HÖRMANN Automotive Saarland GmbH

Specializing in cold and hot forming, welded assemblies, piping, and interior systems

HÖRMANN Automotive Saarland GmbH specializes in the development and manufacture of high-quality cold and hot forming components, welded assemblies, piping, and ready-to-install interior systems. With over 35,000 square meters of production space and around 350 skilled employees, we serve customers in the agricultural and construction machinery industry as well as the industrial truck, commercial vehicle, and bus sectors.

Our portfolio is divided into the following three areas:

- Bodywork

The bodywork division covers structural and outer skin parts, such as side and tail doors for combine harvesters, body parts for tractors, industrial trucks, and commercial vehicles, as well as outer skin parts for camper vans and trucks. - Chassis & components

In the chassis and components sector, the company produces complex welded assemblies such as discharge manifolds for harvesters, bumpers for trucks, and large main frames up to 6.5 meters in length for forage harvesters and sprayers. It also manufactures heavy-duty components for agricultural machinery, which are particularly resistant thanks to the press hardening process. - Interior systems

The interior division specializes in the production of ready-to-install ceiling systems, air conditioning ducts, and aluminum profiles for city buses and coaches. This division also manufactures pipes for operating fluids such as refrigerants, hydraulic fluids, and fuels.

Our core competencies at a glance

Development, mechanics, and toolmaking

Our experts in design and component development have extensive experience in sheet metal forming, welding technology, and fixture construction. Using state-of-the-art CAD software such as CATIA and PAM-STAMP, we create innovative designs and carry out comprehensive feasibility studies and dynamic stress analyses. Close cooperation between our specialist mechanics and toolmakers enables the precise manufacture of complex forming tools, welding and assembly fixtures, and the development of prototype tools using sophisticated CNC machining techniques.

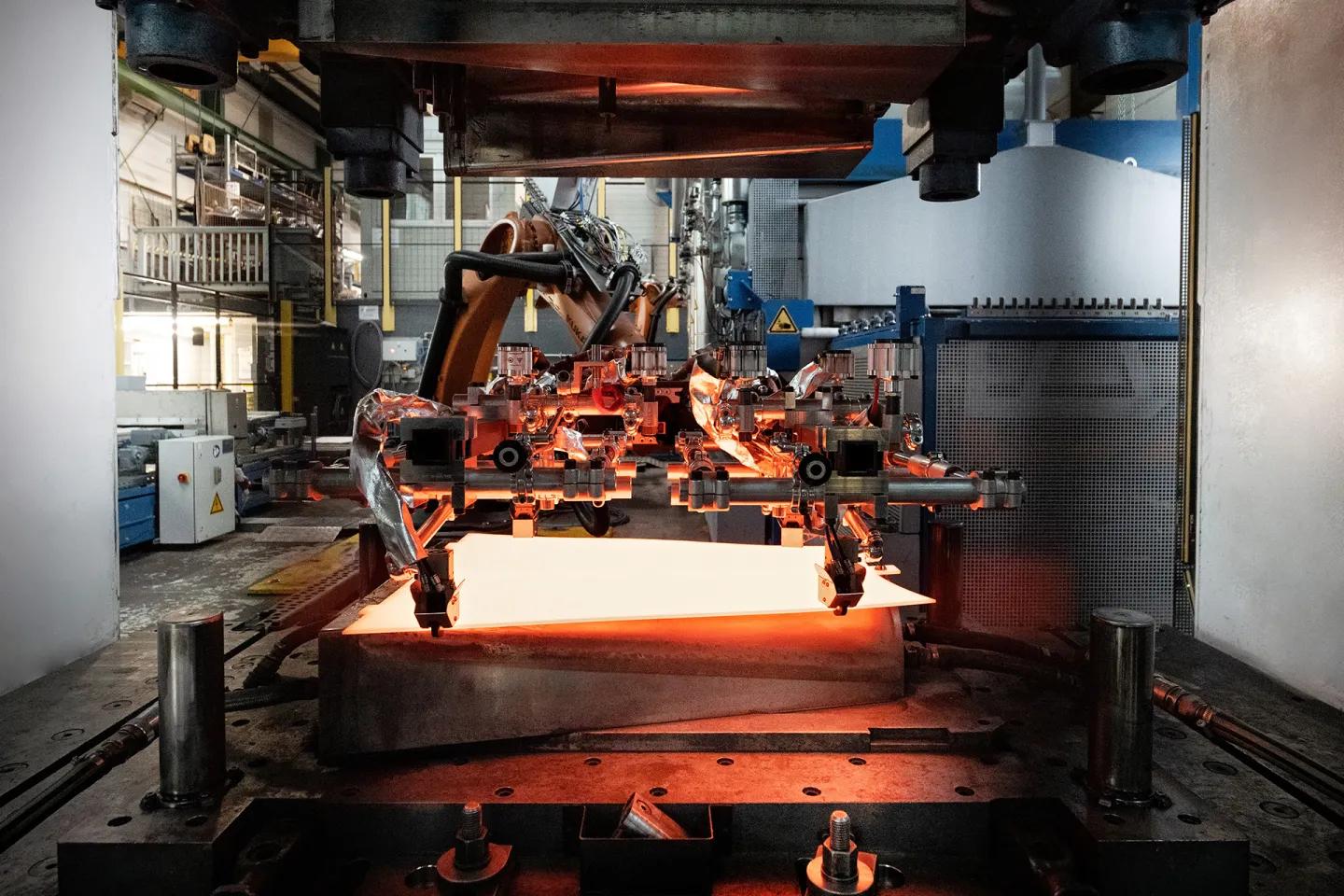

Pressing plant

Our pressing plant combines extensive experience with advanced technology to manufacture components of impressive size and complexity. With a total of 12 presses, we are optimally equipped for manual and automated production of small and medium series. These include five hydraulic presses with a capacity of up to 25,000 kN and six mechanical presses – four of which have a capacity of 12,500 kN each and two of which have a capacity of 5,000 kN each. We also have a hybrid press with a capacity of 8,000 kN, which is used for both cold and hot forming of particularly stressed components. With table surfaces ranging from 1,000x2,500mm to 5,000x3,000mm, our presses enable the efficient forming of thin and thick sheets with a thickness of 0.5 to 8 millimeters.

Laser division

In the field of laser technology, HÖRMANN Automotive Saarland GmbH relies on state-of-the-art systems for precise 2D and 3D cutting processes. The laser center comprises seven laser systems: a 3D CO2 laser with 3kW, two 3D fiber lasers with 4kW each, two 3D large-area lasers with 2.6 and 4kW, a 2D fiber laser with 3kW, and a 2D solid-state laser, TruDisk with 6kW and a table size of 2,000x4,000mm. The versatility of our laser technology enables us to process almost all material thicknesses. The 3D CO2 laser is particularly suitable for complex cutting processes, while the 3D solid-state lasers offer maximum speed and cost-effectiveness. Our large-scale CO2 system impresses with a generous working area of 4,500x2,500 mm for processing larger workpieces.

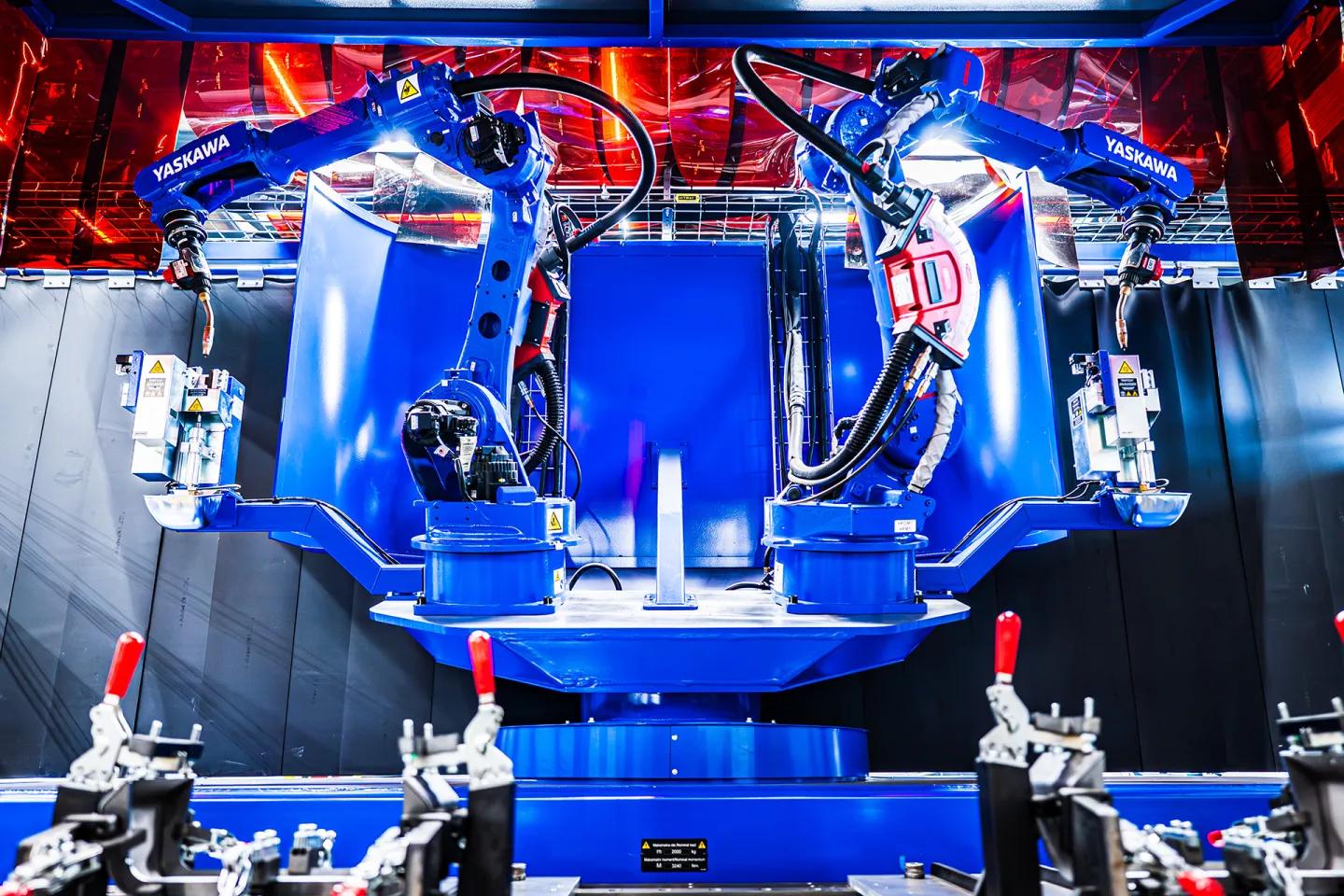

Welding

The welding department at HÖRMANN Automotive Saarland GmbH offers a wide range of welding processes that can be carried out both manually and automatically. Processes such as MIG, MAG, TIG, MIG brazing, and spot welding, together with specially manufactured welding fixtures, ensure maximum precision and quality. Our technological capabilities are expanded through the use of welding robots from CLOOS, YASKAWA, and KUKA. With our existing equipment, components up to 8.5 meters in length and weighing up to 2 tons can be manufactured automatically. Our welding processes are certified according to DIN EN ISO 3834-2.

Assembly

Our experts manufacture high-quality components according to customer requirements. Using techniques such as spot welding, riveting, clinching, screwing, gluing, and flanging, both raw and painted components are assembled with precision. The processes also include foiling and marking the components according to individual customer requirements, ensuring high quality and optimal customer satisfaction.

Efficiency in logistics, quality and digitalisation

Efficient logistics processes ensure the timely delivery of all manufactured components “just-in-time” (JIT) or “just-in-sequence” (JIS) worldwide. Our commitment to excellence in all areas—from development and production to logistics—is ensured by IATF 16949-certified processes that meet the highest standards of the automotive industry. This is supported by the use of state-of-the-art measurement technology such as coordinate measuring machines, mobile measuring arms, 3D scanners, and augmented reality software for quality assurance.

Another milestone in the digitalisation of our production is the introduction of the Hydra X Manufacturing Execution System (MES). The system is used to collect and evaluate machine and operating data (MDR/PDA). This enables us to record production figures in real time, minimise downtime and specifically improve process quality. The introduction of MES Hydra X was supported by funding from the European Union and is an important step towards digitalised, sustainable production.

With expertise, passion and state-of-the-art technology, our employees manufacture products that perfectly combine design and functionality, guarantee the best quality and offer sustainable solutions.

HÖRMANN Automotive Saarland GmbH

Essener Straße 3

D-66606 St. Wendel

T +49 6851 8005-300 • F +49 6851 8005-370

info.saarland@hoermann-automotive.com

Company headquarter:

Am Stahlhammer 65

D-66121 Saarbrücken

Your Contact

Technical Managing Director

Dipl-Ing. Martin Klein