Fuel and Refrigerant Pipes

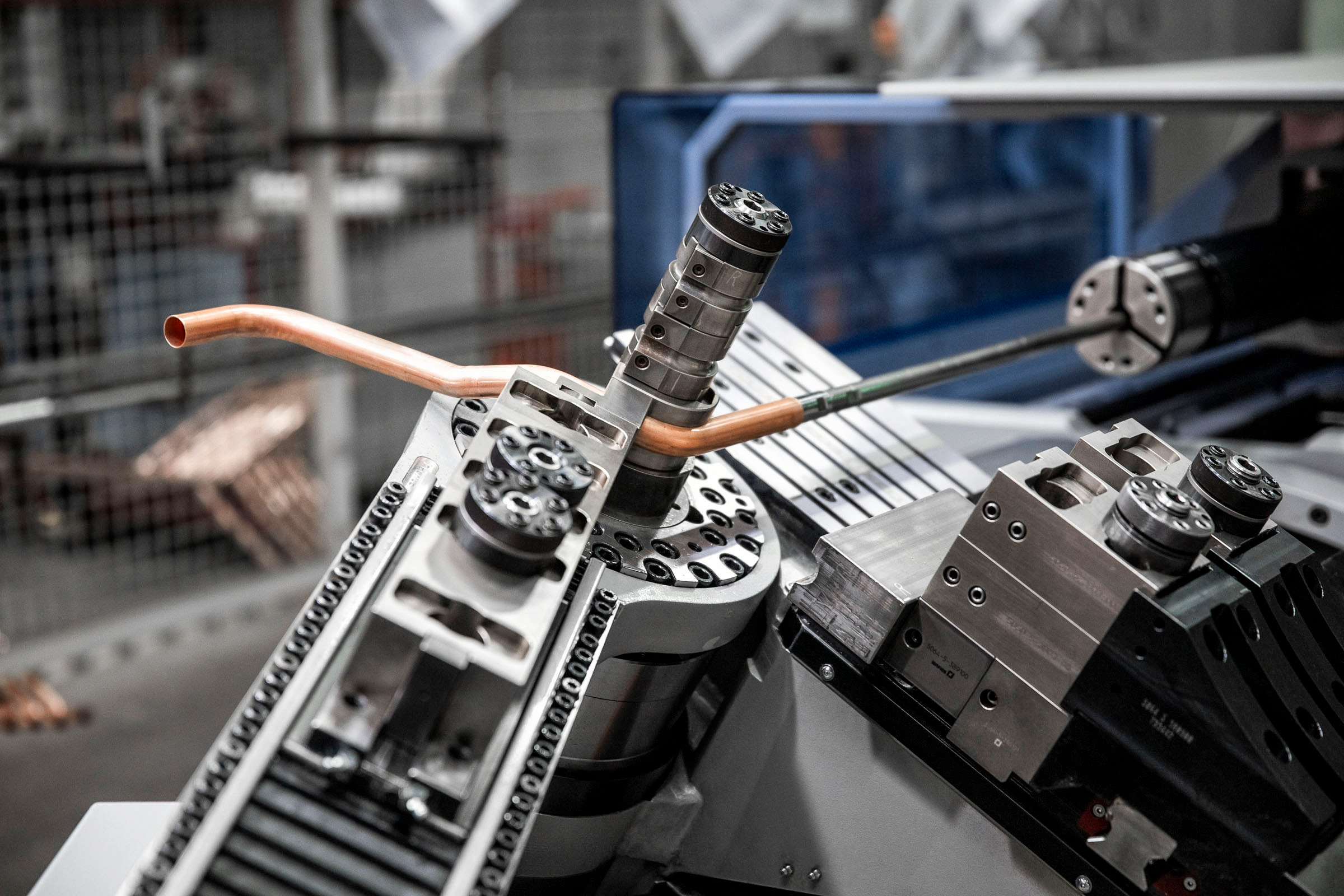

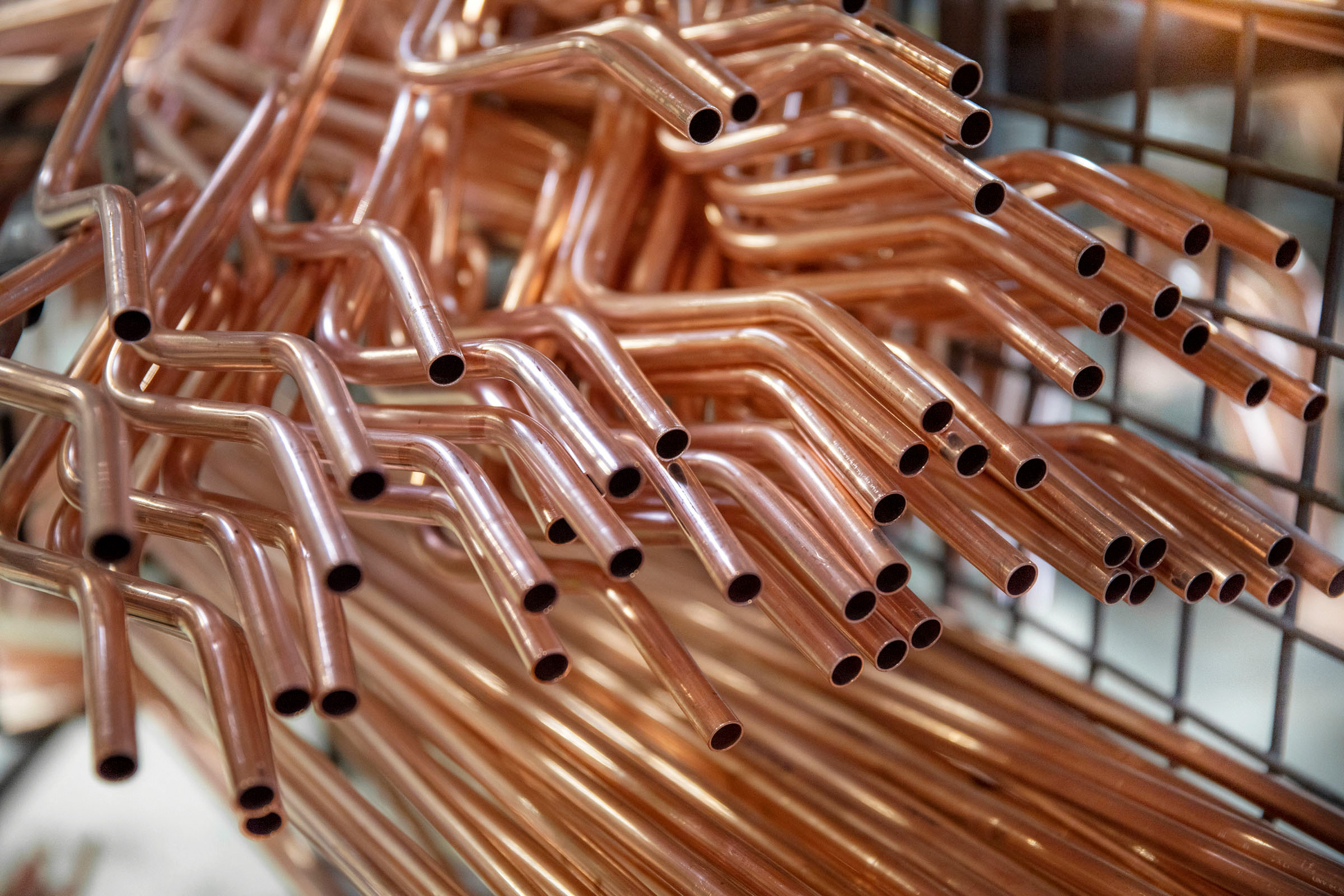

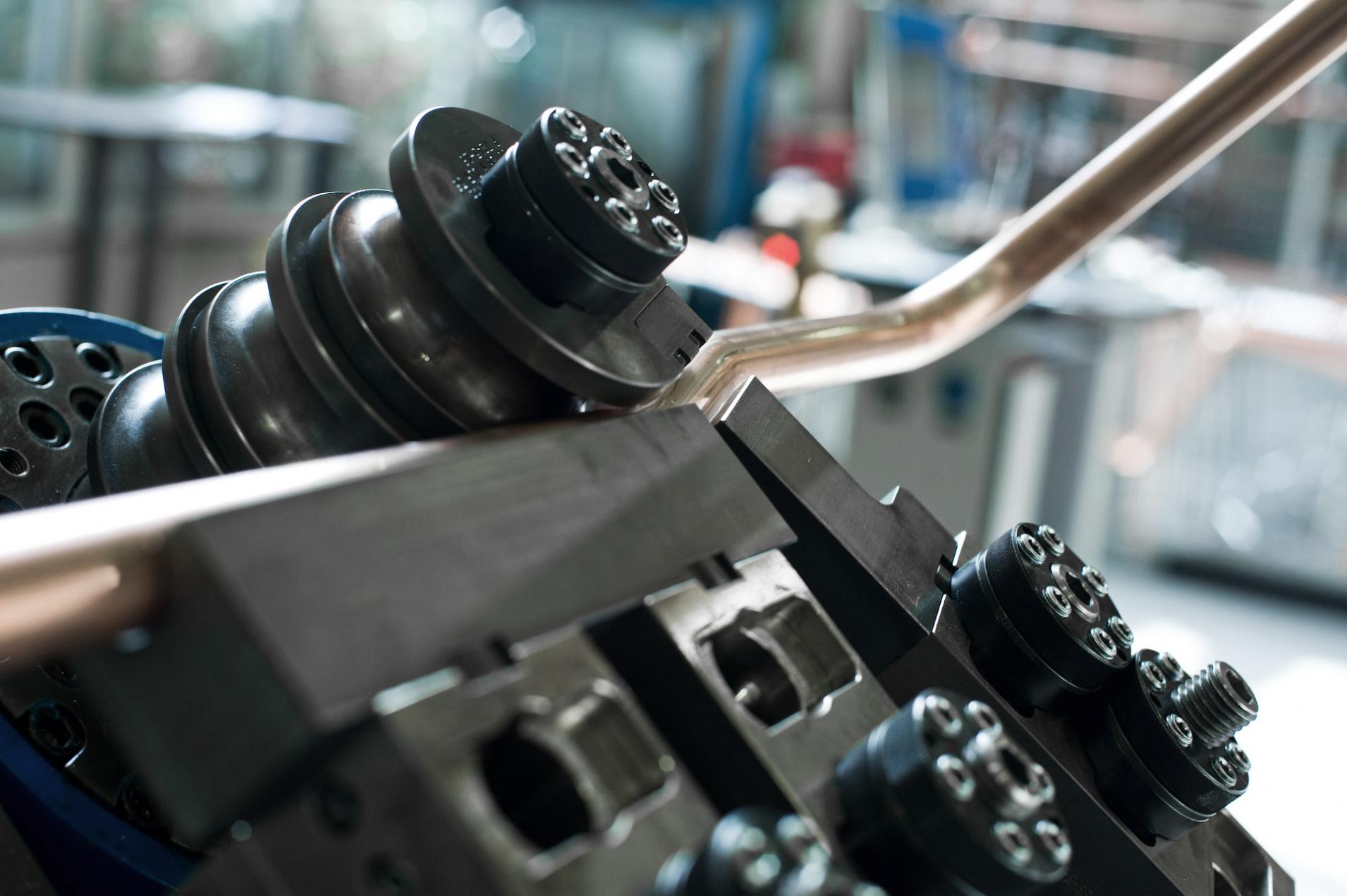

We have decades of production expertise in the manufacturing of ready-to-install pipe systems for the transport of fuels and refrigerants in buses and passenger cars. In the meantime, we have delivered tens of thousands of complete pipe systems to OEMs. Depending on customer requirements, we form pipes made from steel, stainless steel, copper, brass or aluminium on state-of-the-art CNC bending machines and provide the pipe ends with suitable and stable connections. Besides refrigerant and fuel lines, we can in this way also produce various other line types – for example, hydraulic lines, oil lines or coolant lines. With individually agreed logistics concepts, we contribute to a smooth production process at the customer.

Our range of services covers the following:

- Pipe bending with diameters of between 2 mm and 70 mm to suit the specified bending radius

- Bending of steel, stainless steel, copper, brass and aluminium pipes

- Attachment of connections by means of induction soldering and brazing

- Pipe end processing in accordance with the customer drawing

- Initial sampling of new lines

- Vehicle-related delivery (one-set flow), just-in-time or just-in-sequence

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Saarbrücken here.