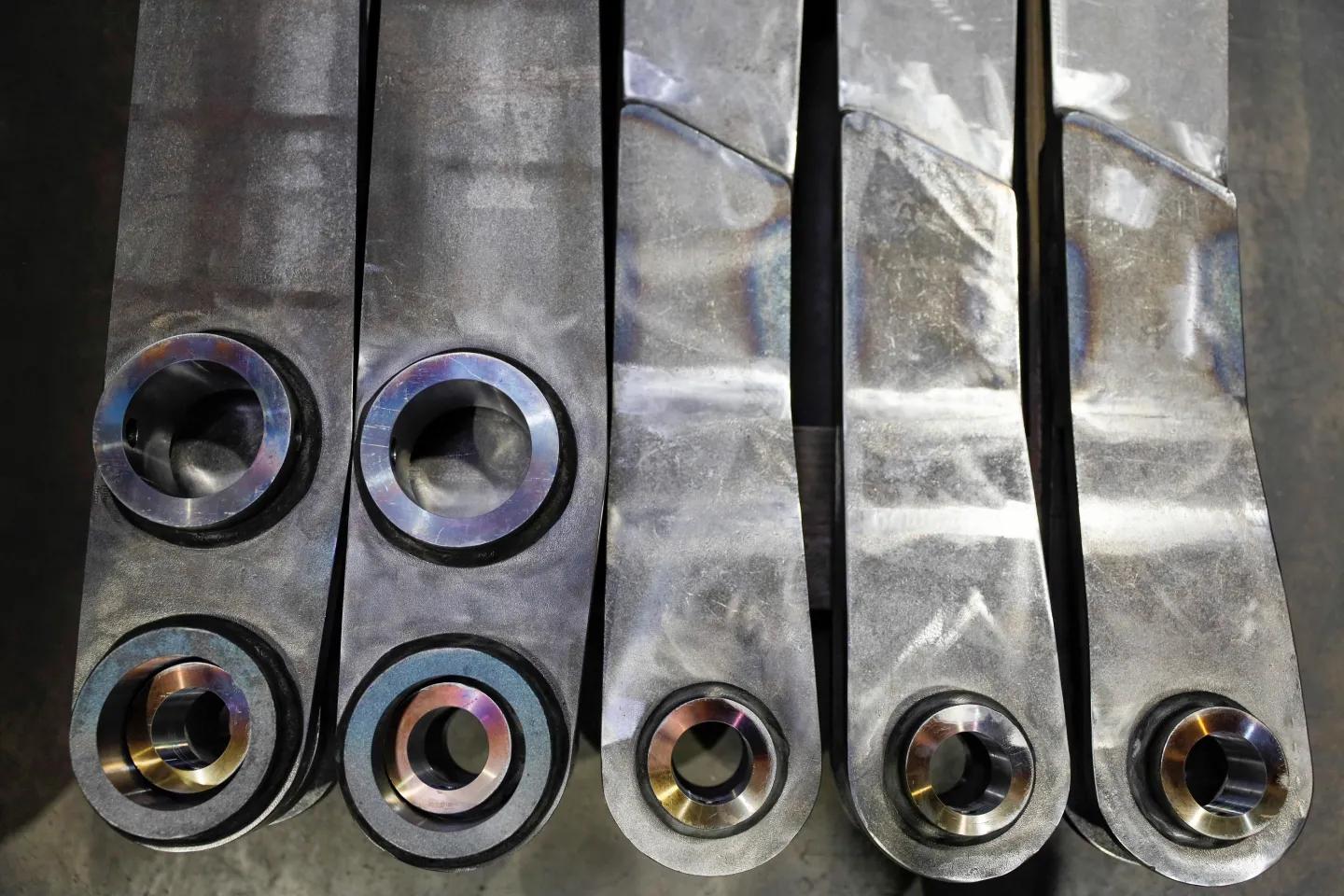

Welded Components

We mainly produce axle-supporting chassis parts with differing degrees of complexity that we deliver directly – in welded assembly and welded component form – to the assembly line. All established robot and manual welding methods (MIG, MAG, TIG) are used and adapted to the material to be welded and customer requirements. Our state-of-the-art facilities guarantee that the customer is provided in each case with the optimal method for a high throughput rate with maximum quality and the lowest possible production costs.

Our range of services covers the following:

- Production of components and replacement parts in low-volume production

- Use of all established robot and manual welding methods (MIG, MAG or TIG)

- Assembly

- Machining

- Just-in-time or just-in-sequence delivery

- Weld-seam test

- Traceability

- Anti-corrosion coating in accordance with customer specification (e.g. cathodic dip painting)

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Saarbrücken here.

Pressed Parts

We design products for very special requirements to suit the needs of our customers, who primarily come from agricultural and construction machinery technology. In the case of low to average unit figures, low tooling and process costs play an important role: Our employees have the required expertise to solve the conflict between tool and part prices so that the best possible result is achieved for our customers. Besides the usual bare or galvanised deep drawing steels, we are also experts when it comes to stainless steels, copper and aluminium. Sheet thicknesses of between 0.5 mm and 3 mm are formed as what are known as fine sheets. The wings for tractors and side trim parts for harvesting machines and tractors are given here as examples. However, we can also form thick plates of up to max. 8 mm, such as pedal levers, feed hoppers for harvesting machines and shields for exhaust systems. Presses with a pressing force of up to 16,000 kN are available for these tasks.

Our range of services covers the following:

- Development and planning

- Prototyping

- Pressing and forming of deep drawing steel, stainless steel, copper and aluminium

- Fine sheet: Sheet thicknesses of 0.5-3 mm

- Thick plate: Sheet thicknesses of max. 8 mm

- Pressing with a pressing force of up to 16,000 kN

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in St. Wendel here.

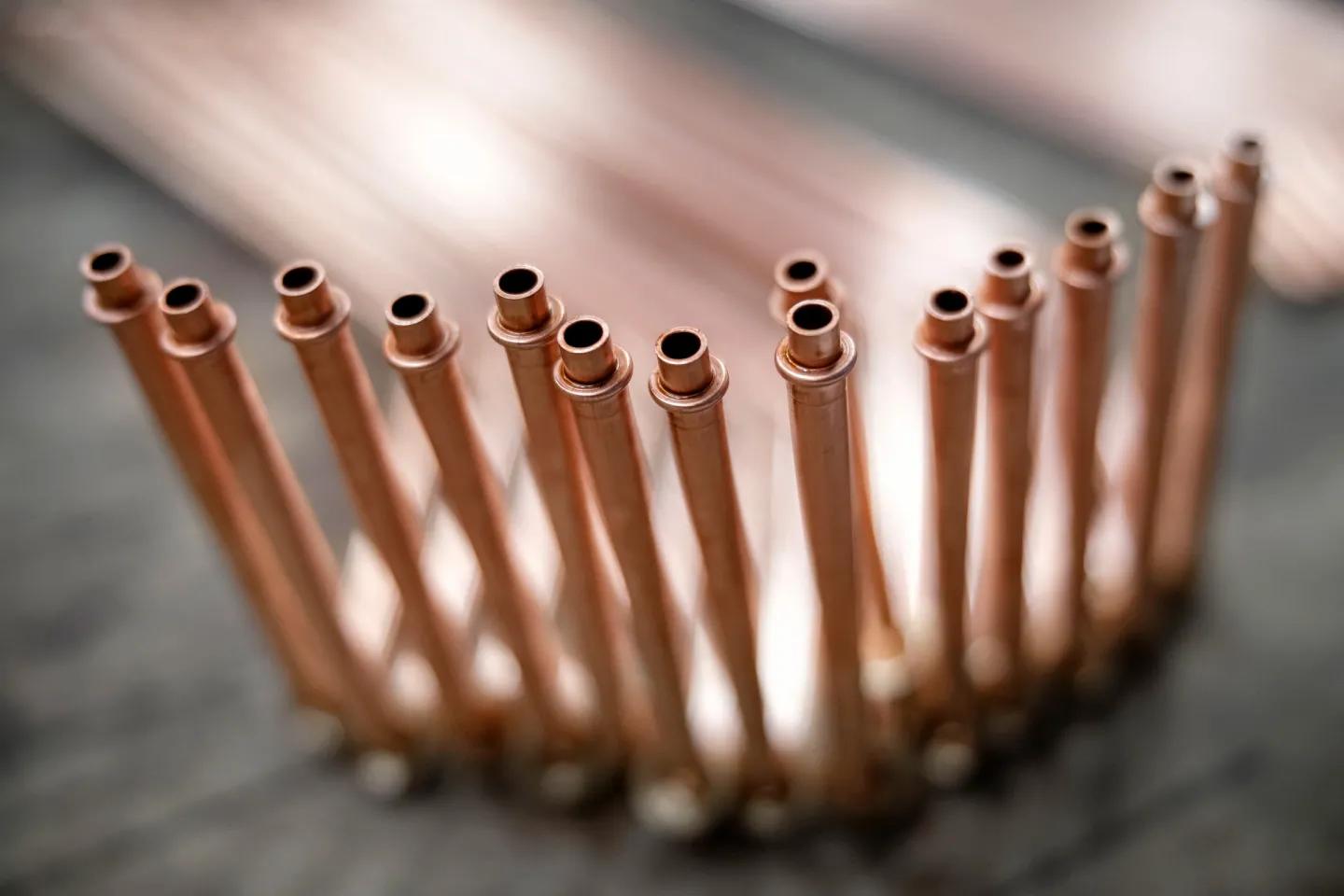

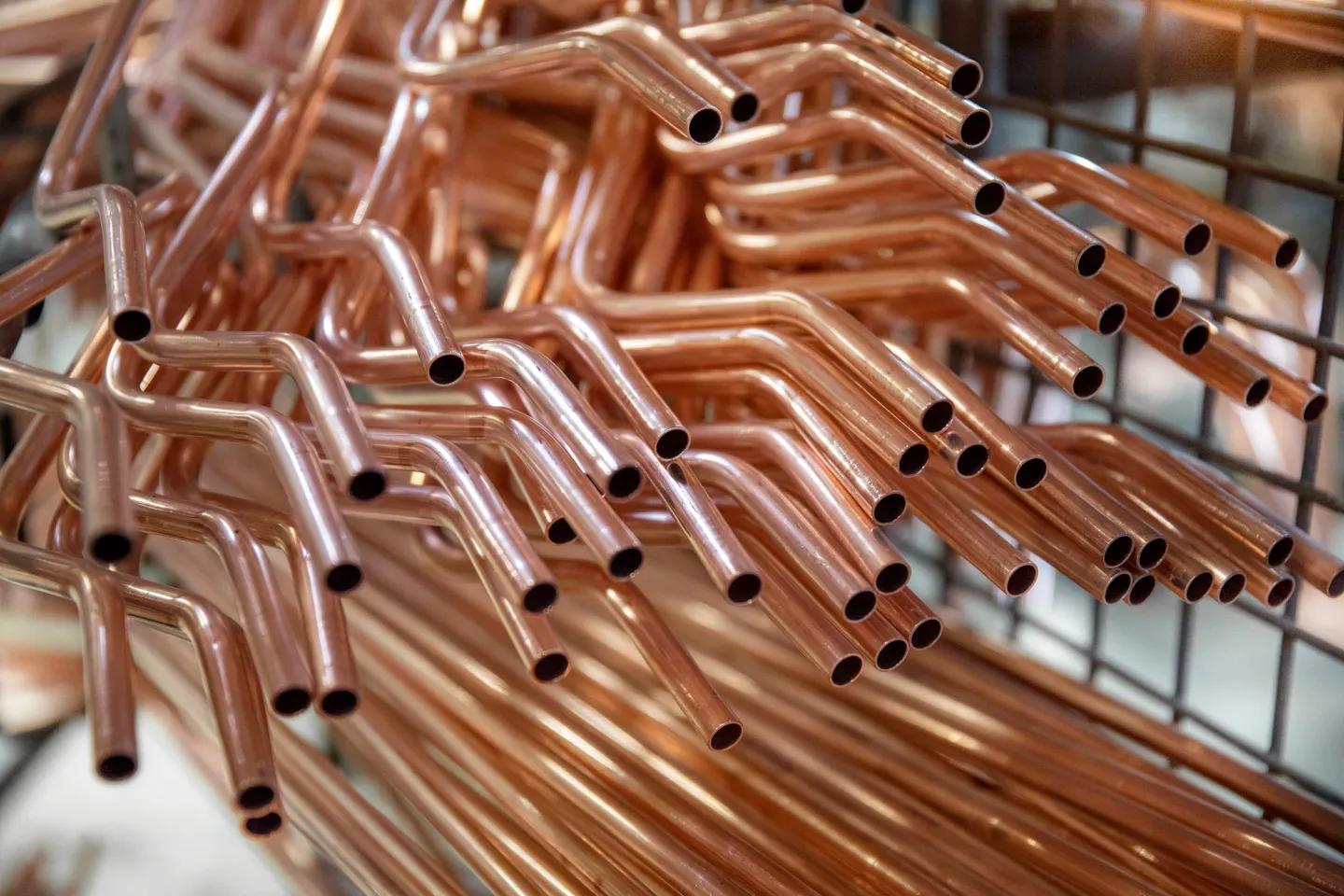

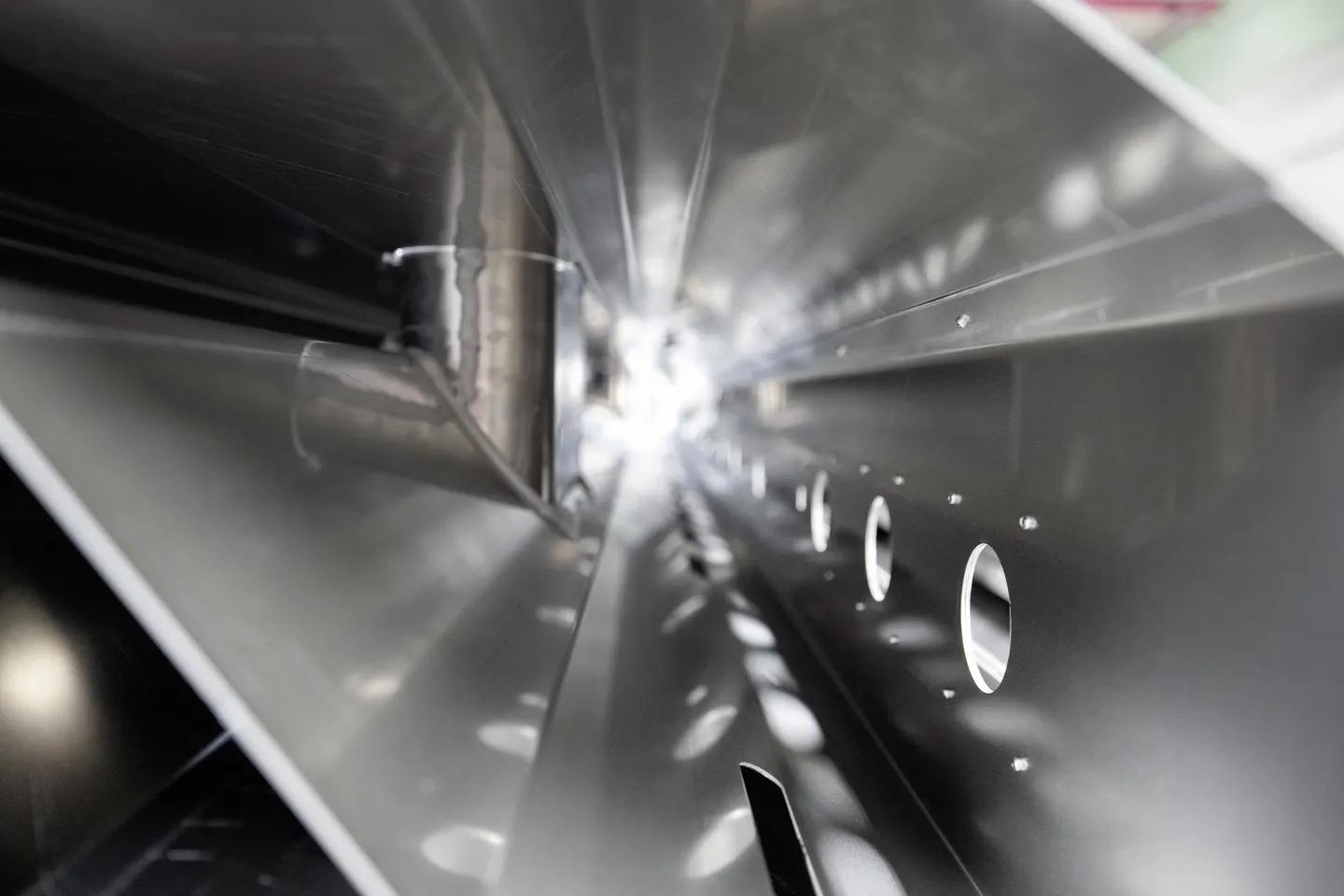

Fuel and Refrigerant Pipes

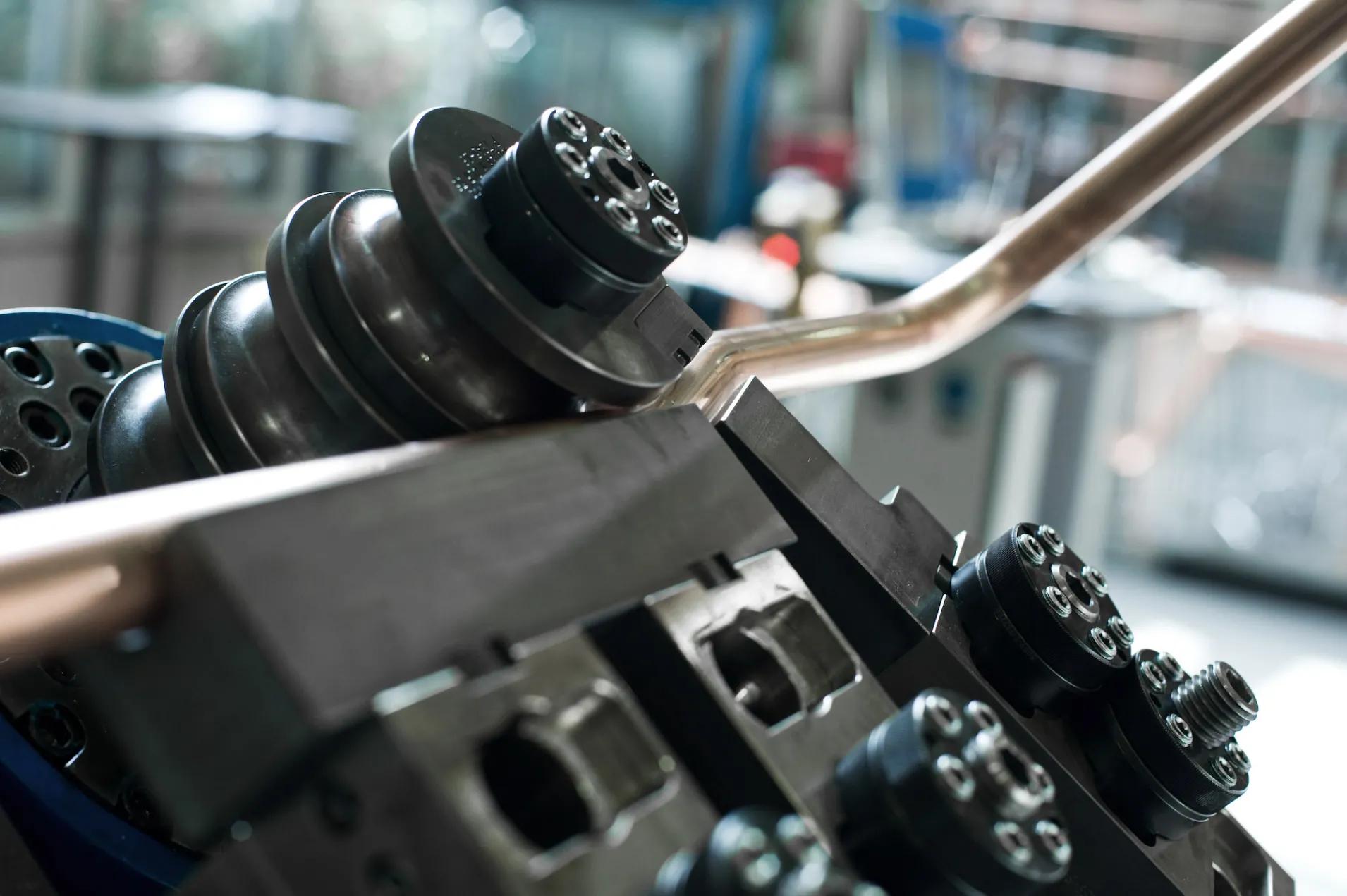

We have decades of production expertise in the manufacturing of ready-to-install pipe systems for the transport of fuels and refrigerants in buses and passenger cars. In the meantime, we have delivered tens of thousands of complete pipe systems to OEMs. Depending on customer requirements, we form pipes made from steel, stainless steel, copper, brass or aluminium on state-of-the-art CNC bending machines and provide the pipe ends with suitable and stable connections. Besides refrigerant and fuel lines, we can in this way also produce various other line types – for example, hydraulic lines, oil lines or coolant lines. With individually agreed logistics concepts, we contribute to a smooth production process at the customer.

Our range of services covers the following:

- Pipe bending with diameters of between 2 mm and 70 mm to suit the specified bending radius

- Bending of steel, stainless steel, copper, brass and aluminium pipes

- Attachment of connections by means of induction soldering and brazing

- Pipe end processing in accordance with the customer drawing

- Initial sampling of new lines

- Vehicle-related delivery (one-set flow), just-in-time or just-in-sequence

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Saarbrücken here.

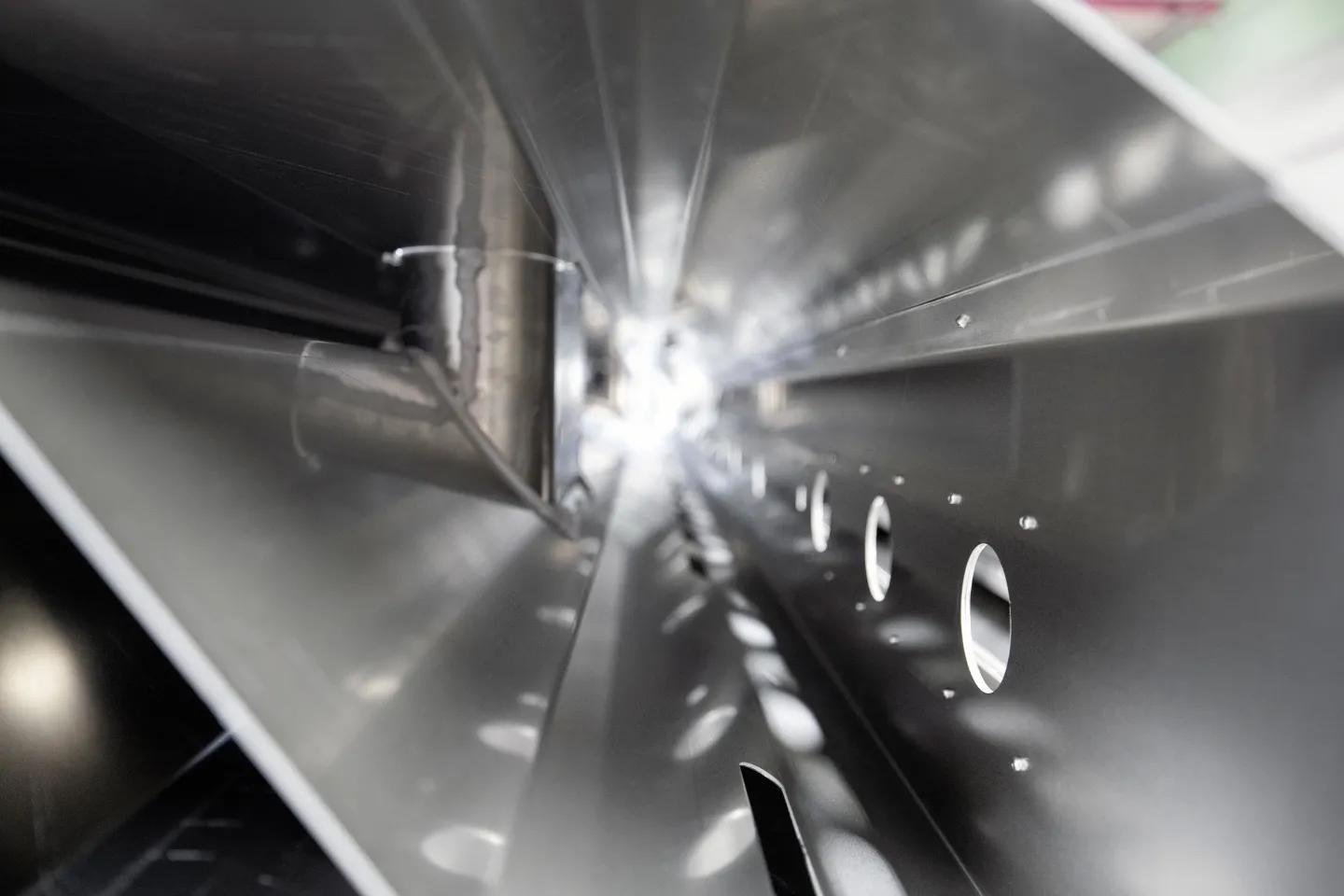

Bus Ceiling Systems

We are specialised in the production and ready-to-install assembly of interior equipment systems for commercial vehicles, in particular of ceiling systems. The ceiling systems in city buses and coaches are nowadays much more than decorative panels. These now conceal a complex structure of subsystems in a confined installation space that ensure greater safety and comfort for passengers: Functions such as cooling/air conditioning, audio and lighting must be optimally integrated in the confined installation space available. The objective here is functional reliability as well as weight reduction and ease of maintenance. We offer a comprehensive range of services for roof internal systems to suit customer requests. From the design to the development of prototypes to engineering, series production and delivery.

Our range of services covers the following:

- Engineering and series production from a single source

- Just-in-sequence delivery

- Supplier selection with regard to expertise, delivery reliability and quality

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Saarbrücken here.

Chassis

We offer our customers the following for the “chassis” area:

- Vehicle chassis parts (e.g. longitudinal frame members), also as complete, ready-to-install units with a sheet thickness of up to 12 mm

- Detachable body components and chassis parts such as crossmembers, gusset plates, reinforcements with a sheet thickness of up to 12 mm

- Surface technologies such as zinc-phosphate coating, cathodic dip painting (CDP) and topcoat systems

- Planning, design and manufacturing of production-specific cutting, bending and drawing tools

- Frame pre-assembly, just-in-sequence and module deliveries

Into quality in a big way

We produce all kinds of detachable body components and chassis parts made from sheets up to 12 mm thick and in material grades up to QStE 700 TM. The range of parts encompasses crossmembers, detachable parts, gusset plates, reinforcements and welded body components for truck frames. We have particular expertise in the joining of pressed parts to form components. In addition to CDP priming, the option exists to use an additional topcoat.

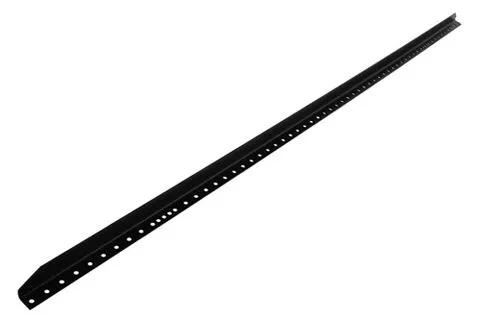

Product group: Longitudinal frame members

For light-, medium- and heavy-duty truck model series, we produce longitudinal frame members made from high-strength materials up to QStE 500 TM and in material thicknesses of up to 10 mm. Longitudinal frame members are available in straight and bent designs and with individual hole patterns. Two large presses with a pressing force of up to 50,000 kN as well as a roll-forming system for rolling the longitudinal members are available for production. The state-of the-art cathodic dip painting system is designed for maximum corrosion protection with zinc-phosphate coating via spraying and cathodic dip painting.

Product group: Detachable frame components

For light-, medium- and heavy-duty truck model series, we produce detachable frame components made from high-strength materials up to QStE 700 TM and in material thicknesses of up to 12 mm. Four press lines, production cells for assemblies and a cathodic dip painting system with pretreatment and cataphoretic immersion priming are available at two locations for production.

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Gustavsburg here.

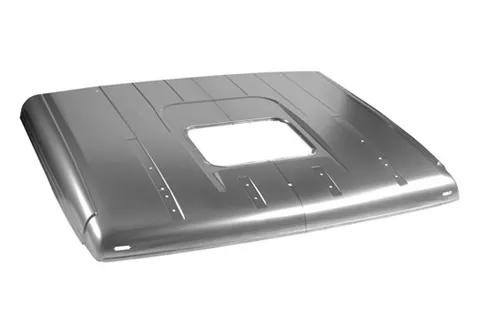

Body-In-White

Product group: Outer skin Product group: Structural parts Product group: Assemblies

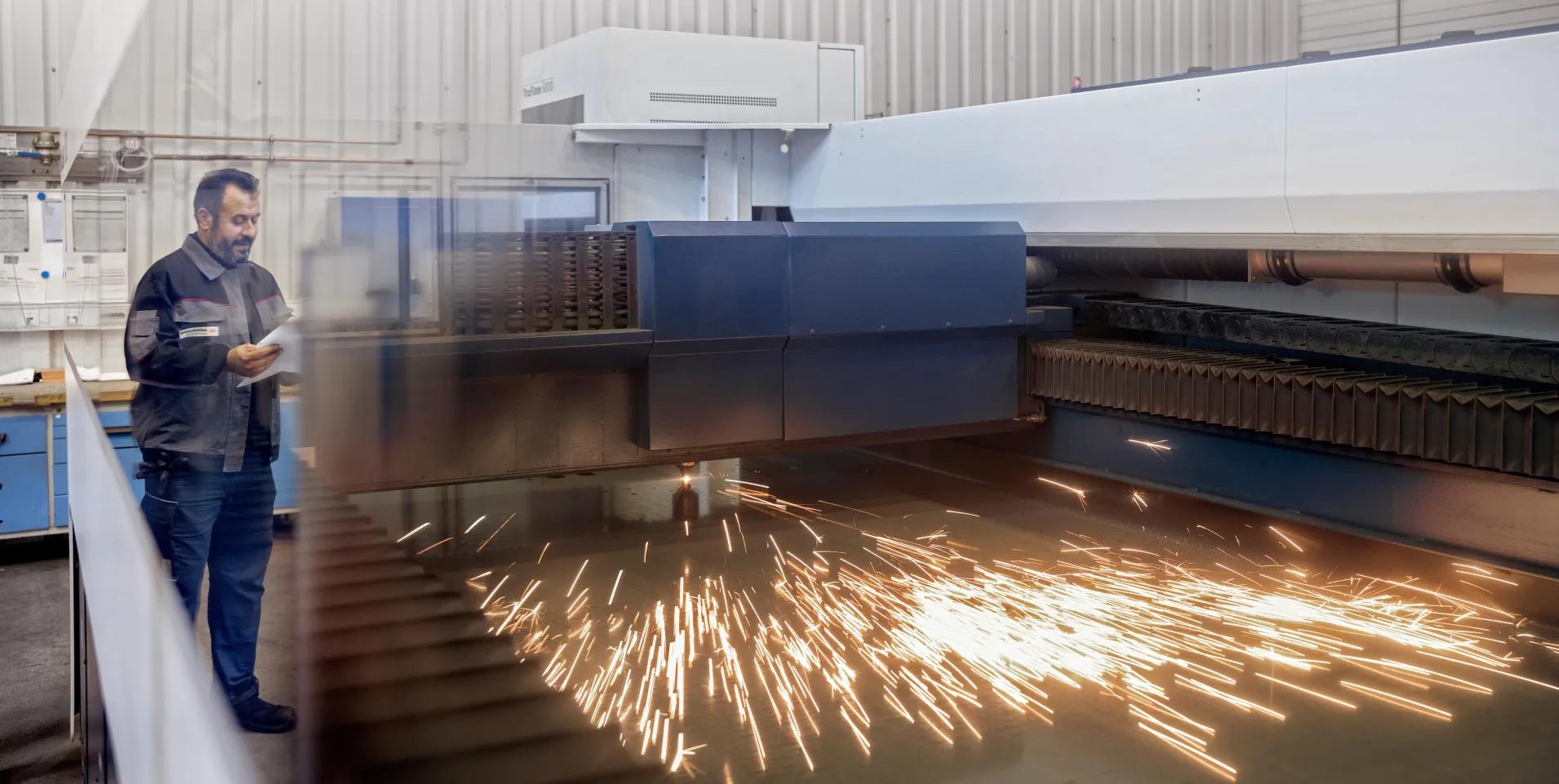

We deliver everything required to form the outer body skin of a vehicle. Our production portfolio includes body parts for passenger cars as well as cab and trim parts for trucks. We are a competent partner not just as a part producer, but also as a supplier of modules, assemblies and ready-to-install system components. Fine sheets up to 3 mm thick are processed in accordance with EN 10143 and EN 10131. Production takes place on fully automated press lines and in flexible production cells with state-of-the-art laser systems and welding and bonding robots. Our aspiration: Top quality. For example, as a supplier for outer skin parts we fulfil the exacting demands of European passenger car manufacturers.

Our range of services covers the following:

- Outer skin and structural parts up to 3.0 mm thick

- Bonding and welding technology

- Surface technologies such as zinc-phosphate coating, cathodic dip painting (CDP) and topcoat systems

- Planning, design and manufacturing of production-specific cutting, bending and drawing tools

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Gustavsburg here